Refuse landfill leachate guide and drainage pipe dredging device

A technology for landfill and leachate, applied in water supply installations, cleaning sewer pipes, waterway systems, etc., can solve the problems of easy residues of small substances, pollution of surrounding residents' domestic water, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

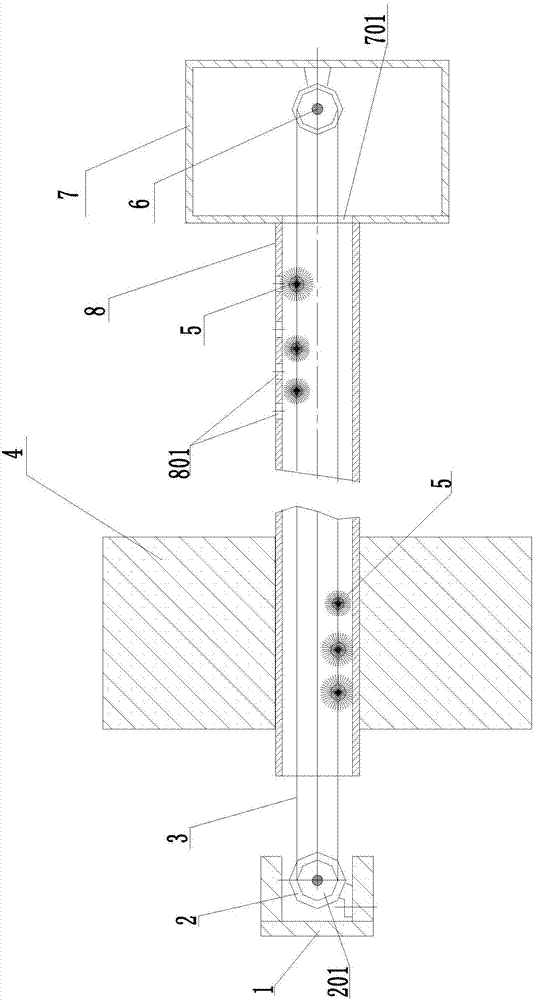

[0017] Such as figure 1 As shown, a device for dredging a landfill leachate drainage pipe according to the present invention includes a fixed frame 1, a traction rope 3 and a leachate drainage pipe 8; the leachate drainage pipe 8 is fixedly arranged on the dam body 4; the fixed frame 1 is arranged in the direction of one nozzle of the leachate drainage pipe 8; a fixed pulley is arranged in the direction of the other nozzle of the leachate drainage pipe 8 6; the inside of the fixed frame 1 is fixed with a hoist 2; the fixed frame 1 is arranged outside the dam body 4 for easy maintenance; the reel on the hoist 2 is a driving drum 201; one end of the traction rope 3 is connected to the On the driving drum 201; the other end of the traction rope 3 passes through the leachate drain pipe 8 and is connected to the fixed pulley 6; several steel wool balls 5 are fixed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com