Digital-ray-direct-imaging interface morphology detection system for composite material and method

A digital ray and composite material technology, applied in the direction of material analysis using radiation, can solve problems such as the inability to determine the weak bonding area, and achieve the effects of easy promotion and use, good use effect, and novel and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

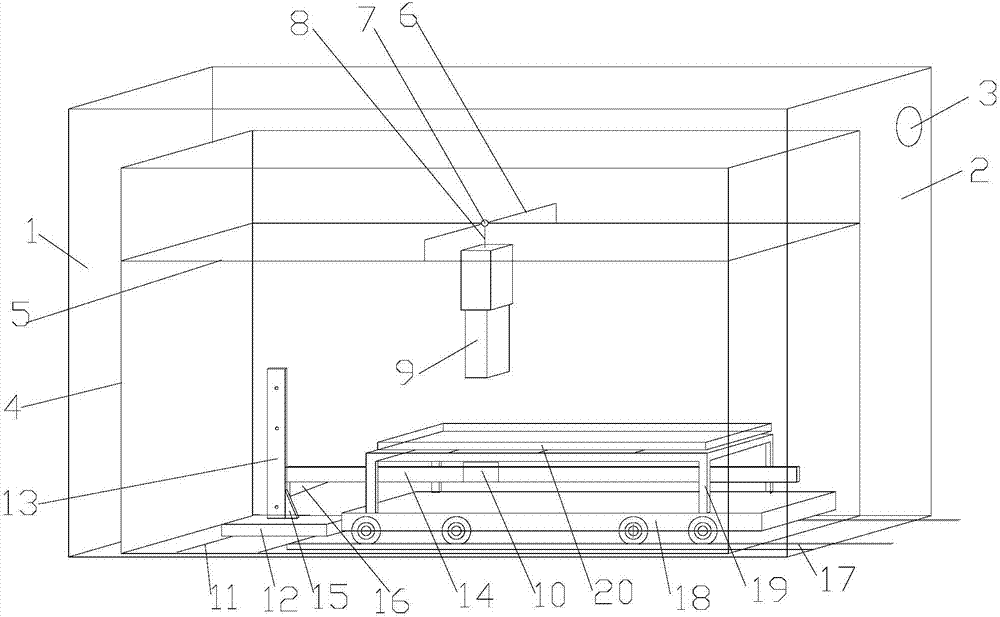

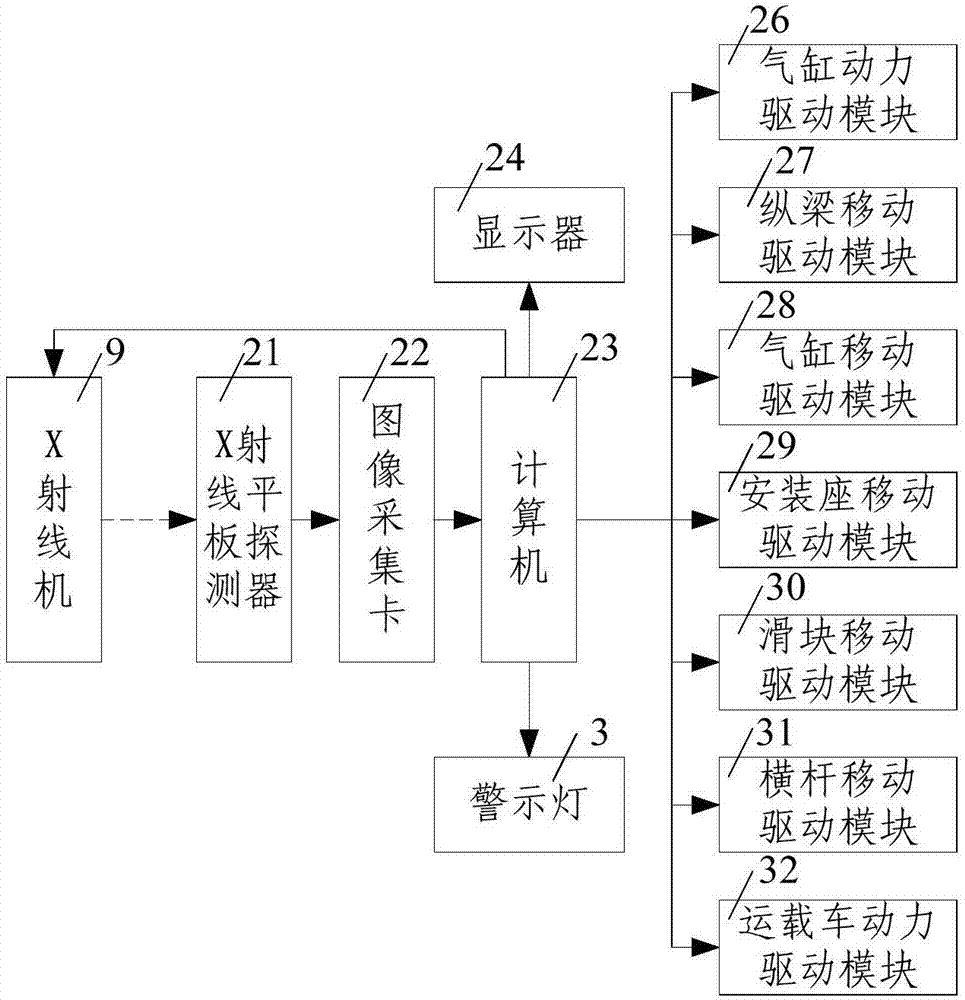

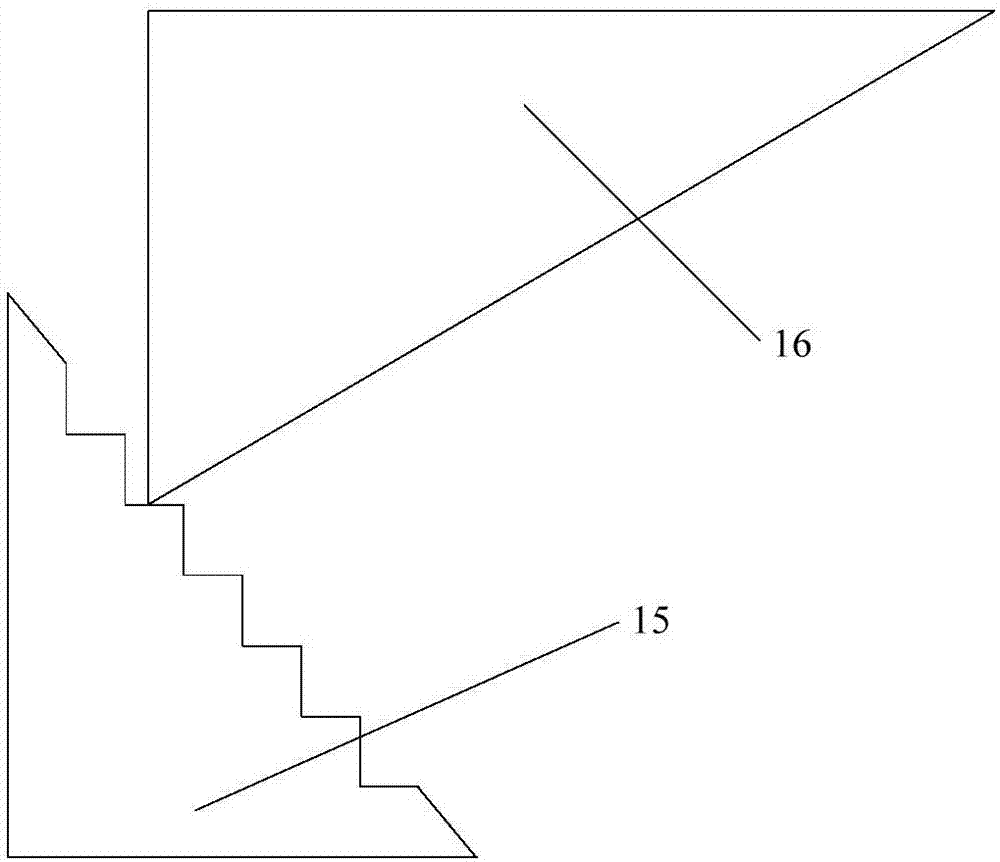

[0048] Such as figure 1 and figure 2 As shown, the digital ray direct imaging composite material interface morphology detection system of the present invention includes a detection room 1, a direct imaging device arranged in the imaging area of the detection room 1, and a vehicle 18 extending into the imaging area. The moving horizontal rail 17 and the processor for controlling the direct imaging device to automatically complete image acquisition and image processing to the collected images, a cube support frame 4 is arranged outside the imaging area, and the middle and upper part of the cube support frame 4 And two equal-height crossbeams 5 are arranged along the length direction of the detection chamber 1. The direct imaging device includes an X-ray machine 9, an X-ray flat panel detector 21, an X-ray machine movement mechanism that drives the X-ray machine 9 to move, and an X-ray machine that drives the X-ray machine. The moving mechanism of the X-ray flat panel detecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brightness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com