Laser cutting film sticking machine and utilization method thereof

A laser cutting and film laminating machine technology, which is applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems that a single film can not adapt to multiple processes, the equipment occupies a large area, and the degree of automation is low. The effect of small area, fast cutting speed and strong maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

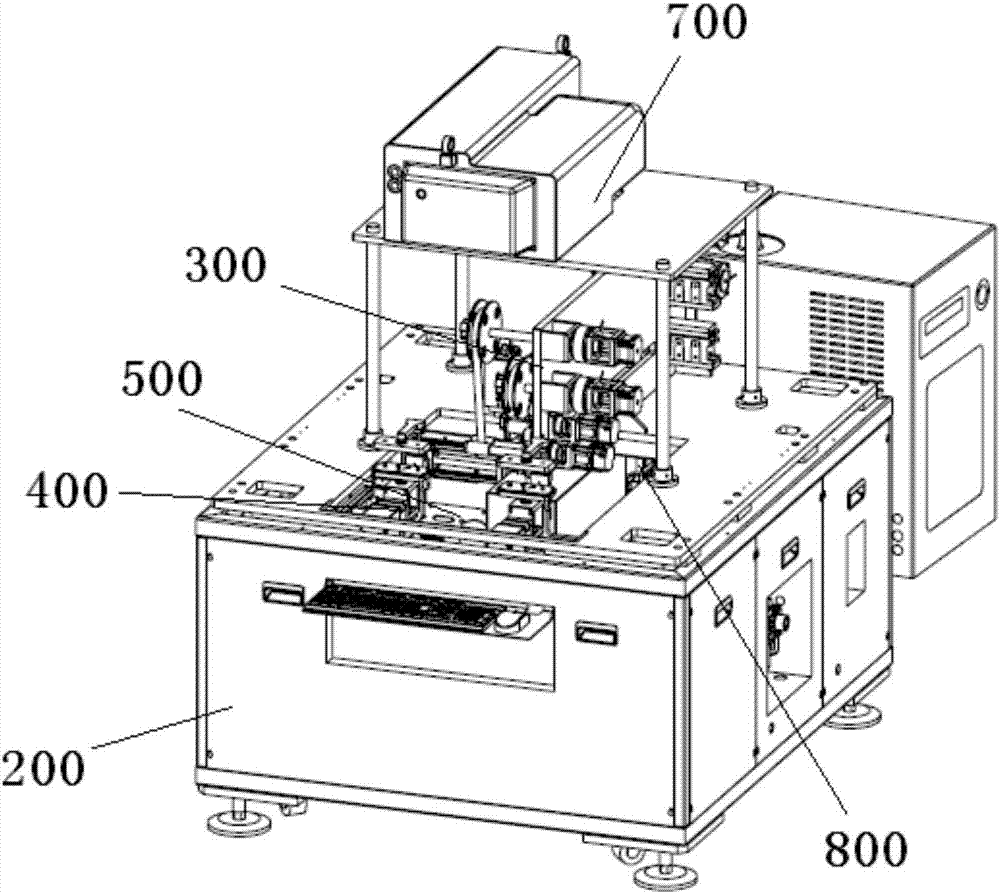

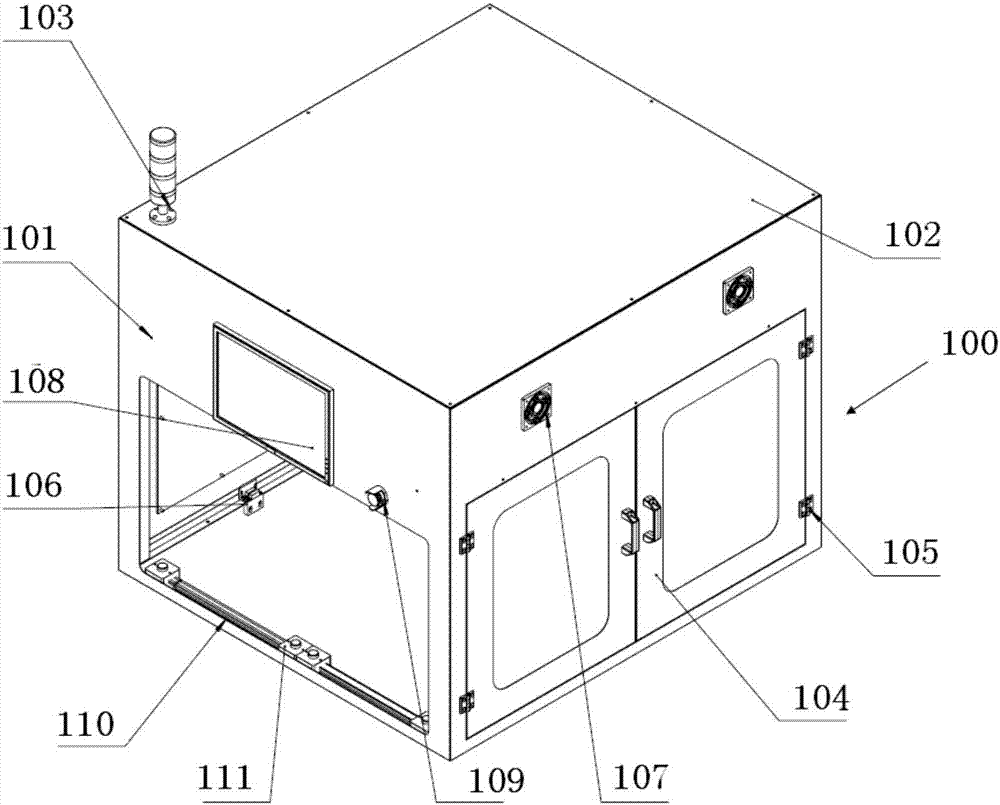

[0028] Such as figure 1 , figure 2 As shown, the present invention provides a laser cutting and film laminating machine, which is mainly used in the production and assembly fields of electronic industries such as mobile phones, to protect the frame of mobile phones and prevent damage to the frames of electronic products such as mobile phones during production and assembly. The present invention includes an upper frame mechanism 100 , a lower frame mechanism 200 , a film roll mechanism 300 , a motion mechanism 400 , a rotation mechanism 500 , a clamp mechanism 600 , a laser mechanism 700 and a control mechanism 800 . The upper frame mechanism 100 is fixed on the upper part of the lower frame mechanism 200 by bolts, the film rolling mechanism 300, the moving mechanism 400, the rotating mechanism 500, the clamp mechanism 600 and the laser mechanism 700...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com