Tea tree growth regulator and usage method thereof

A growth regulator, tea tree technology, applied in the directions of plant growth regulators, plant growth regulators, biocides, etc., can solve the problems of harm to human body, poor tenderness of fresh leaves, etc., to resist pests and diseases, increase aroma, and enhance emulsification. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

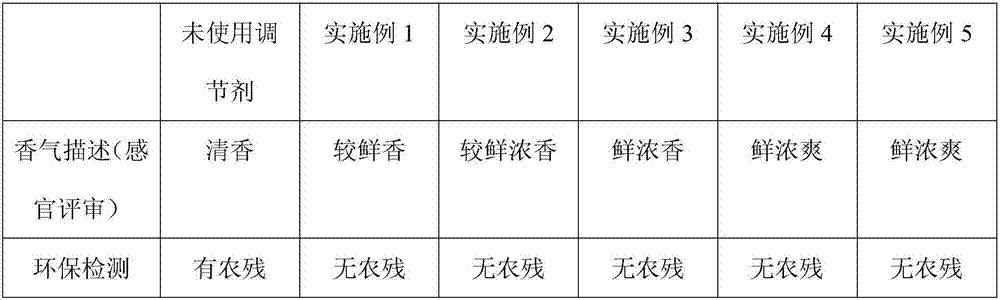

Examples

Embodiment 1

[0026] A kind of tea tree growth regulator, its raw material is made up of o-hydroxybenzoic acid, sorbitan monostearate and polyoxyethylene sorbitan stearate, described o-hydroxybenzoic acid, sorbitan monostearate and The weight proportion of polyoxyethylene sorbitan stearate is 1:0.8:0.8.

[0027] The using method of described tea tree growth regulator, concrete steps are as follows:

[0028] (1) configuration: O-hydroxybenzoic acid, sorbitan monostearate, polyoxyethylene sorbitan stearate and water are mixed in a ratio of 1:0.8:0.8:2000 to obtain a tea tree growth regulator;

[0029] (2) Spraying: the prepared tea tree growth regulator is sprayed on the tea tree leaf surface on a sunny day, sprayed once every day at 10 o'clock in the morning, and continuously sprayed for 2 days;

[0030] (3) Harvesting: The tea leaves are harvested three days after harvesting and spraying, and the harvested tea leaves are processed and produced according to conventional techniques and techn...

Embodiment 2

[0032] A kind of tea tree growth regulator, its raw material is made up of o-hydroxybenzoic acid, sorbitan monostearate and polyoxyethylene sorbitan stearate, described o-hydroxybenzoic acid, sorbitan monostearate and The weight proportion of polyoxyethylene sorbitan stearate is 1:0.9:0.9.

[0033] The using method of described tea tree growth regulator, concrete steps are as follows:

[0034] (1) configuration: o-hydroxybenzoic acid, sorbitan monostearate, polyoxyethylene sorbitan stearate and water are mixed in a ratio of 1:0.9:0.9:2000 to obtain a tea tree growth regulator;

[0035] (2) Spraying: the prepared tea tree growth regulator is sprayed on the tea tree leaf surface on a sunny day, sprayed once every day at 10 o'clock in the morning, and continuously sprayed for 3 days;

[0036] (3) Harvesting: The tea leaves are harvested three days after harvesting and spraying, and the harvested tea leaves are processed and produced according to conventional techniques and techn...

Embodiment 3

[0038] A kind of tea tree growth regulator, its raw material is made up of o-hydroxybenzoic acid, sorbitan monostearate and polyoxyethylene sorbitan stearate, described o-hydroxybenzoic acid, sorbitan monostearate and The weight ratio of polyoxyethylene sorbitan stearate is 1:1:1.

[0039] The using method of described tea tree growth regulator, concrete steps are as follows:

[0040] (1) configuration: o-hydroxybenzoic acid, sorbitan monostearate, polyoxyethylene sorbitan stearate and water are mixed in a ratio of 1:1:1:2000 to obtain the tea tree growth regulator;

[0041] (2) Spraying: the prepared tea tree growth regulator is sprayed on the tea tree leaf surface on a sunny day, sprayed once every day at 10 o'clock in the morning, and sprayed continuously for 4 days;

[0042] (3) Harvesting: The tea leaves are harvested three days after harvesting and spraying, and the harvested tea leaves are processed and produced according to conventional techniques and techniques.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com