Infrared absorber based on dielectric microcolumn array and preparation method thereof

A technology of micro-column array and absorber, which is applied in the field of infrared absorber, can solve the problems of low quality factor of absorber and unstable absorption peak wavelength, etc., and achieve the effect of high absorption, high quality factor and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

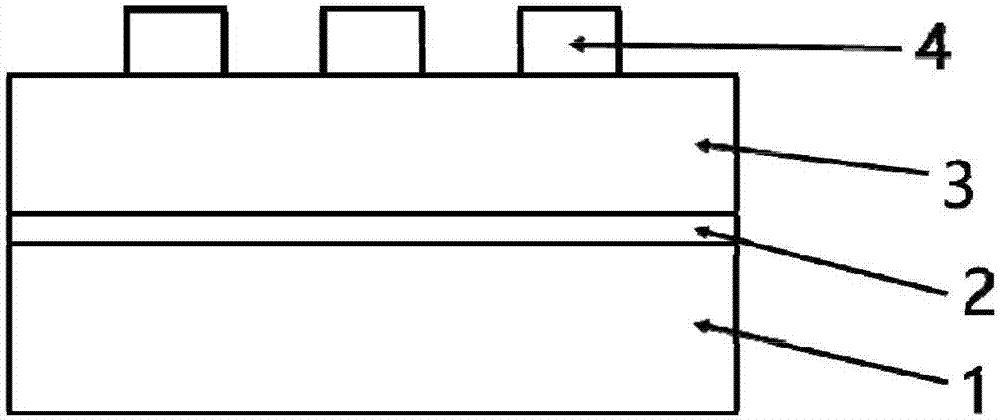

[0048] The first embodiment of the method for preparing an infrared absorber based on a dielectric micropillar array provided by the present invention includes the following steps:

[0049] S1 Select a single crystal silicon with a thickness of 1000 μm as the substrate, first use acetone solution to ultrasonically clean the single crystal silicon for 3 minutes; then use an anhydrous ethanol solution to ultrasonically clean the single crystal silicon for 3 minutes; The crystalline silicon is ultrasonically cleaned for 2 minutes, and the gold powder is vaporized and condensed by electron beam evaporation equipment, thereby forming a 200nm gold-plated layer on the surface of the substrate and obtaining the first intermediate product.

[0050] S2 growing a silicon dioxide layer with a thickness of 1030 nm on the surface of the gold-plated layer of the first intermediate product by using a magnetron sputtering device to obtain a second intermediate product.

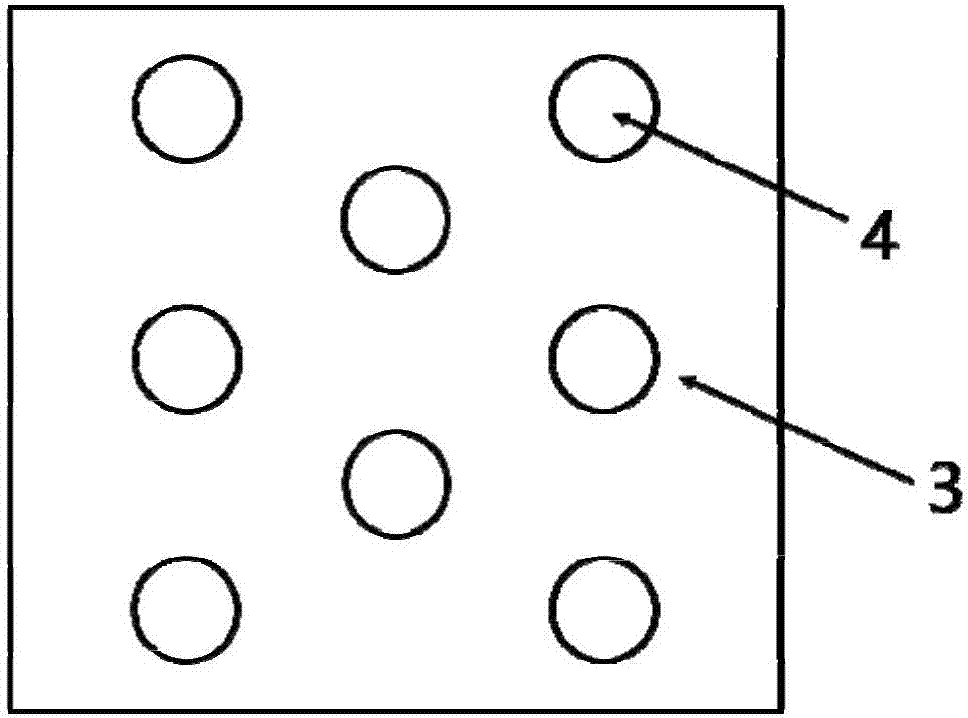

[0051] S3 On the silic...

