Clogging preventing method for drainage channel based on underground high-flow-capacity drainage system

A drainage channel and drainage system technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems that cannot meet the actual requirements of the total project, complex technical requirements, restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific implementation examples

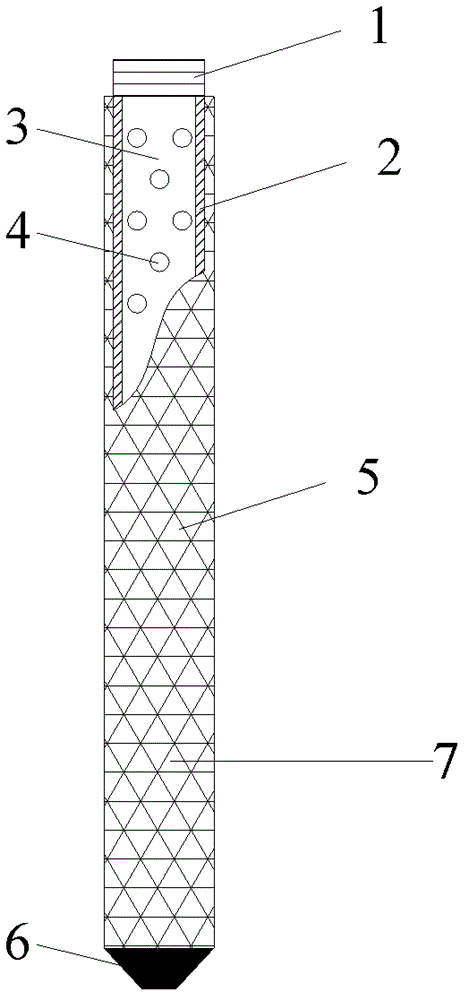

[0031] figure 1 It is the front view and section view of the one-way vertical large water discharge body, figure 2 yes figure 1 top view of image 3 Front view and sectional view of vertical drainage body with horizontal drainage channels; Figure 4 yes image 3 top view; see Figure 1-4 As shown, the drainage channel anti-silting method based on the large underground water flow drainage body, wherein the mentioned underground large water flow drainage body includes a vertical drainage body skeleton 2, and the skeleton material of the drainage body can be selected from iron, steel or plastic ( Such as PVC, PE or HDPE), and the filter cloth or filter membrane with a certain equivalent pore size is attached to the skeleton of the drainage body by artificial binding or hot-melt molding to form a vertical one-way large-flow drainage body 7, Connect the flexible permeable pipe 19 to the upper interface 1 of the vertical drainage bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com