Preparation process of polycarbonate

A polycarbonate, preparation technology, applied in the field of chemical production, can solve environmental problems such as pollution, resource waste, etc., and achieve the effects of accelerating rupture, reducing pollution, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

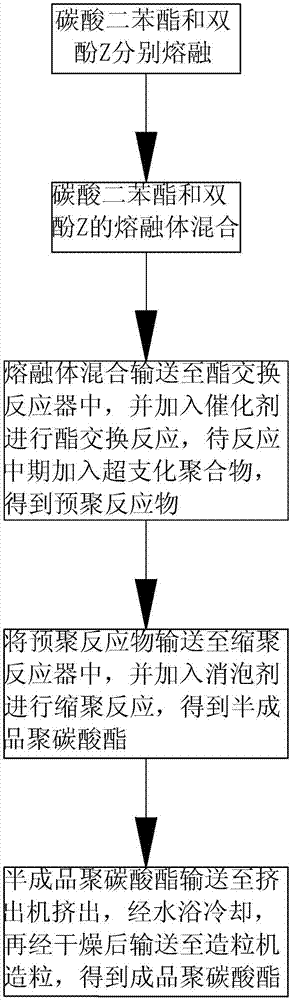

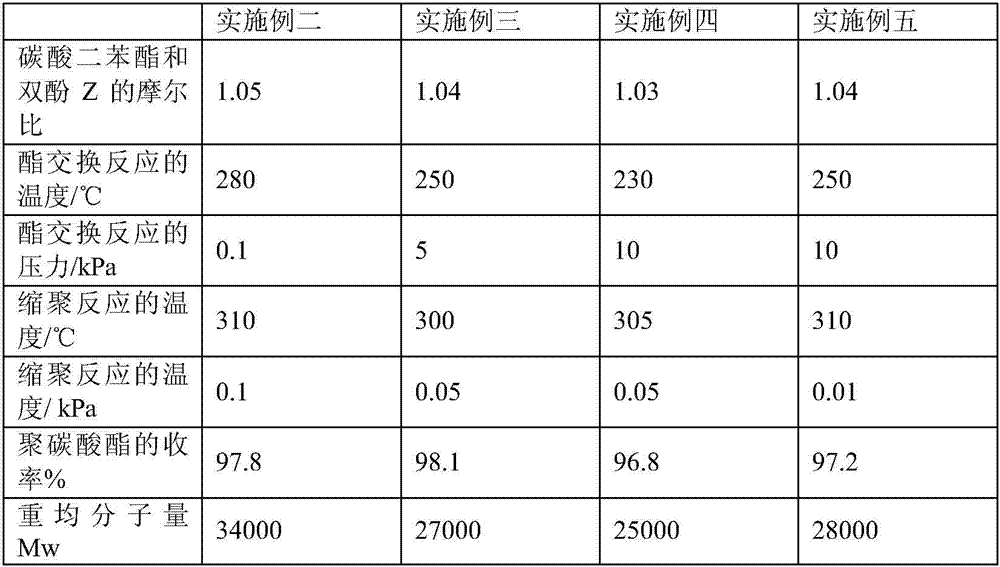

[0037] Step 1: Put diphenyl carbonate and bisphenol Z in a molar ratio of 1.03, and put them into two melting tanks to heat up and completely melt;

[0038] Step 2: transport the melt of diphenyl carbonate and bisphenol Z to the same mixing tank for stirring and mixing, the stirring speed is 800rpm, and the stirring time is 10min;

[0039] Step 3: transport the mixture in the mixing tank to a transesterification reactor with a separation tower and a vacuum pump at one time, and add a catalyst to carry out transesterification reaction, and add hyperbranched polymer when the reaction is in the middle, and the total reaction time is 1 hour. The prepolymerized reactant, wherein the temperature during the transesterification reaction is 210°C, and the pressure is 10kPa;

[0040] Step 4: Transport the prepolymerized reactant to a polycondensation reactor with a condenser and a vacuum pump, and put in a defoamer to carry out a polycondensation reaction. The total reaction time is 2 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com