no. 2 example

[0055] Second embodiment: Step S2 The thickness of the silicon dioxide layer is 1290 nm. In step S3, the diameter of the pillars in the dielectric micropillar array is 1100 nm, the height of the pillars is 680 nm, and the distance between the centers of two adjacent pillars is 2000 nm. The silicon grown in step S4 with a thickness of 680 nm.

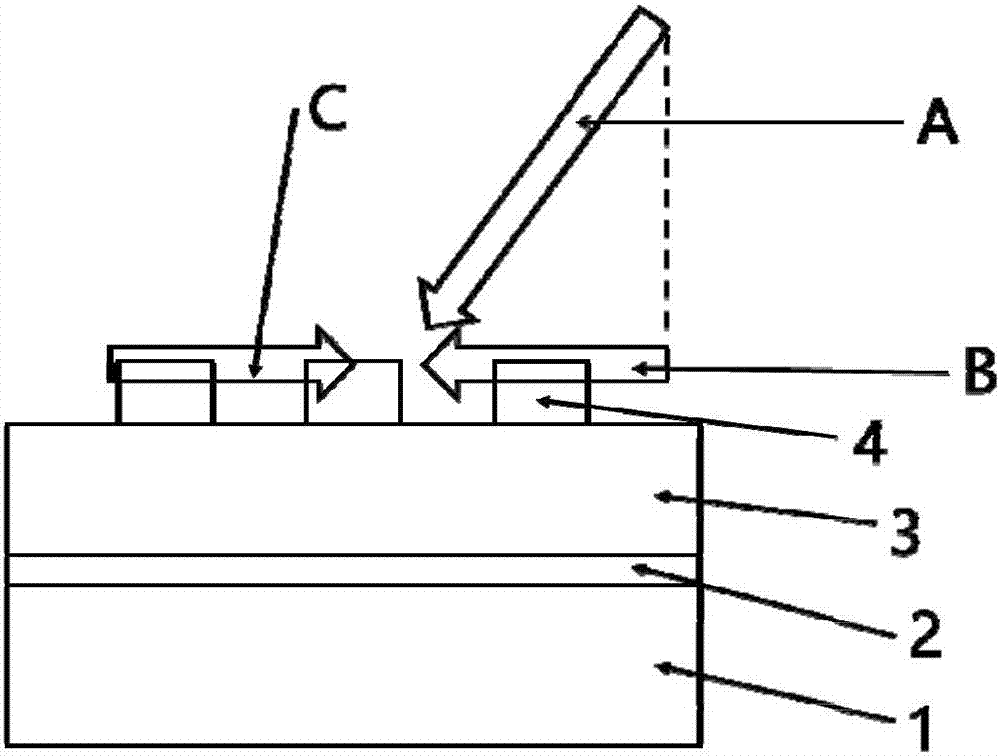

[0056] Figure 5 For the infrared absorption spectrum of the infrared absorber finally obtained in the second embodiment provided by the present invention, when the laser incident angle is 0°, the wavelength of the absorption peak of the infrared absorption spectrum is located at 3.27 microns, and the absorption bandwidth is about 10.9 Nanometer, the figure of merit is about 300.

no. 3 example

[0057] Embodiment 3: Step S2 The thickness of the silicon dioxide layer is 1690 nm. In step S3, the diameter of the pillars in the dielectric micropillar array is 1430 nm, the height of the pillars is 890 nm, and the distance between the centers of two adjacent pillars is 2640 nm. The silicon grown in step S4 has a thickness of 890 nm.

[0058] Figure 6 For the infrared light absorption spectrum of the infrared absorber finally obtained in the third embodiment provided by the present invention, when the laser incident angle is 0°, the wavelength of the absorption peak of the infrared absorber is located at 4.26 microns, and the absorption bandwidth is about 21.3 Nanometer, quality factor is about 200.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com