Gas insulated power transmission line

A transmission line, gas insulation technology, applied in the direction of busbar/line layout, electrical components, busbar installation, etc., can solve the problems of affecting the normal use of conductors, conductor damage, and easy wear and tear of conductor installation, to achieve a good limit effect, Effect of preventing movement and increasing insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

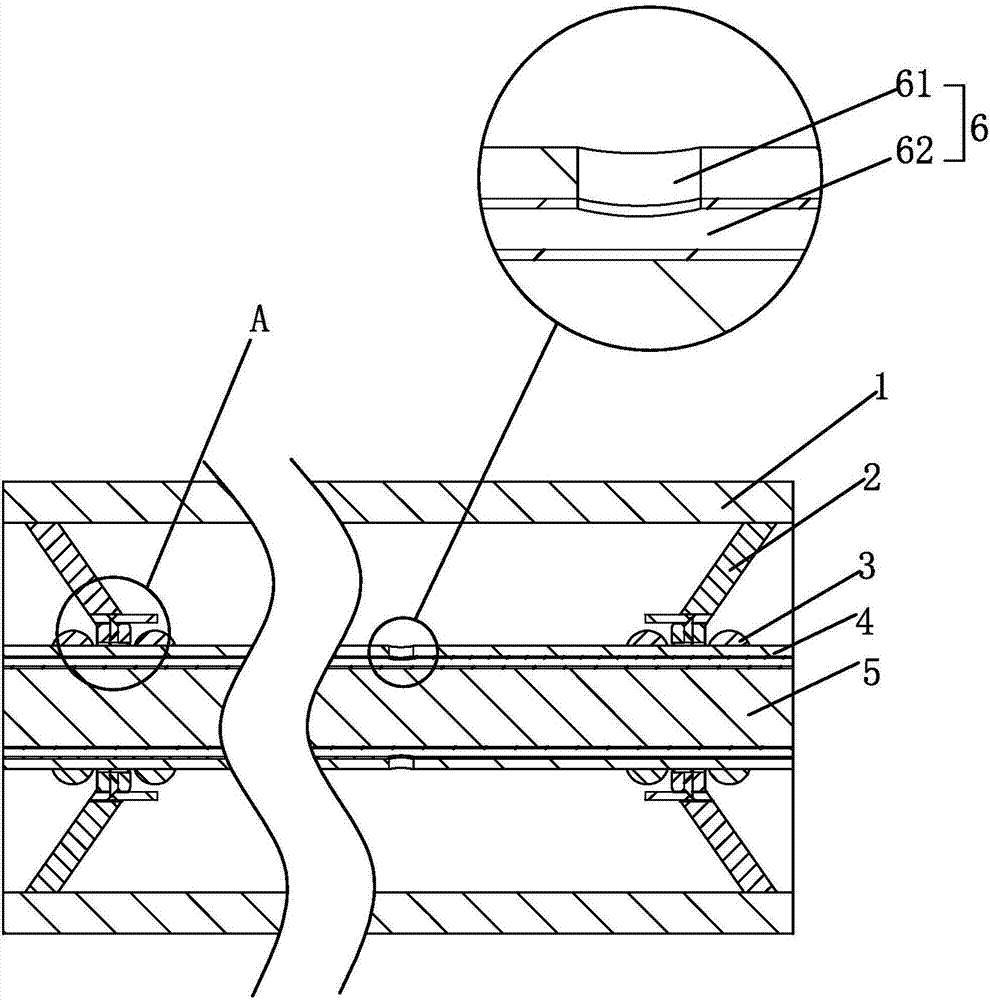

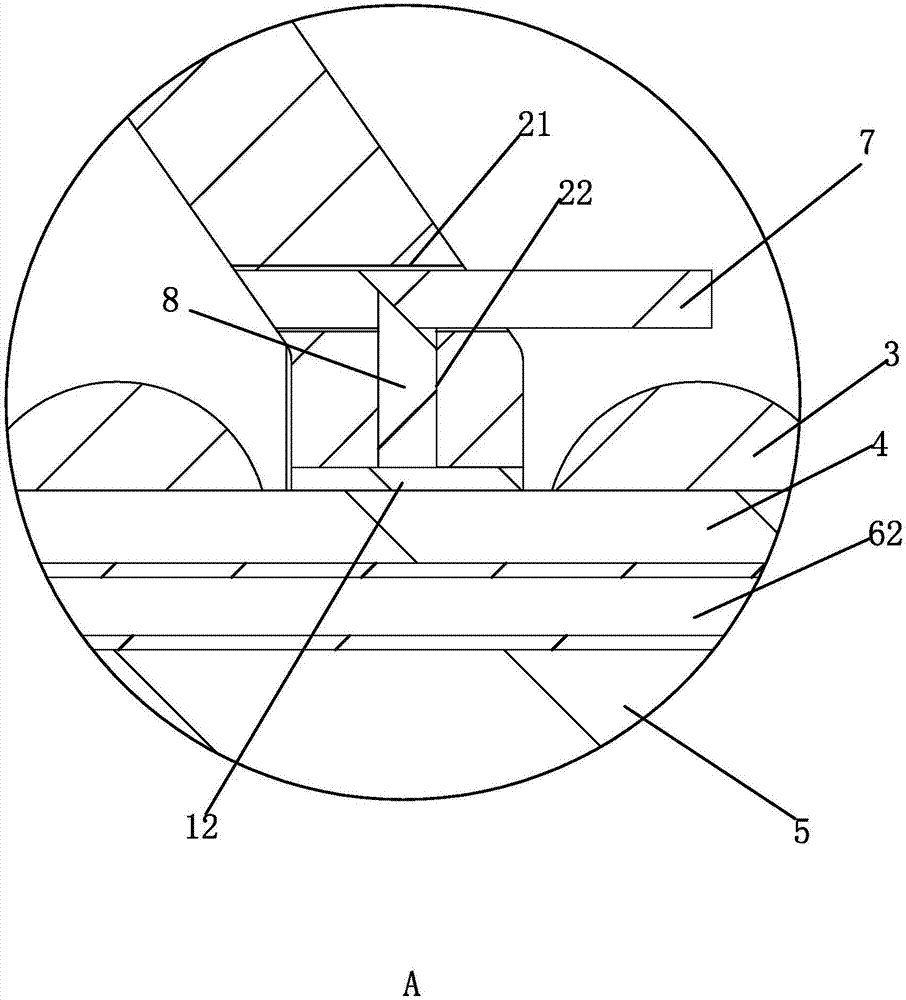

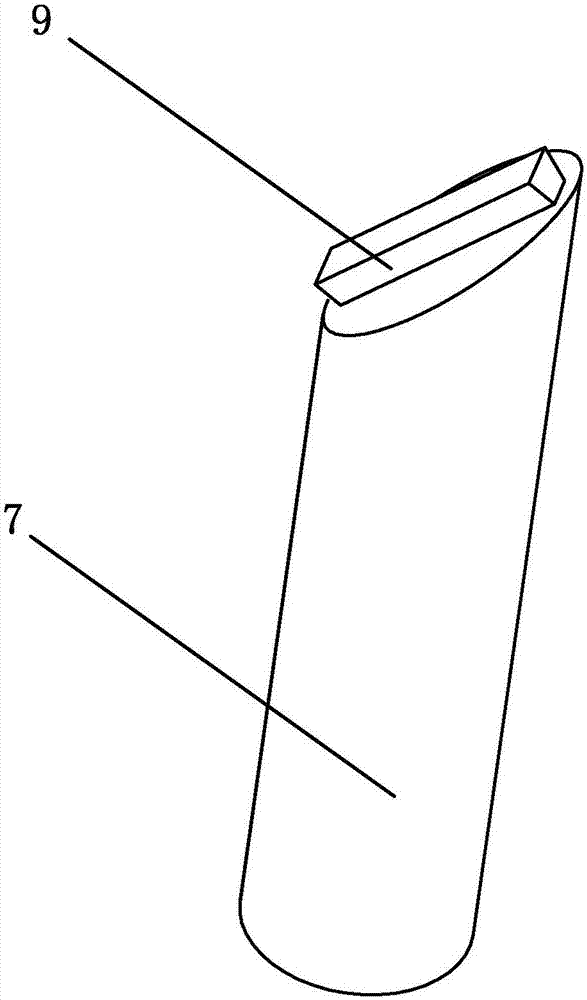

[0039] A gas insulated transmission line, with reference to figure 1 and figure 2, including several connected pipe units, the pipe unit includes a cylindrical shell 1 and pot insulators 2 fixed at both ends of the pipe unit, and a through hole 65 is provided on the pot insulator 2, and the penetration direction of the through hole 65 Parallel to the axial direction of the shell 1; a protective cover 4 is provided in the shell 1, and the protective cover 4 respectively passes through the through holes 65 on the two basin insulators 2. The shape of the through holes 65 is circular. The side wall of 65 is covered with a rubber strip, and the cross-sectional shape of the rubber strip is a circular ring arranged concentrically with the through hole 65 . At the end of the basin-type insulator 2 opposite to the housing 1, there are four extruding parts that squeeze the sealing strip 12 under the action of insulating compressed gas to increase the sealing between the sealing strip ...

Embodiment 2

[0045] A gas insulated transmission line, with reference to Figure 5 and Figure 6 The difference between the present embodiment and the first embodiment is that the clamping member 6 in the present embodiment includes a through hole 65 provided on the side wall of the protective cover 4, and the through hole 65 is sealed and slidable, and one end can be connected to the conductor 5 The clamping block 63 and the elastic member sleeved on the clamping block 63 with the side walls against each other; wherein, the elastic member is a spring 64, one end of the spring 64 is fixedly connected with the clamping block 63, and the other end is connected with the side wall of the through hole 65 Fixedly connected: one end of the clamping block 63 opposite to the protective sleeve 4 is covered with an elastic layer 10, the elastic layer 10 is made of rubber material, and several convex points 11 are arranged on the end of the elastic layer 10 opposite to the protective sleeve 4.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com