Molecular imprinting catalytic membrane capable of selectively degrading ciprofloxacin and preparation method

A molecularly imprinted and ciprofloxacin technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems affecting molecularly imprinted polymers and achieve highly selective degradation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

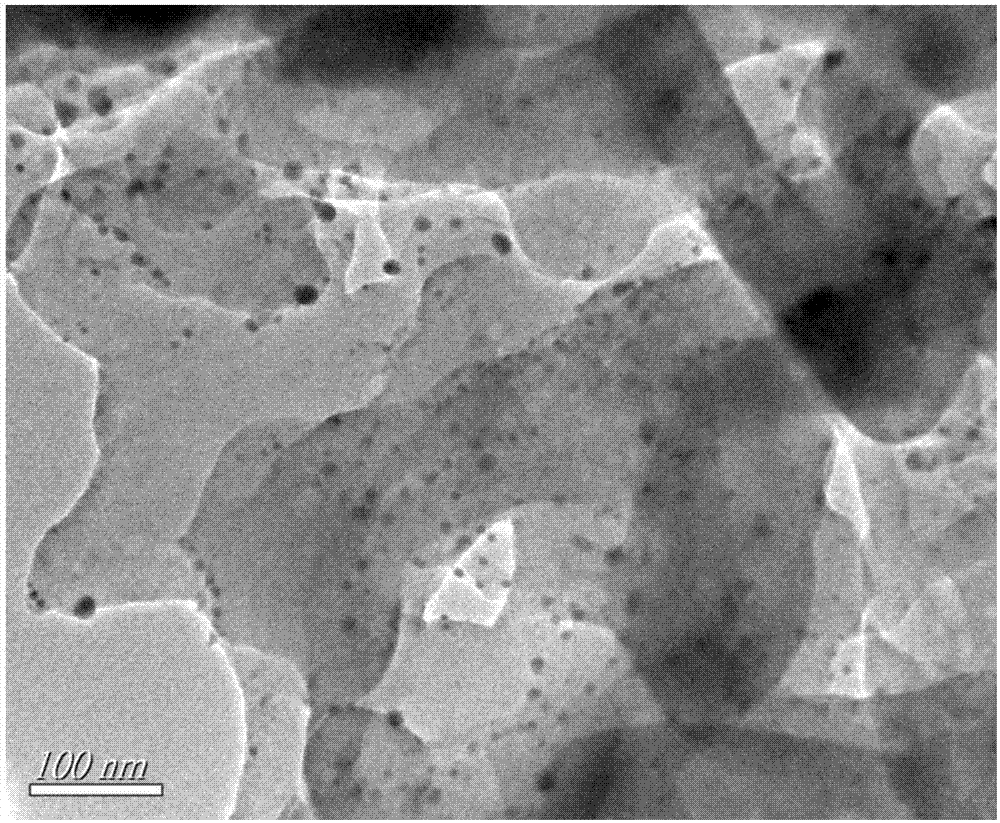

[0034] Embodiment 1: (1) Ag / Au / C 3 N 4 Catalyst preparation

[0035] First, 1 g of polyvinyl alcohol (PVA) was dissolved in 99 mL of deionized water, and 1 g of chloroauric acid (HAuCl 4 4H 2 O) dissolved in 10mL deionized water, take 0.157g silver nitrate (AgNO 3 ) was dissolved in 0.418mL chloroauric acid solution, and then the above mixed solution was slowly added dropwise to 4mL of 1% PVA aqueous solution with a mass fraction of 0.1mol L -1 NaBH 4 Add the aqueous solution dropwise to the above solution, and finally take 1g of graphite-like carbonized nitrogen (g-C 3 N 4 ) was dissolved in the above solution, stirred by magnetic force for 1 h, then washed three times with deionized water and absolute ethanol, and dried at 120 °C for 24 h after centrifugation to finally obtain the Ag / Au / C3N4 catalyst. As a comparison, the same Methods and steps for the synthesis of Ag / C 3 N 4 Catalyst, but do not add chloroauric acid solution; synthesize Au / C with the same method an...

Embodiment 2

[0040] Embodiment 2: (1) by changing the kind of photocatalyst (Ag / Au / C 3 N 4 , Ag / C 3 N 4 and Au / C 3 N 4 ) to examine the effect of different catalysts on photocatalytic degradation, the results show that Ag / Au / C 3 N 4 The degradation efficiency of the catalyst to ciprofloxacin is the highest, which can reach more than 90%. So the catalyst chosen in the experiment is Ag / Au / C 3 N 4 catalyst.

[0041] (2) By changing Ag / Au / C 3 N 4 The amount of photocatalyst (0.2g, 0.3g, 0.4g) is used to examine the influence of catalyst dosage on photocatalytic degradation. The results show that when the catalyst dosage is 0.3g, the volume of ciprofloxacin solution is 70mL, and the concentration is 20mg L -1 When , it has the highest degradation efficiency to ciprofloxacin, which can reach more than 92%. Therefore, the amount of catalyst selected in the experiment was 0.3 g.

[0042] (3) Molecularly imprinted catalytic membrane prepared with 0.3g photocatalyst degrades different c...

Embodiment 3

[0043] Embodiment 3: Use the photocatalytic membrane prepared in (2) in Example 1 to degrade the mixed solution of ciprofloxacin and interfering substance (gatifloxacin) of the same concentration respectively, and then calculate its degradation efficiency by calculating the degradation efficiency of different substances Selectivity coefficients for different substances.

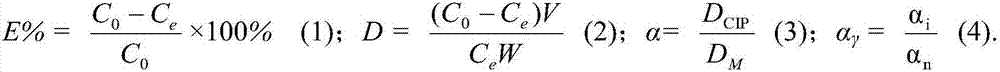

[0044]

[0045] where C 0 , C e are the initial and degraded concentrations of ciprofloxacin (mg L -1 ); D is the distribution coefficient, D CIP ,D M are the partition coefficients of ciprofloxacin and interfering substances, respectively; α is the selectivity coefficient, α i , α n are the selectivity coefficients of ciprofloxacin and gatifloxacin, respectively, α r is the relative selectivity coefficient. The experimental results showed that the degradation efficiency of ciprofloxacin by the molecularly imprinted photocatalytic membrane was significantly higher than that of other contrasting subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com