Trunk rope winding equipment and use method of same

A tree trunk and rope winding technology, applied in the directions of botanical equipment and methods, application, plant protection cover, etc., can solve the problems of the gap between the straw rope and the straw rope, low work efficiency, and labor consumption, so as to ensure the winding accuracy and improve the efficiency. , the effect of reducing manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

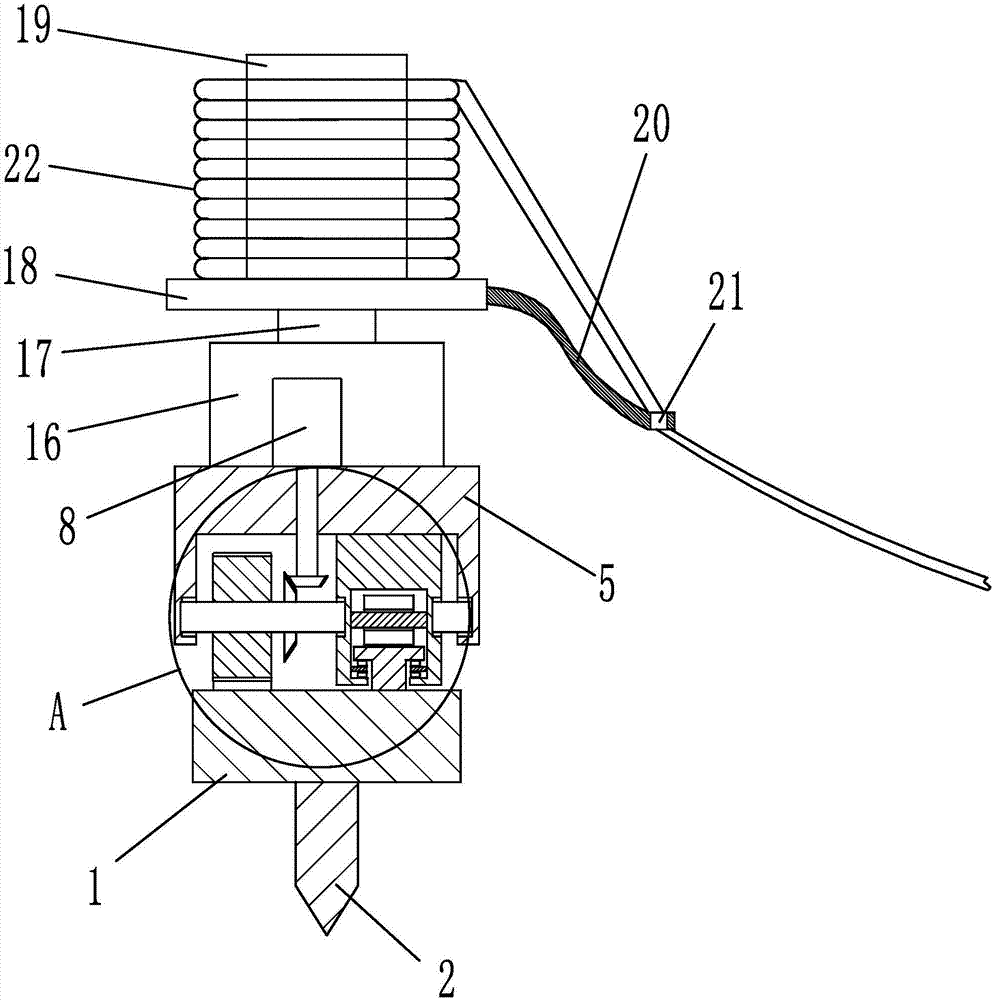

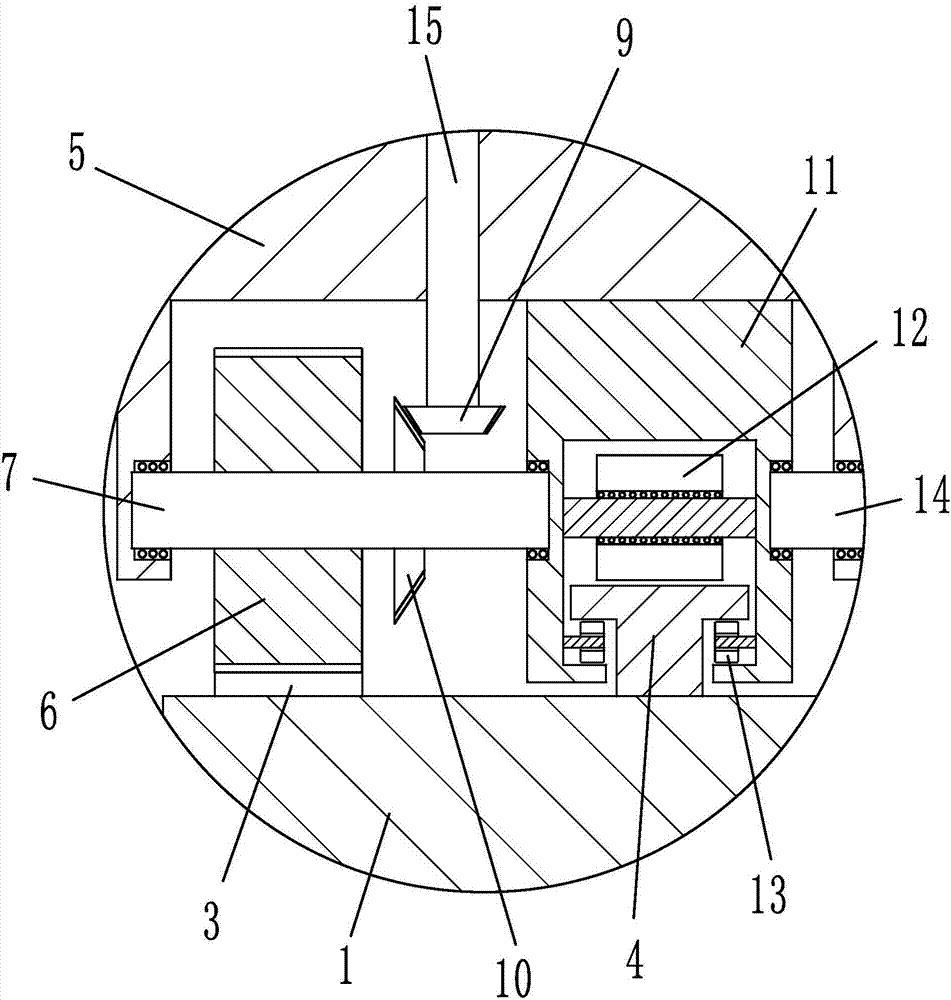

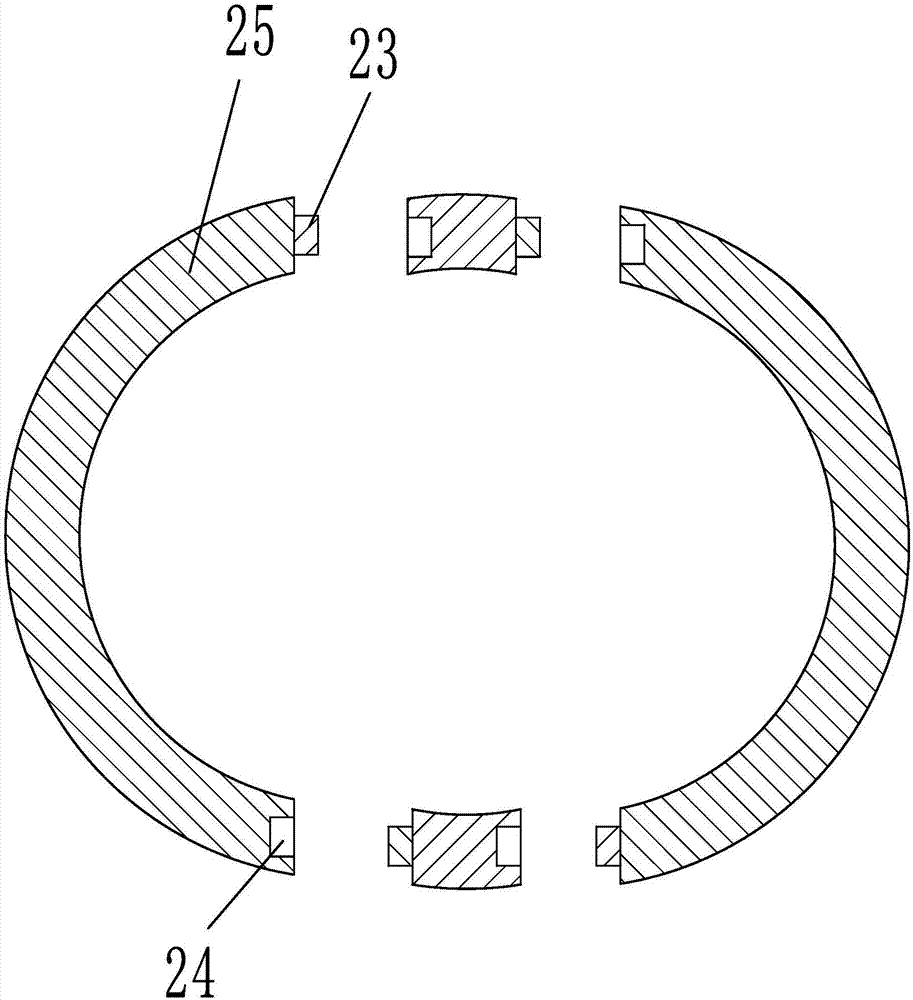

[0024] Embodiment 1: as figure 1 , 2 As shown, a tree trunk roping device includes: a bottom rail 1 for surrounding the trunk, a sliding device capable of moving on the bottom rail, and a lifting device for lifting. The upper end surface of the bottom rail is provided with a feed rack 3 and a limit track 4 equidistant from the feed rack, such as image 3 As shown, the bottom rail includes several arc-shaped splicing sections 25 , one end surface of the splicing section is provided with a positioning plug 23 , and the other end is provided with a positioning slot 24 matched with the positioning plug of another splicing section. The sliding device includes a sliding seat 5, a feed gear 6 meshing with the feed rack, and a sliding limit seat 11 matched with the limit track. The feed gear is rotatably connected to the sliding seat, and the sliding limit seat is fixed to the sliding seat Connected, the upper end surface of the sliding seat is provided with a drive motor 8 for driv...

Embodiment 2

[0027] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 4 , 5 As shown, the end of the sliding limit seat close to the driving shaft is provided with a limit hole 26 matched with the drive shaft, the end of the drive shaft close to the limit hole is provided with a buffer hole 27, and a buffer ball 28 is arranged in the buffer hole, and the buffer ball Fitted with the bottom surface of the limiting hole, a buffer spring 29 with a diameter smaller than the buffer ball is arranged between the buffer ball and the bottom surface of the buffer hole. The driving shaft is located in the limit hole and connected with the wall of the limit hole in rotation. A buffer hole is arranged at the end of the drive shaft close to the limit hole. A buffer ball is arranged in the buffer hole, and a buffer spring is used to push the buffer ball against the limit hole. at the bottom. When the sliding device slides, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com