Pulsed excitation-based dynamic thermal chromatography imaging detection system and method

An imaging detection and pulse excitation technology, which is applied in the field of dynamic thermal tomography detection systems based on pulse excitation, can solve the problems of insensitive detection of defects in the surface layer and superficial layer of materials, and inability to form a three-dimensional geometric shape of material defects, reducing the The effect of lateral thermal diffusion, efficient detection, and improved detection signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

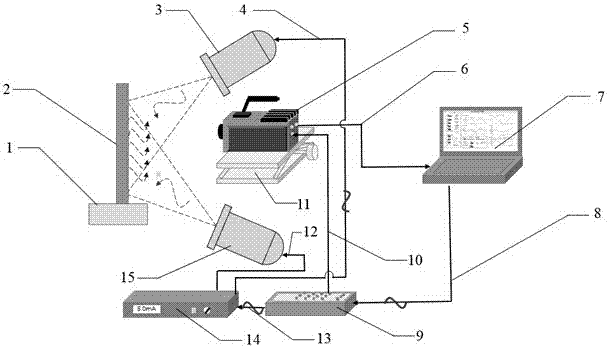

[0033] Specific implementation mode 1: This implementation mode records a dynamic thermal tomography detection system based on pulse excitation (such as figure 1 shown), the system includes a three-dimensional mobile platform 1, a test sample 2, a first xenon lamp 3, a power cord 4 for the first xenon lamp, an infrared thermal imager 5, an Ethernet cable 6, a computer 7, a USB data cable 8, and data acquisition Card (with arbitrary function generation function) 9, BNC trigger signal line 10, vertical lifting platform 11, second xenon lamp power line 12, BNC data line 13, xenon lamp power supply 14, second xenon lamp 15;

[0034] The signal output end of the infrared thermal imager 5 is connected with the signal input end of the computer 7 through the Ethernet line 6, and the signal output end of the computer 7 is connected with the signal input end of the data acquisition card 9 through the USB data line 8, and the data acquisition Card 9 signal output terminal one is connecte...

specific Embodiment approach 2

[0035] Embodiment 2: A method for realizing dynamic thermal tomography detection based on pulse excitation by using the system described in Embodiment 1. The specific steps of the method are as follows:

[0036] Step 1: Determine the test sample 2 to be measured, and place it on the three-dimensional mobile platform 1;

[0037] Step 2: Turn on the dynamic thermal tomography detection system based on pulse excitation. This step includes turning on the computer 7, the data acquisition card 9, the xenon lamp power supply 14 and the thermal imaging camera 5;

[0038] Step 3: Correct the non-uniformity of the infrared thermal imager 5, and then use the computer 7 to control the software to assist the infrared thermal imager 5 to adjust the imaging detection field of view, and adjust the three-dimensional mobile station 1 to make the image clear;

[0039] Step 4: The computer 7 controls the data acquisition card 9 and then controls the xenon lamp power supply 14, and then controls t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com