An automatic processing equipment for riser drilling and packaging

A processing equipment and drilling machine technology, applied in metal processing equipment, drilling/drilling equipment, packaging, etc., can solve problems such as slow processing efficiency and inconsistent drilling, and achieve high work efficiency, ensure consistency, and save energy. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

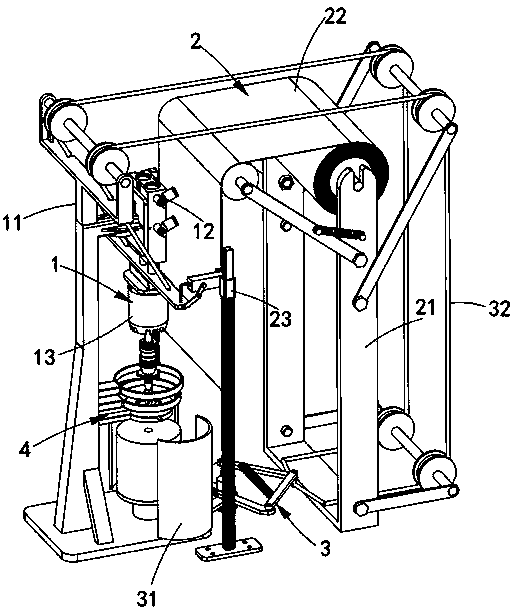

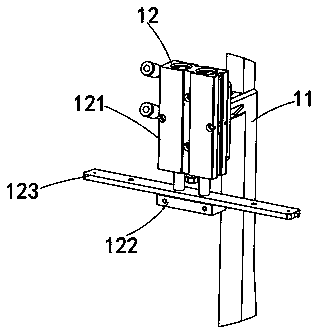

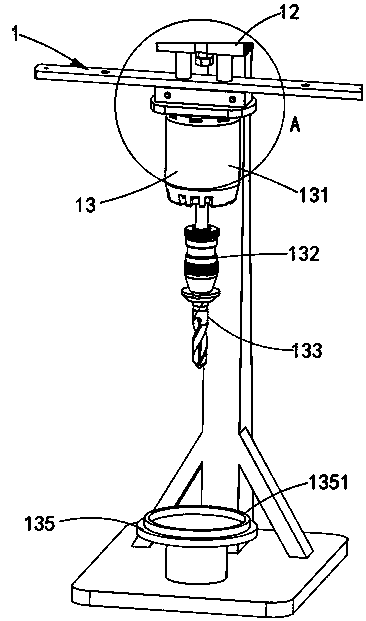

[0073] Such as figure 1 As shown, a riser drilling packaging automation processing equipment includes a drilling mechanism 1 and a sealing mechanism 3, the drilling mechanism 1 is arranged on the front side of the paper feeding mechanism 2, and it includes a drilling frame 11, The lifting assembly 12 and the drilling assembly 13, the lifting assembly 12 is fixedly arranged on the top of the drilling frame 11, and the lower end is connected with the drilling assembly 13;

[0074] The paper feeding mechanism 2 includes a paper feeding frame 21, a paper feeding assembly 22 and a symmetrically arranged paper clamping assembly 23. The paper feeding frame 21 is arranged on the rear side of the drilling frame 11, and the upper end thereof is provided with the The paper feeding assembly 22, the paper clamping assembly 23 is symmetrically arranged on both sides of the paper feeding assembly 22, and it is connected to the lifting assembly 12;

[0075] The sealing mechanism 3 includes a...

Embodiment 2

[0113] Figure 12 It is a structural schematic diagram of Embodiment 2 of a riser drilling packaging automatic processing equipment of the present invention; as Figure 12 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0114] Such as Figure 12 , Figure 13 and Figure 14 As shown, a riser drilling packaging automation processing equipment, the cutting mechanism 4 is arranged on the lower part of the drilling frame 11, which includes a cutting knife group 41 and a fixed assembly 42, the cutting knife group 41 is fixedly connected with the drilling frame 11 through the fixing assembly 42;

[0115] The drill bit 133 is also provided with a blade block 1331 , the blade b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com