Supporting roll device dragged by superconductive outer rotor electric machine

A technology for external rotor motors and back-up rolls, which is applied in the direction of counter pressure devices, metal processing equipment, metal rolling, etc., and can solve problems such as increased difficulty in spatial arrangement of rolling mills or straightening machines, increased maintenance costs, and deformation of back-up rolls. Achieve the effect of facilitating industrial application and solving the difference in temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below through preferred embodiments in conjunction with the accompanying drawings.

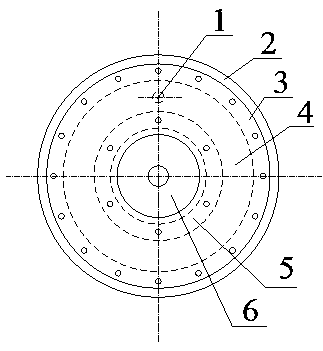

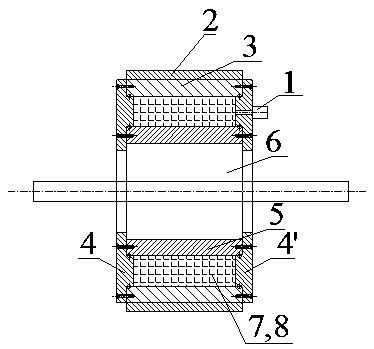

[0015] Arrange the device of the present invention in a staggered manner on the upper and lower work rolls of the strip, replace the staggered backup rolls in the prior art, and support them in a staggered manner; as figure 1 As shown, the outer cylinder 3, the left and right annular end caps 4, 4' and the inner cylinder 5 are assembled into an annular cavity 8, and the 3D printing space support structure 7 is loaded into the annular cavity 8, and the 3D printing space support 7 It is a space truss structure printed by a 3D printer to ensure a reasonable supporting effect. The annular cavity 8 is evacuated through the vacuum check valve 1 to achieve a heat-resistant vacuum environment. A superconducting outer rotor motor stator and outer rotor form a superconducting The magnetic levitation structure, by controlling the stator current of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com