Rotary bearded zinc electrode/gilled air electrode zinc air battery

A zinc-air battery and air electrode technology, which is applied in the direction of fuel cell half-cells and primary battery-type half-cells, can solve the problems of reducing the utilization rate of raw materials, increasing the internal resistance of batteries, obstacles, etc., and achieving economical production methods , easy scale production, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

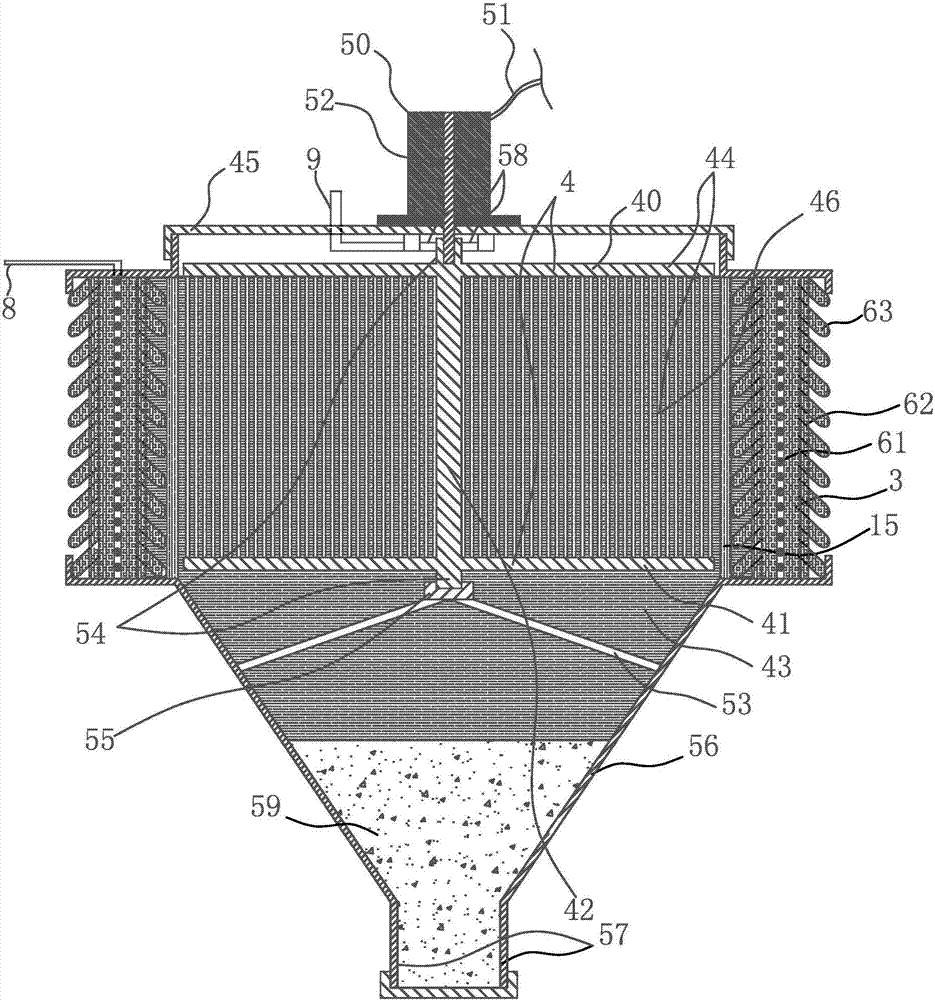

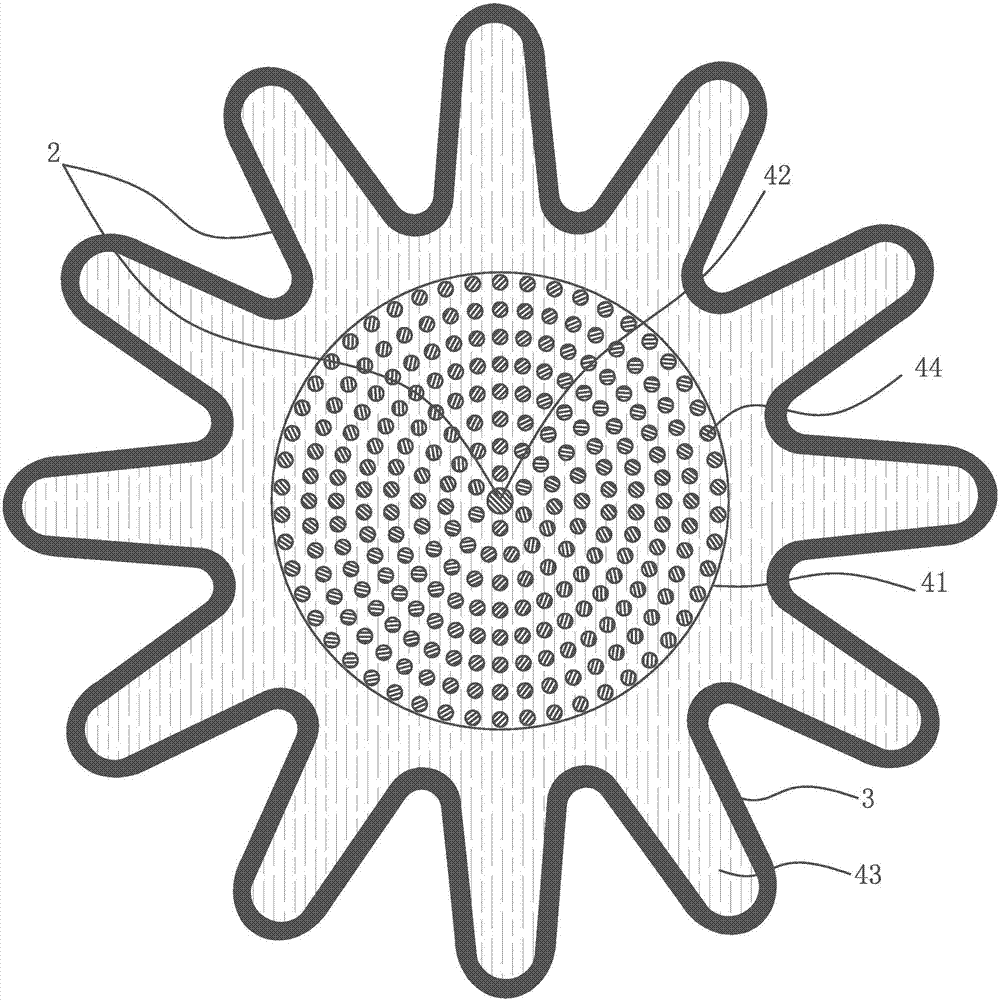

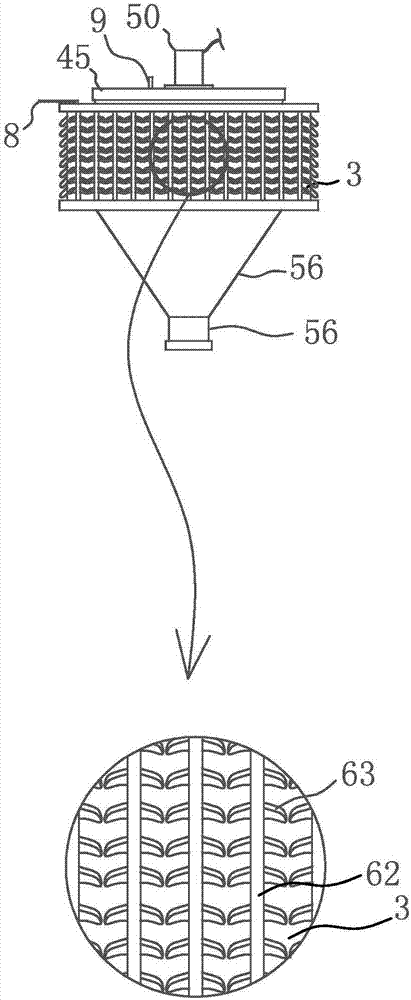

[0014] like Figure 1-3 Shown, a kind of spin whisker shape zinc electrode gill shape air electrode zinc-air battery, comprises battery reaction tank (2) and air electrode lead-out wire (8), zinc electrode lead-out wire (9), is characterized in that: battery reaction tank ( 2) The upper opening is open, and is provided with a movable reaction tank cover (45); the side of the battery reaction tank (2) is surrounded by the air electrode (3) into a star shape, and a gill-shaped cover is provided on the surface of the air electrode (3). Protrusion (60); the bottom of the battery reaction tank (2) is provided with a cone (56), and the lower end of the cone (56) is provided with a zinc oxide discharge port (57); the battery reaction tank (2) is filled with electrolytic liquid (43), and is provided with a zinc electrode (44)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com