Method and device for preparing hydrogel microspheres

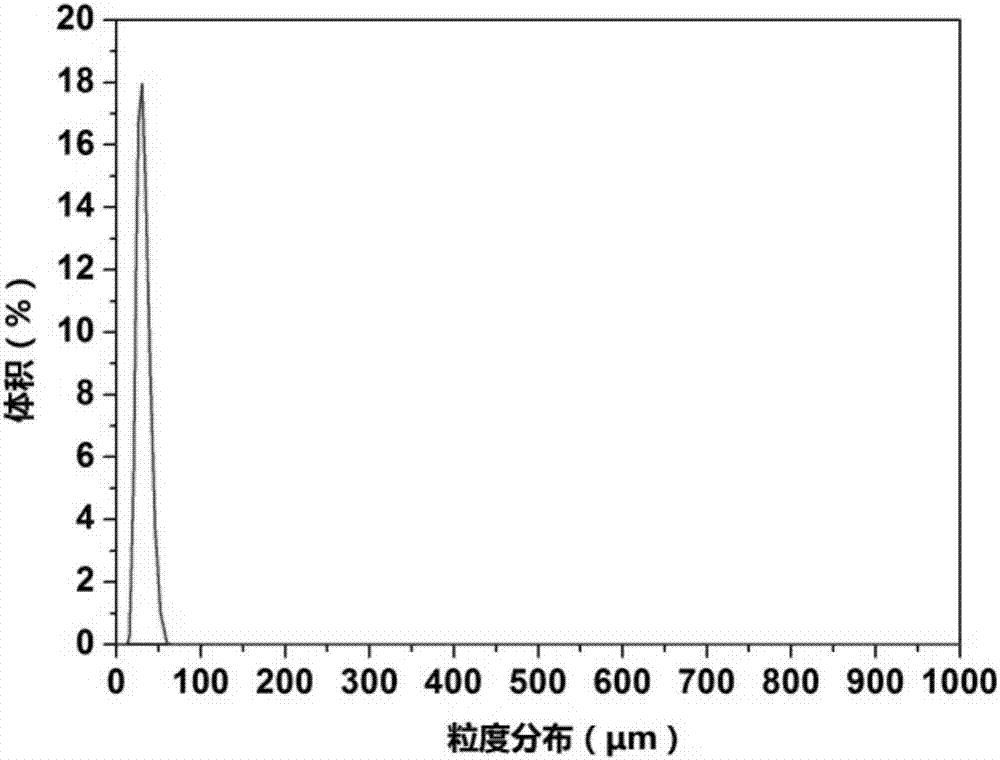

A technology of hydrogel microspheres and water-in-oil, which is applied to chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of large particle size distribution range and poor repeatability, and achieve a reliable particle size. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

