Device for achieving material forced shrinkage function through differential mechanisms

A technology of differential mechanism and shrinkage function, applied in the field of rubber and plastic machinery, can solve the problems of rubber stacking, rubber material not meeting the process requirements, and affecting product quality, so as to restore the shape, improve the quality of the tread, and avoid stretching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

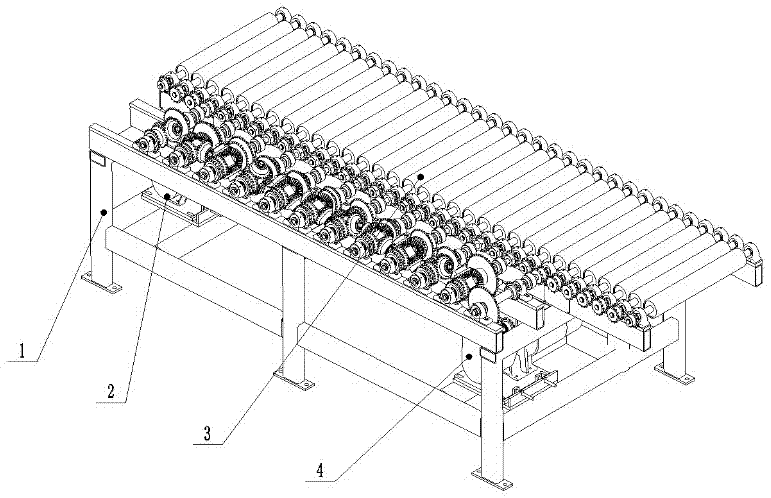

[0023] like figure 1 As shown, a device that uses a differential mechanism to realize the function of forced shrinkage of materials includes a support frame 1, a front frequency conversion motor 2, a roller with a bevel gear differential mechanism 3, and a rear frequency conversion motor 4; the front frequency conversion The motor 1 is installed inside the support frame 2; the rollers 3 with bevel gear differential mechanism are distributed horizontally above the support frame 1; the rear variable frequency motor 4 is fixed under the roller at the right end of the support frame 1; the front variable frequency motor and the rear The variable frequency motors 4 all have even encoders (not shown in the figure).

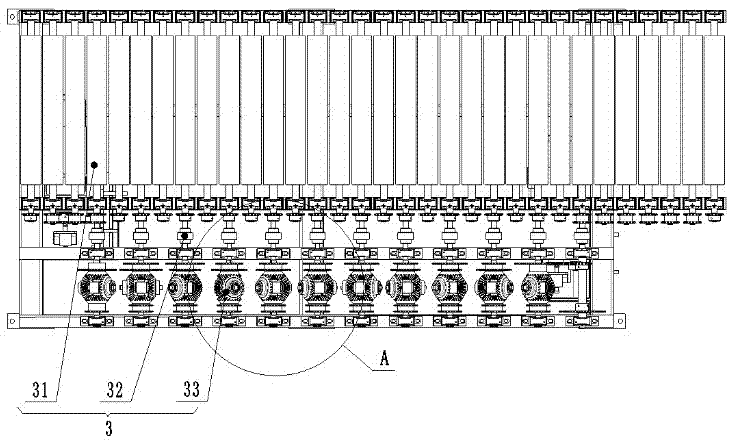

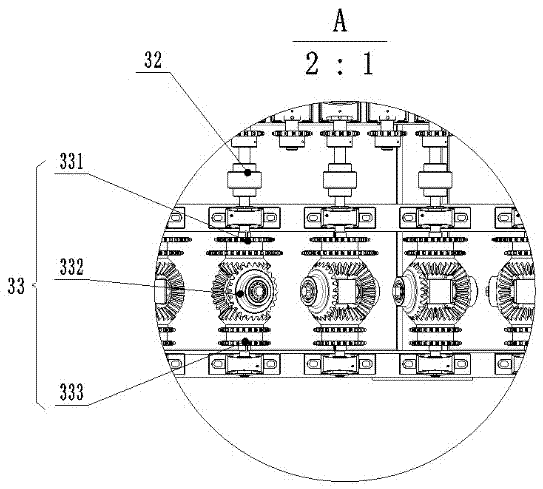

[0024] refer to figure 2 , shows the schematic diagram of the roller 3 with bevel gear differential mechanism of the present invention, the roller with bevel gear differential mechanism, 3 includes transmission roller 31, shaft coupling 32, bevel gear differential mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com