Self-sealing door device of model line end milling shield

A technology of automatic closure and protective cover, which is applied in the direction of milling machine equipment, milling machine equipment details, maintenance and safety accessories, etc., can solve the problems of increasing the labor burden of operators, heavy weight, hitting people, etc., to reduce manpower output and design Reasonable and simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

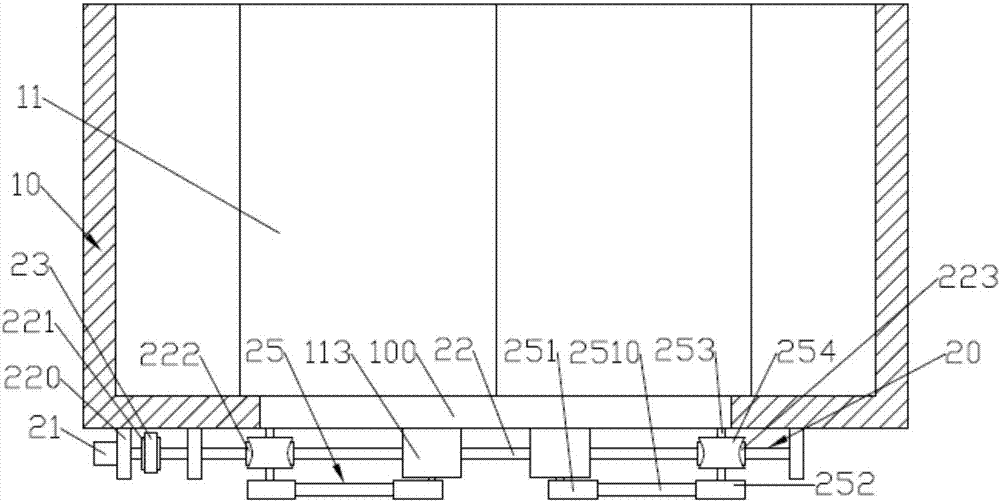

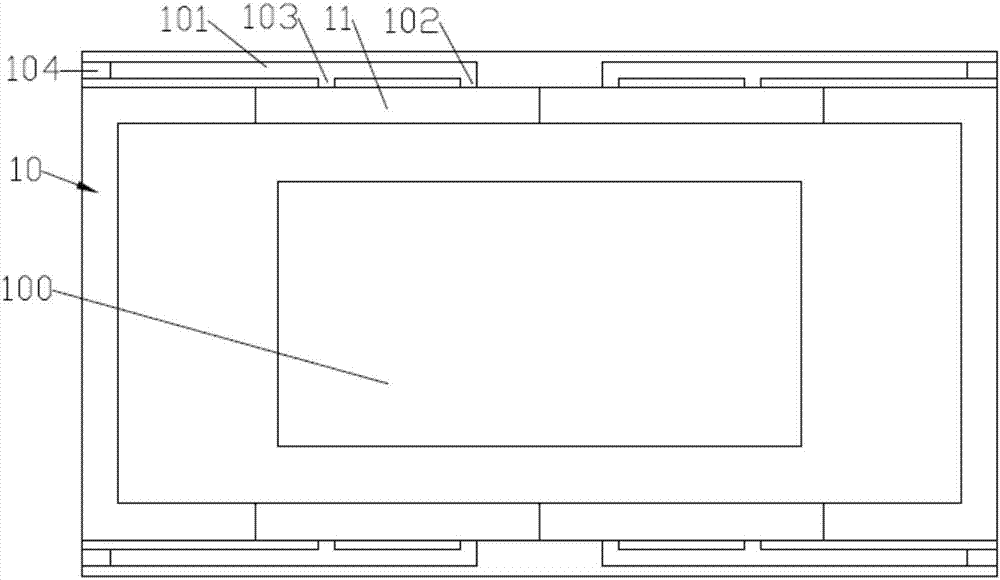

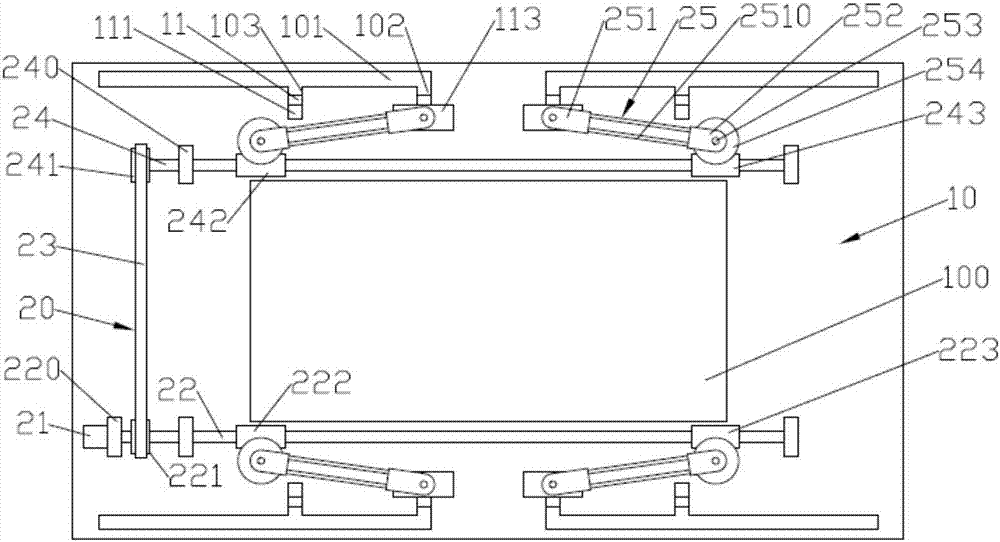

[0021] Such as Figure 1 ~ Figure 3 As shown, an automatic closing door device for a model line end milling protective cover includes a protective cover body 10 and a closed door opening and closing device 20; the protective cover body 10 includes a rectangular frame and a bottom plate; A cuboid with a square through hole; the rectangular frame is vertically fixed at the center of the upper end of the base plate and the front and rear width of the base plate is greater than the front and rear width of the rectangular frame; the front and rear side walls of the rectangular frame are respectively provided with front and rear closed door installation holes; the closed door installation A pair of left and right symmetrical closed doors 11 are installed in the hole; the center of the bottom plate is provided with a square through groove 100; guide grooves; a pair of closed doors 11 on the same side are respectively slid and arranged in a pair of left and right symmetrical guide gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com