Flexibility pneumatic elevation-type transfer machine and using method thereof

A pneumatic lifting and flexible technology, applied in the direction of cranes, etc., can solve the problem of small lifting coverage area, and achieve the effect of expanding the lifting coverage area, expanding the lifting coverage area, and flexible lifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

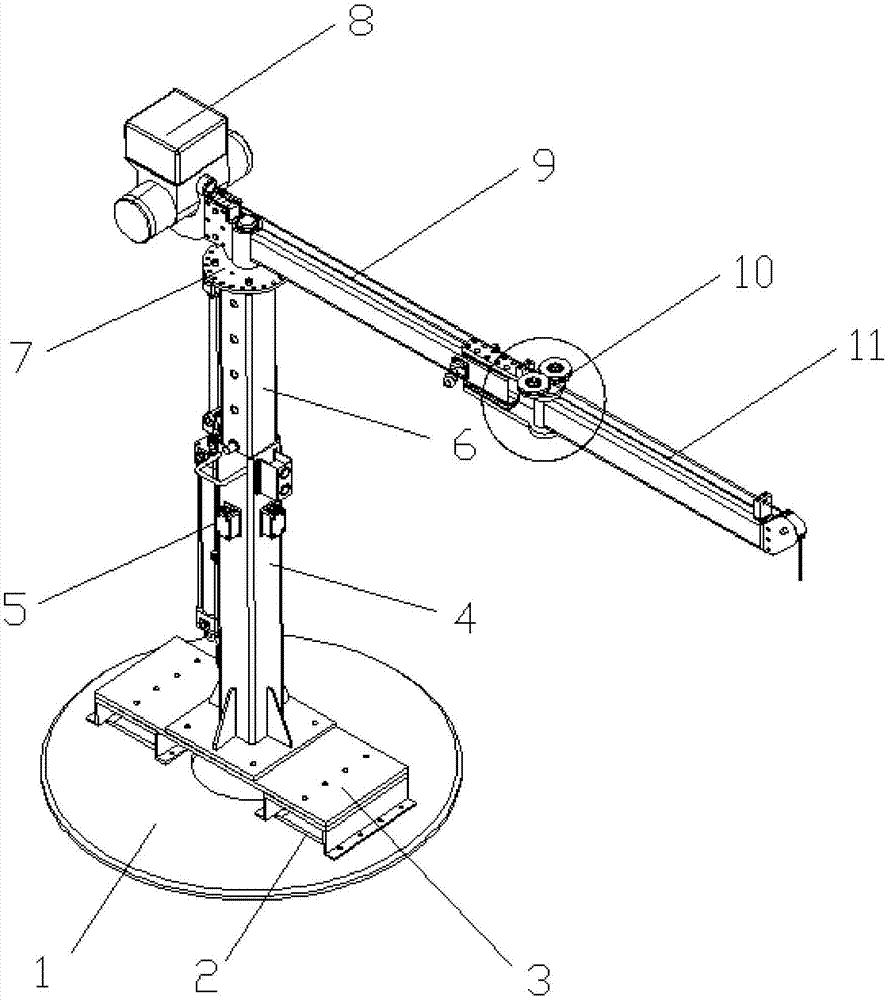

[0041] Such as figure 1 As shown, a flexible pneumatic lifting transfer machine includes a base 1, a column and a cantilever. The base 1 is a disc-shaped structure, which can increase the contact area with the ground and prevent the equipment from moving when transporting materials. There is a risk of rollover; the base 1 is provided with a moving cart hole 2 and a forklift hole 3 to realize the function of moving at any time, and at the same time realize the function of lifting the equipment to walk, and dropping it to use, which is convenient and fast;

[0042] The column is fixed on the base 1; the column includes a column fixed part 4 and a column movable part 6; the column fixed part 4 is fixedly connected to the base 1; the column The movable part 6 is arranged inside the column fixing part 4;

[0043] In order to further improve automation, this embodiment also includes a cylinder; the cylinder body of the cylinder is fixedly connected to the outer wall of the column f...

