Hydrogen preparation, storage and injection integral machine

An all-in-one hydrogen storage technology, applied in fuel cells, electrochemical generators, electrical components, etc., can solve the problems of high cost, large hydrogen production equipment, inconvenient, etc., to reduce gas filling costs and improve gas-liquid separation Efficiency, the effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

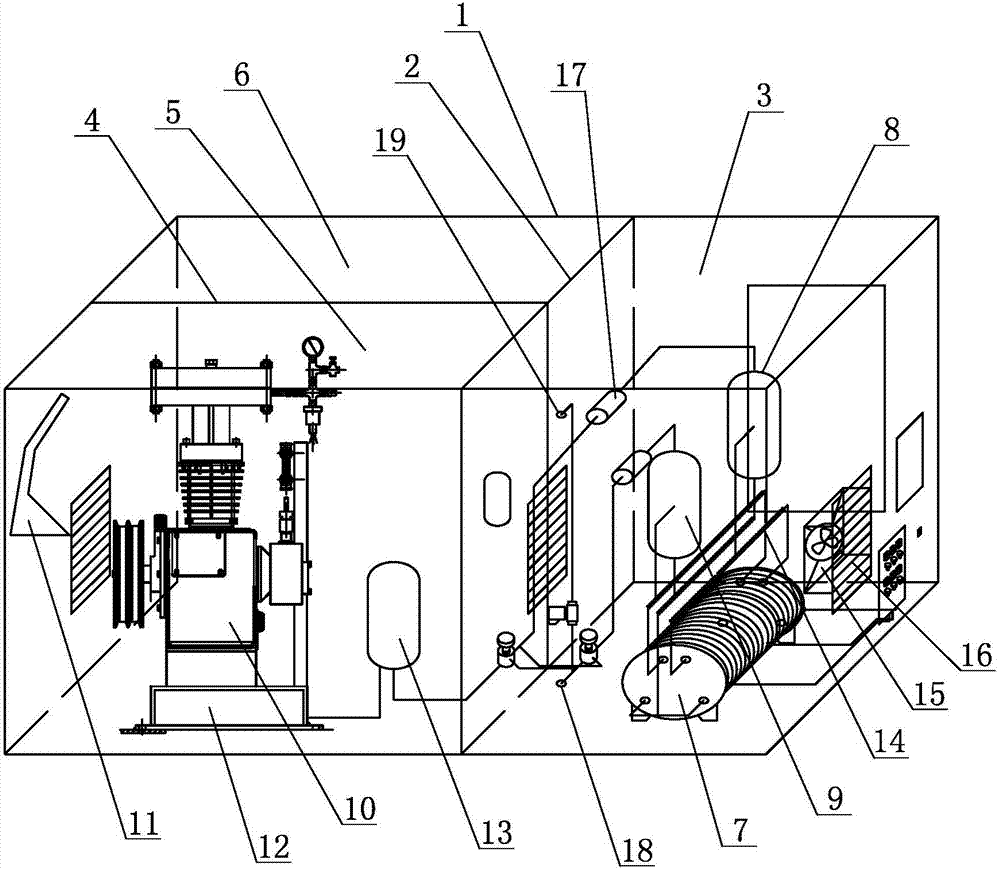

[0027] Embodiment one: see Figure 1~4 As shown, a hydrogen production, storage and filling integrated machine includes a box body 1, a vertical partition 2 is provided in the middle of the box body 1, and the vertical partition board 2 separates the box body 1 into hydrogen production cavity 3 and filling control cavity, the filling control cavity is provided with a transverse partition 4, and the horizontal partition 4 divides the filling control cavity into a filling cavity 5 and a control cavity 6; A hydrogen production device is provided in the hydrogen production chamber 3, a control device is provided in the control chamber 6, a filling device is provided in the filling chamber 5, and the control device is connected with the filling device and the hydrogen production device connected, the control device controls the work of the filling device and the hydrogen production device;

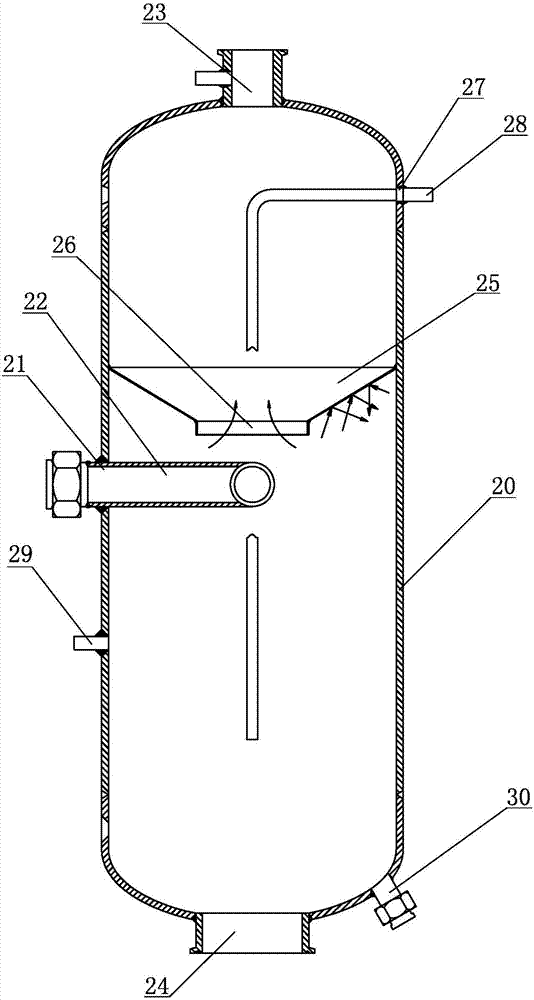

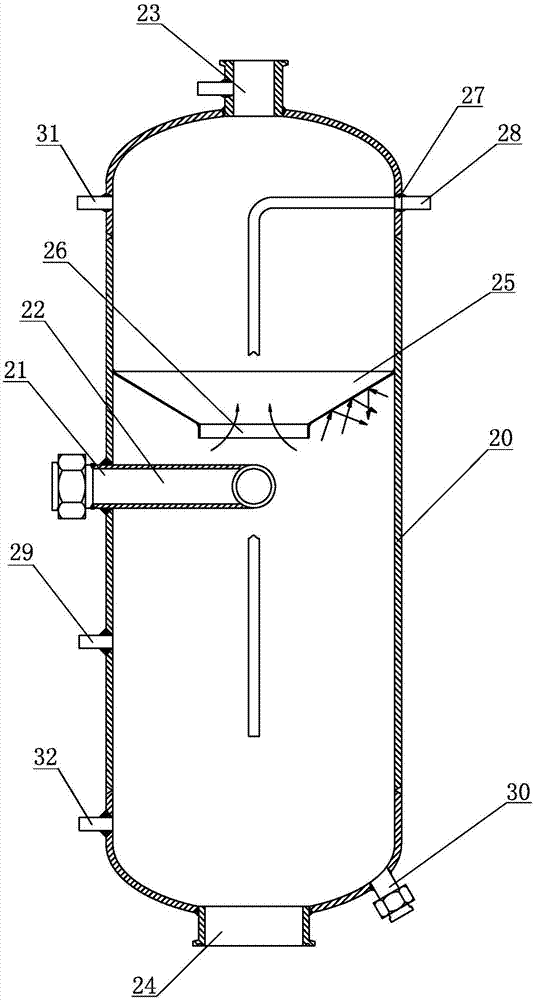

[0028] The hydrogen production device includes a liquid electrolyzer 7, a cooling device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com