Novel thermal-activated-delayed-fluorescence luminescent material and application thereof

A technology of thermally activated delay, luminescent materials, applied in luminescent materials, electrical components, circuits, etc., can solve the problems of device efficiency roll-off, low device fluorescence lifetime, lack of red light TADF molecules, etc., to achieve high glass transition temperature, The effect of good luminous properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

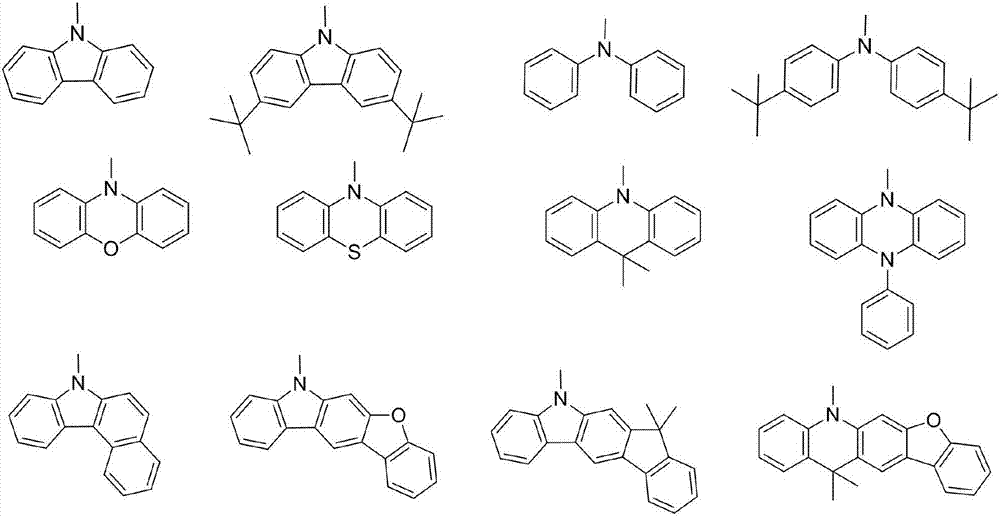

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the preparation of intermediate M1

[0035]

[0036] Introduce 4-bromopyridine (15.8g, 0.1mol) and dry tetrahydrofuran (79g) into a 250mL Erlenmeyer flask, stir to dissolve, and set aside.

[0037] Under the condition of nitrogen protection, 5 mL of the above prepared tetrahydrofuran solution of 4-bromopyridine was introduced into a 250 mL three-necked flask. The bath temperature was set at 65°C, the temperature was raised with stirring, and 2 grains of iodine were introduced to initiate the reaction. After initiation, start to drop the remaining 4-bromopyridine in tetrahydrofuran solution, control the dropping speed, and keep the internal temperature below 65°C. After the dropwise addition was completed, the reaction was incubated for 2 hours. After the heat preservation was completed, a solution of 2,5-dibromo-3,6-dimethylterephthalaldehyde (16.0 g, 0.05 mol) in tetrahydrofuran (32 mL) was added dropwise. After the dropwise addition, the stirring w...

Embodiment 2

[0041] Embodiment 2: the preparation of intermediate M2

[0042]

[0043] Using a method similar to Example 1, using an equivalent amount of 2-bromopyridine instead of 4-bromopyridine, and other conditions unchanged, the intermediate M2 was obtained, 7.2 g of white crystals, with a yield of 75.9%.

[0044] Mass spectrum MS (m / e), molecular formula C 20 h 14 Br 2 N 2 o 2 , the theoretical value is 473.9, and the test value is 474.8.

[0045] Elemental analysis (C 20 h 14 Br 2 N 2 o 2 ), theoretical value: C, 50.66%; H, 2.98%; Br, 33.70%; N, 5.91%; O, 6.75%; measured value: C, 50.65%; 5.91%; O, 6.73%.

Embodiment 3

[0046] Embodiment 3: the preparation of intermediate M3

[0047]

[0048] Using a method similar to Example 1, using an equivalent amount of 2,5-dibromo-3,6-diisopropyl terephthalaldehyde to replace 2,5-dibromo-3,6-dimethyl-p-phthalaldehyde Diformaldehyde, other conditions remain unchanged, to obtain intermediate M3, white crystal 8.7g, yield 82%.

[0049] Mass spectrum MS (m / e), molecular formula C 24 h 22 Br 2 N 2 o 2 , the theoretical value is 528.0, and the test value is 529.1.

[0050] Elemental analysis (C 24 h 22 Br 2 N 2 o 2 ), theoretical value C, 54.36%; H, 4.18%; Br, 30.14%; N, 5.28%; O, 6.03%; measured value C, 54.35%; H, 4.20%; ; O, 6.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum brightness | aaaaa | aaaaa |

| Maximum current efficiency | aaaaa | aaaaa |

| Maximum power efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com