Movable suspension type eddy-eliminating beam system for eliminating vertical-axis eddy at water inlet

A water inlet and suspension technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve the problems of narrow vertical axis vortex range and small range of adaptable water head, to avoid irregular vibration, adapt to a wide range of water head, eliminate Effects of operational safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

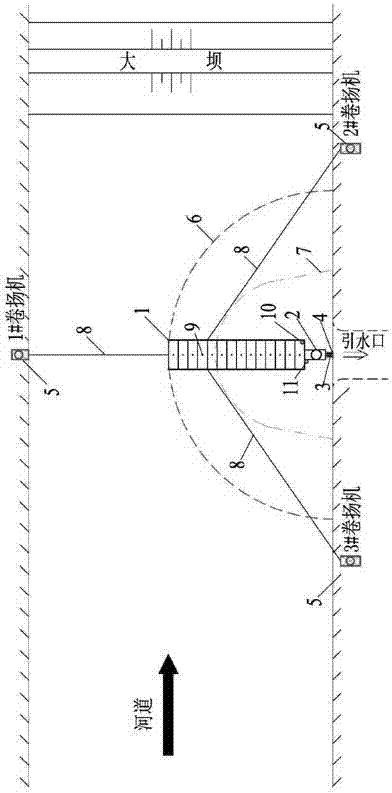

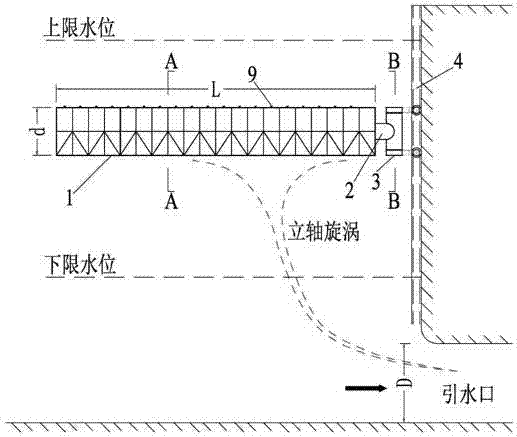

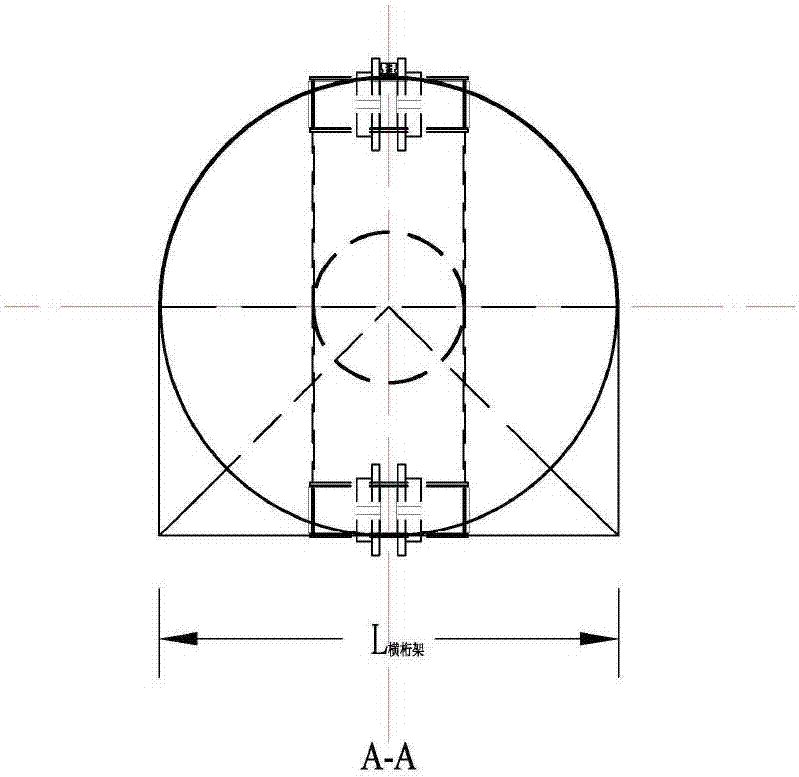

[0066] This embodiment is used to eliminate the movable suspension vortex elimination beam system of the vertical axis vortex of the water inlet, and its structure is as attached figure 1 , attached figure 2 , attached Figure 3-1 And attached Figure 3-2 As shown, its structure includes a single vertical guide rail 4 fixedly arranged on the wall of the hole face above the water inlet, a sliding trolley 3 that can slide up and down along the vertical guide rail, a vortex elimination beam 1 suspended on the water surface for eliminating the vortex of the vertical shaft, and a water inlet The 3# winch 5 on the upstream side of the bank, the 2# winch on the downstream side of the water inlet and the 1# winch on the opposite bank of the water inlet are set. On the trolley, the steel cable 8 on the hoist set on the upstream and downstream sides of the water inlet is connected to the traction point on the outer side of the vortex elimination beam in the middle, so as to control a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com