Mining classification device

A classification device and mine technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the blockage of the discharge port, the impact of the discharge port on the classification accuracy, and the normal operation of the classification device. and other problems, to achieve the effect of narrow particle size distribution and high classification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be further clearly and completely described below in conjunction with the embodiments and the accompanying drawings.

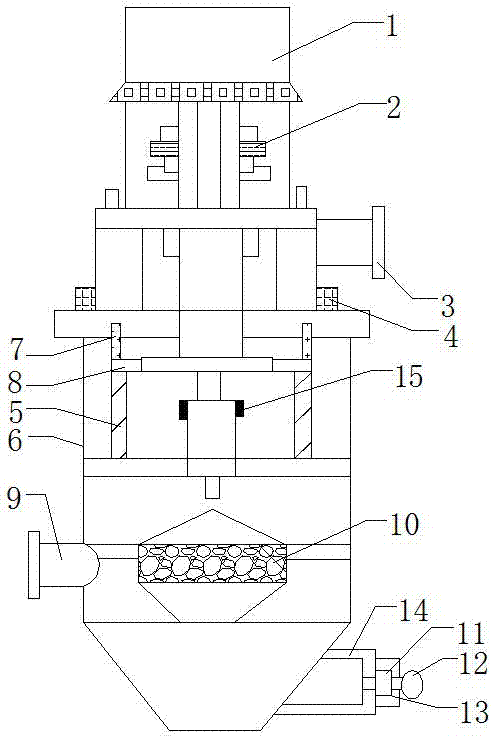

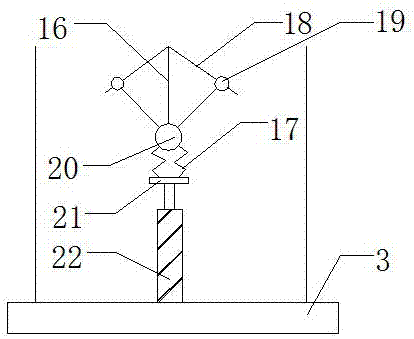

[0015] see figure 1 , figure 1 It is a schematic structural view of the present invention, a mining classification device, including a body 6 and a discharge port 3, the body 6 of the single-stage classification device is provided with an inspection door, and the inspection door is in the same position as the classification wheel 5 Correspondingly, the discharge port 3 includes a support rod 22, a fixed plate 21 is installed above the support rod 22, a spring 17 is arranged above the fixed plate 22, and a second hinge device 20 is installed above the spring 17, so that A second sliding rod 16 is installed above the second hinge device 20, a first hinge device 19 is installed on the right side of the second sliding rod 16, and a first sliding rod 18 is installed above the first hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com