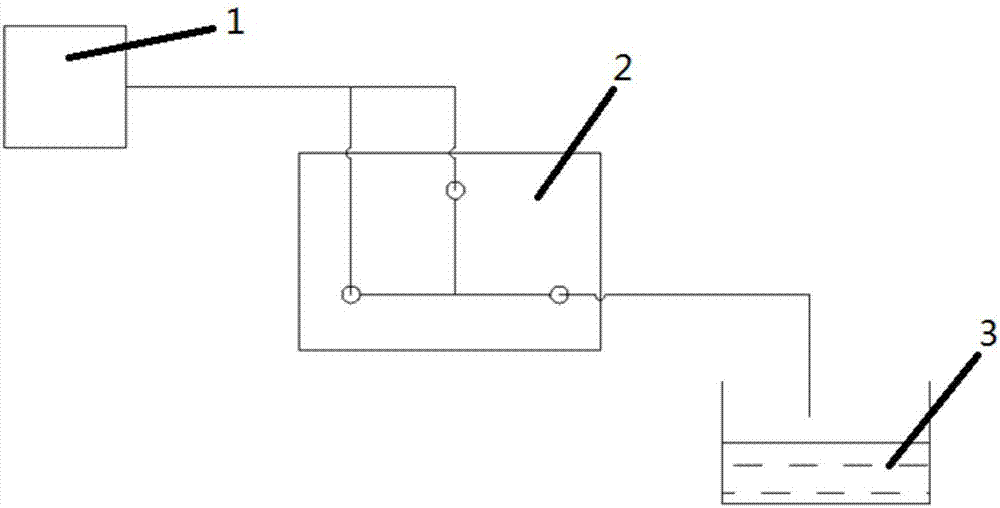

Method used

Image

Examples

Embodiment 1

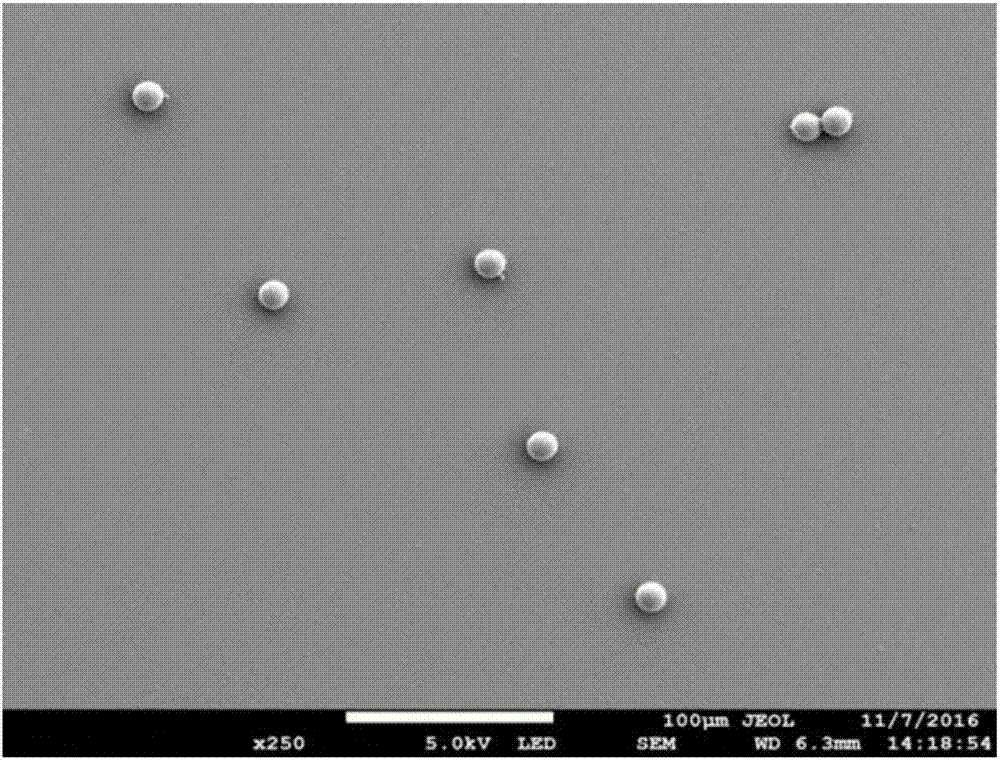

[0019] In this example, acrylamide monomer is used as a water-soluble monomer, methylenebisacrylamide is used as a crosslinking agent, VA-086 is used as an initiator, and water is used as a pore-forming agent to prepare hydrogel microspheres with a swelling degree of 6 times.

[0020] Concrete preparation steps are as follows:

[0021] (1) Preparation of aqueous mixture: Weigh acrylamide monomer (0.6g), methylenebisacrylamide (0.036g) and VA-086 (0.012g) into a 5mL centrifuge tube, and measure 2.5mL 2mM The above mixture was dissolved in EDTA aqueous solution, mixed by vortex mixer, and ultrasonically dissolved, and the volume was adjusted to 4 mL to obtain an aqueous mixture.

[0022] The aqueous mixture was transferred to a vial with a silicone stopper inserted into a nitrogen-displaced needle. Nitrogen gas was slowly introduced to remove oxygen for 20 minutes. After the nitrogen replacement was completed, 300 μL of mineral oil was added.

[0023] (2) Preparation of oily ...

Embodiment 2

[0028] In this example, carboxyacrylamide monomers were used as water-soluble monomers to prepare hydrogel microspheres. The composition of the raw materials is shown in Table 1 below, and the preparation steps are the same as those in Example 1, so they will not be described again.

[0029] Table 1 Embodiment 2 raw materials and consumption table

[0030] Component Dosage Water-soluble monomer: acrylic acid 0.84mL Water-soluble monomer: acrylamide 0.36g Neutralizer: 20% sodium hydroxide solution 1.75mL Cross-linking agent: methylene bisacrylamide 0.012g Initiator: potassium persulfate 0.02g mineral oil Same as Example 1 Surfactant: Abil EM90 Same as Example 1 Pore former: water Dilute to 4mL

Embodiment 3

[0032] In this example, hydrogel microspheres were prepared by using methylol acrylamide monomer as a water-soluble monomer. The composition of the raw materials is shown in Table 1 below. The collected micro-droplets were cured at 70° C. for 12 hours. The other preparation steps were the same as those in Example 1, so they will not be repeated here.

[0033] Table 2 Embodiment 3 raw materials and consumption table

[0034]

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com