System for rapidly determining accurate imaging scheme for belt material defect detection

A technology of defect detection and calibration system, which is applied in the direction of optical test defects/defects, can solve complex test work and other problems, and achieve the effect of improving test efficiency, accurate and scientific design scheme, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

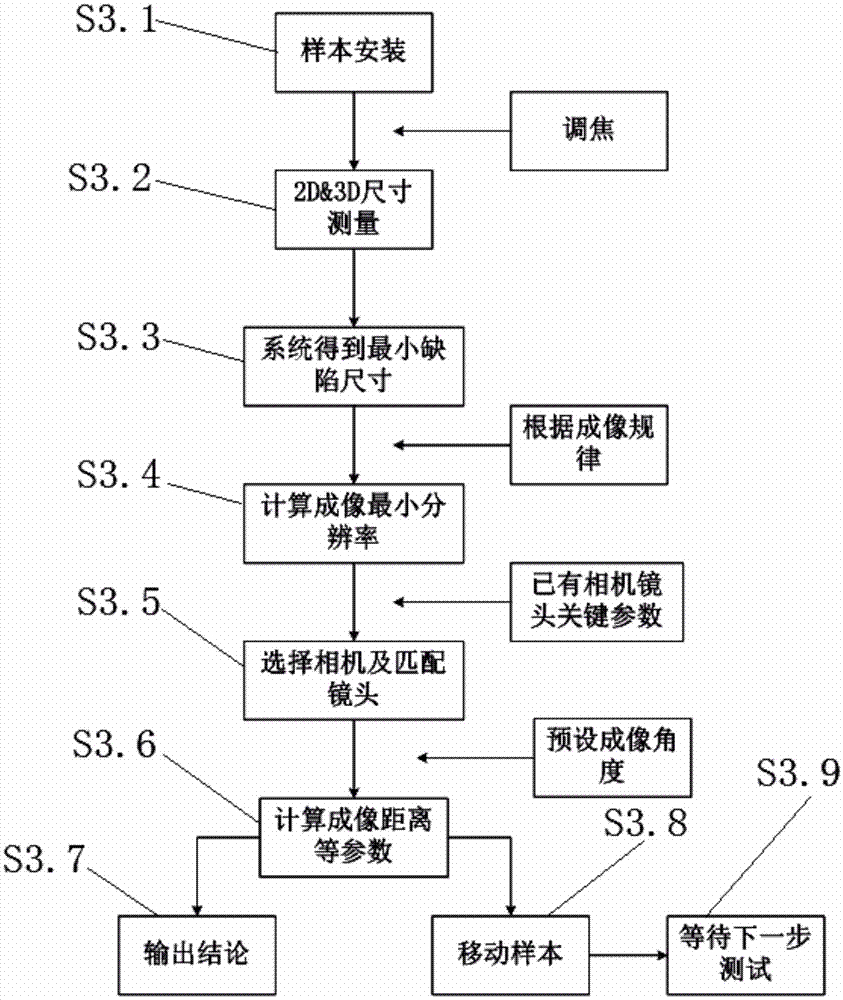

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

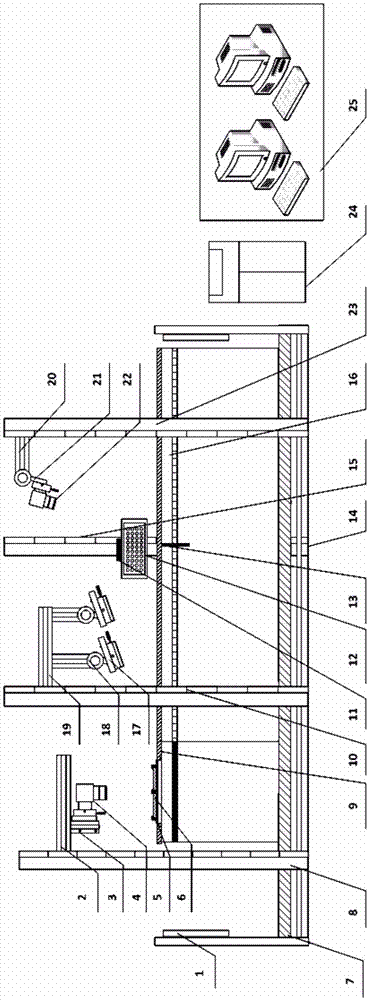

[0020] refer to figure 1 , the invention discloses a system for quickly determining an accurate imaging scheme for strip defect detection, which mainly includes four main modules, namely, an accurate calculation resolution test module, a composite imaging system module, a calibration system module, and imaging parameter calculation and scheme Determine the module.

[0021] The above four modules are composed of multiple components, including:

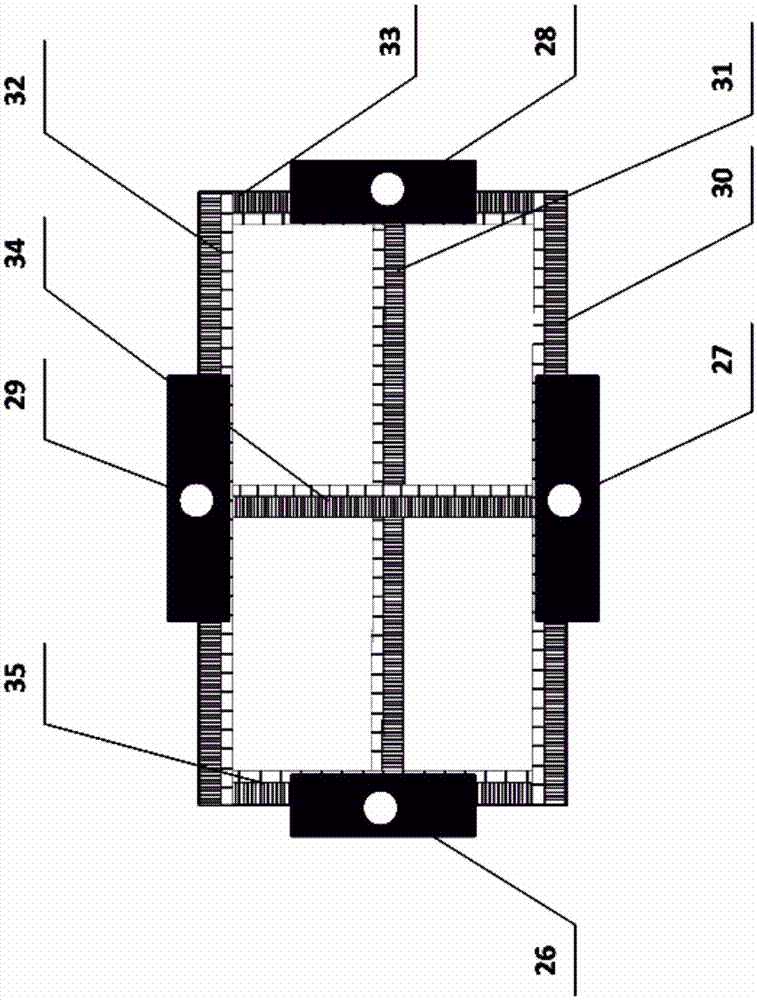

[0022] Safety fence sensor 1, X-axis adjustable bracket 2, 3D camera fine-tuning mechanism 3, high-precision 3D camera 4, sample to be tested 5, movable stage with fixture and ruler 6, safety fence 7, Y with ruler Axis adjustable camera bracket 8, mobile stage guide rail 9, Y-axis adjustable light source bracket with scale 10, light source adjuster that can adjust distance and small a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com