Automatic energy storing high-pressure liquid injecting CO2 phase change pulse coal and rock body cracking method

A coal-rock mass and high-pressure liquid storage technology, which is applied in the field of CO2 phase change solid fracturing, can solve the problems of small fracturing range, inability to achieve continuous action, and low fracturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

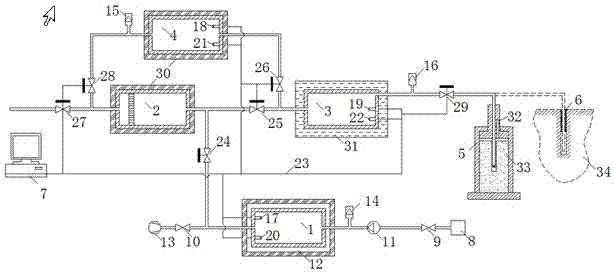

Method used

Image

Examples

Embodiment 1

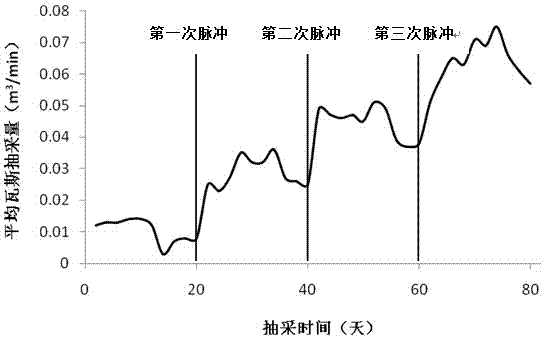

[0040] (1) Drilling. A group of parallel boreholes were constructed along the vertical coal wall of the 15116 working face of a mine, a total of 11 holes, numbered 1 from left to right # ~11 # , the drilling diameter is 75mm, the hole depth is 30m, and the drilling spacing is 3m. 6 in the very center # The drilled holes are pre-splitting holes, and the remaining drilled holes are drainage holes. Immediately after the completion of the drilling construction, the drainage hole was sealed and extracted at a depth of 10.5m. After 20 days of negative pressure extraction, the first pulse fracturing test was carried out.

[0041] (2) vacuuming. Send the outlet end of the pipeline to a depth of 20m in the fracturing hole and seal the hole. Open stop valve 10, start vacuum pump 13, carry out degassing, record the pressure of vacuum gauge on the vacuum pump, when pressure value does not change, stop degassing, close stop valve 10.

[0042] (3) Liquid supply. Open the shut-off val...

Embodiment 2

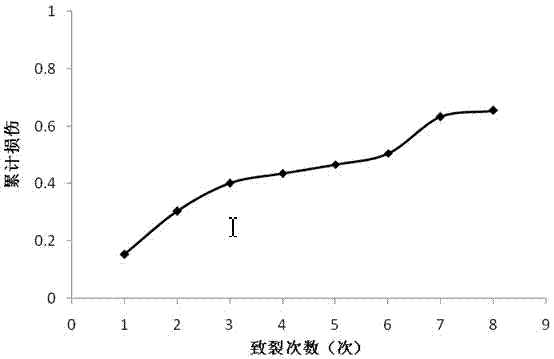

[0050] (1) Prepare the sample. After fully mixing cement, sand, gypsum, and water in a mixer in a mass ratio of 8:20:1:4, make a sample of 1000mm×1000mm×800mm, and use a small vibrating rod to vibrate and tamp during the production process. Artificial maintenance for 21 days. The universal coefficient f of the sample is 3.4, and a cracking hole with a diameter Φ of 50 mm and a depth d of 500 mm is reserved in the sample.

[0051] (2) Seal the hole. Send the outlet end of the pipeline to a depth of 400mm in the fracturing hole, and use PD composite material to seal the hole with a sealing depth of 300mm.

[0052] (3) Ultrasonic speed measurement. Use an ultrasonic flaw detector to measure the ultrasonic wave velocity with the horizontal and vertical lines in the center of the borehole as the reference line, and measure the ultrasonic wave velocity at a measuring point with an interval of 50 mm up, down, and left and right. During the measurement, butter is used as the coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com