Embodiment 2

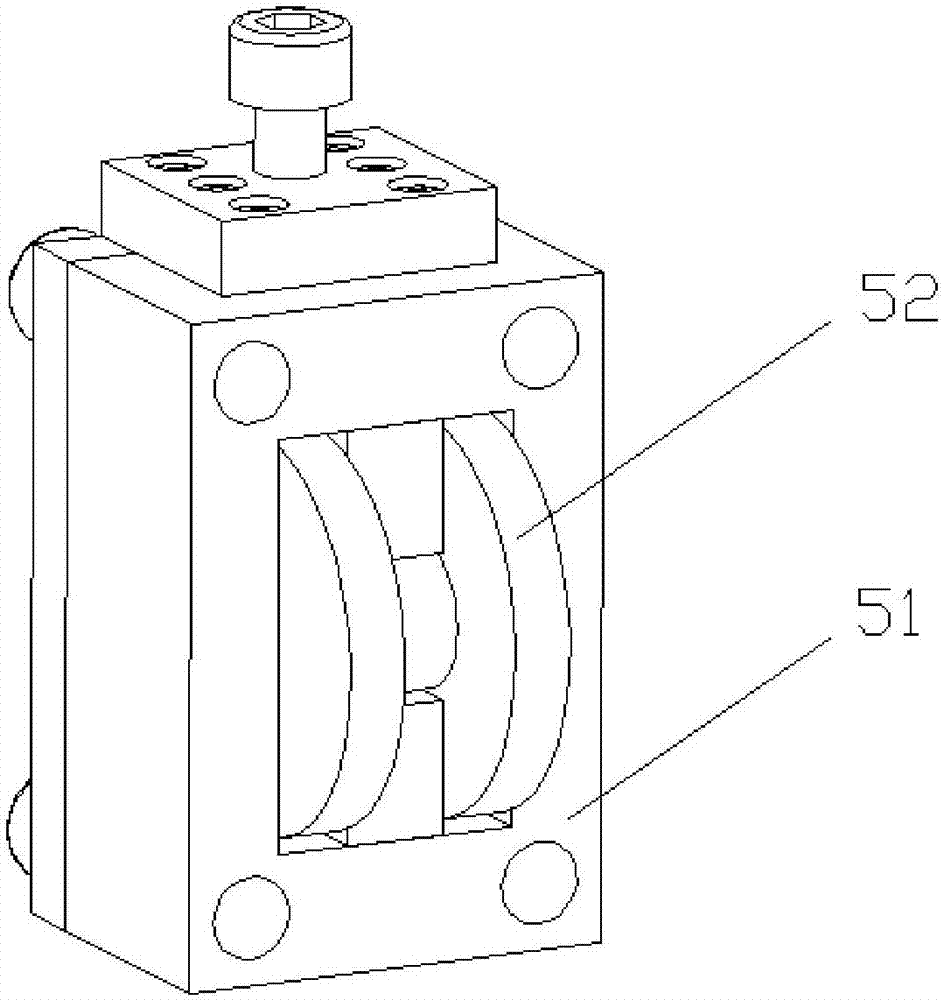

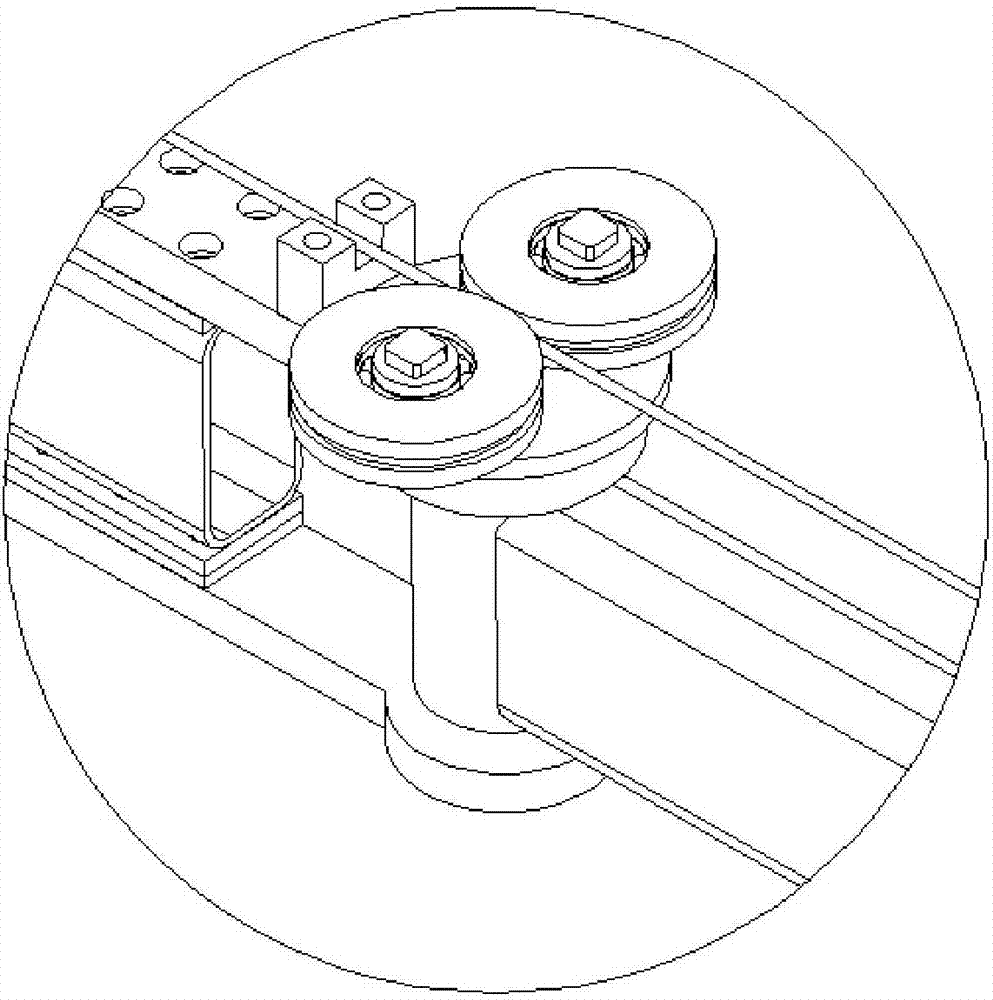

[0059] A flexible pneumatic lifting transfer machine is basically the same as Embodiment 1, the difference is that a guide pulley 5 is arranged between the column fixed part 4 and the column movable part 6; the guide pulley 5 The structure is as figure 2 As shown, it includes a casing 51 and a roller 52 arranged in the casing 51; as figure 1 As shown, the shell 51 is fixed on the outer wall of the column fixing part 4, and an opening is arranged on the outer wall of the column fixing part 4, so that the roller 52 passes through the opening and the column movable part 6 The inner wall contact; the guide pulley 5 can make the movable part of the column 6 go up and down more smoothly, and the stagnation phenomenon will not occur with the fixed part of the column, and the lifting is more flexible.

Embodiment 3

[0061] A flexible pneumatic lifting transfer machine, which is basically the same as Embodiment 1, the difference is that a turntable 7 is provided at the rotatable connection between the cantilever and the column; the turntable 7 is provided with an angle Limiting block; the turntable 7 is pre-set with a plurality of evenly distributed mounting holes along the circumferential direction, and the angle limiting block adjusts the relative position between the cantilever and the column through screws and the mounting holes to achieve different angles limit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com