Test wiring wire clamp

A technology for testing wiring and clamps, which is applied in the direction of instruments, measuring devices, and parts of electrical measuring instruments. It can solve problems such as poor contact, unsatisfactory work requirements, and many test clamps, so as to ensure standardization and normalization. Improving the efficiency of on-site operations and improving the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0028] Embodiment 2 of the present invention differs from Embodiment 1 only in that an insulating protective cover is provided on the outside of the handle of the first wire clip, the outside of the handle of the second wire clip and the outside of the shared handle to prevent the user from Electric shock during use improves the safety factor of users.

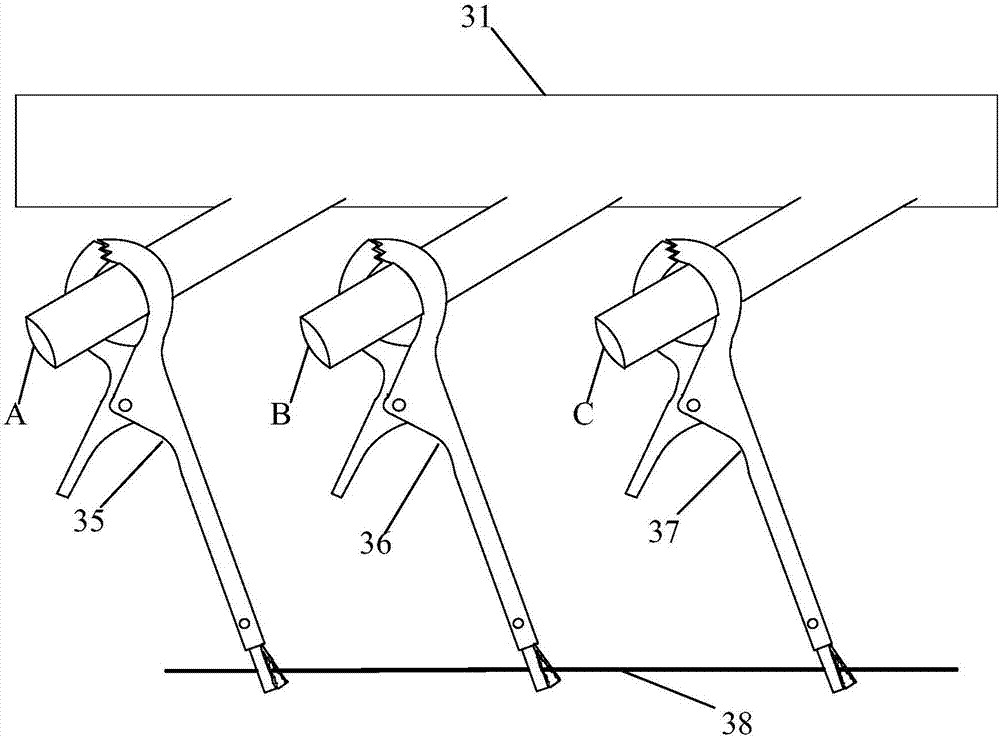

[0029] Embodiment 3 of the present invention, as image 3 As shown, the specific usage scenarios of the test wiring clip are provided.

[0030] Concretely, prepare the test wiring clamp 35, the test wiring clamp 36 and the test wiring clamp 37, the first clamps of the three test wiring clamps are all battery clips, and the second clamps are all button type alligator clips. The dimensions of the three test wiring clips are: length 130mm, width 50mm, height 10mm; the maximum opening size of the battery clip is 20mm, and the bite depth is 25mm; the maximum opening size of the button-type crocodile clip is 10mm, The depth of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com