Copper molybdenum separation flotation agent and copper molybdenum separation method

A flotation agent, copper-molybdenum technology, used in flotation, solid separation, wet separation, etc., can solve the problems of low recovery rate of molybdenum, poor separation effect of copper and molybdenum, etc., to improve the enrichment ratio of molybdenum and enhance the inhibition effect. , selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

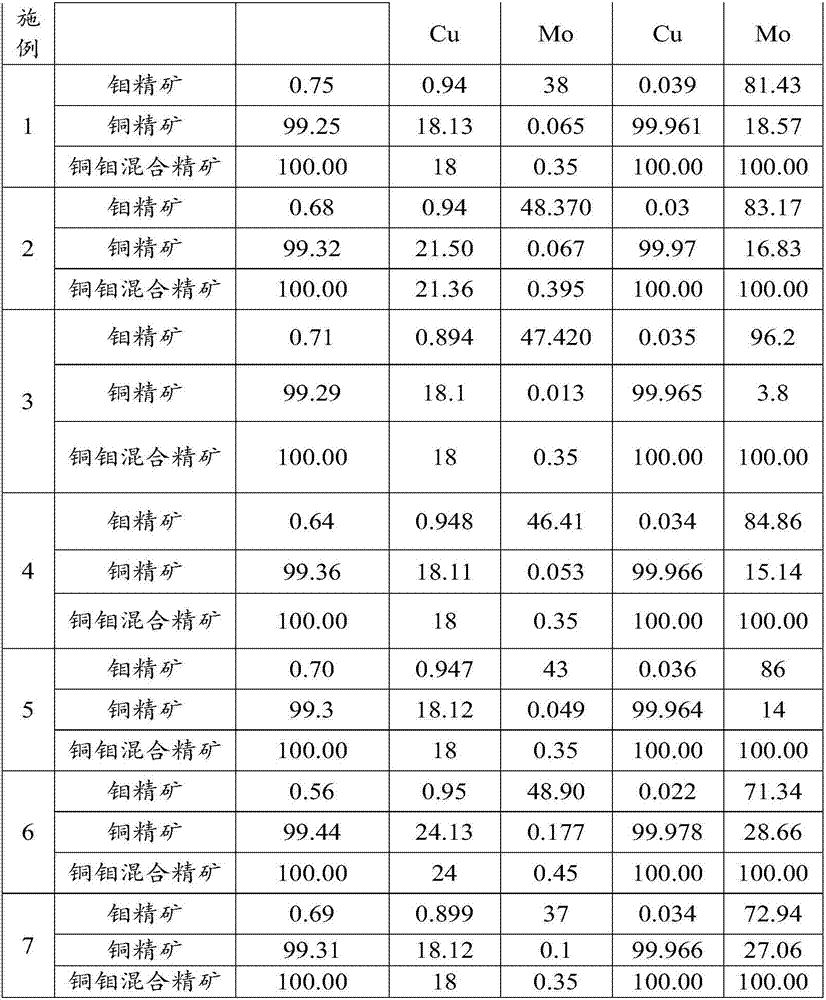

Embodiment 1

[0034] A copper-molybdenum separation flotation agent provided in this embodiment includes: 14kg sodium sulfide, 1300g sodium thioglycolate, 140g kerosene, and 2200g water glass.

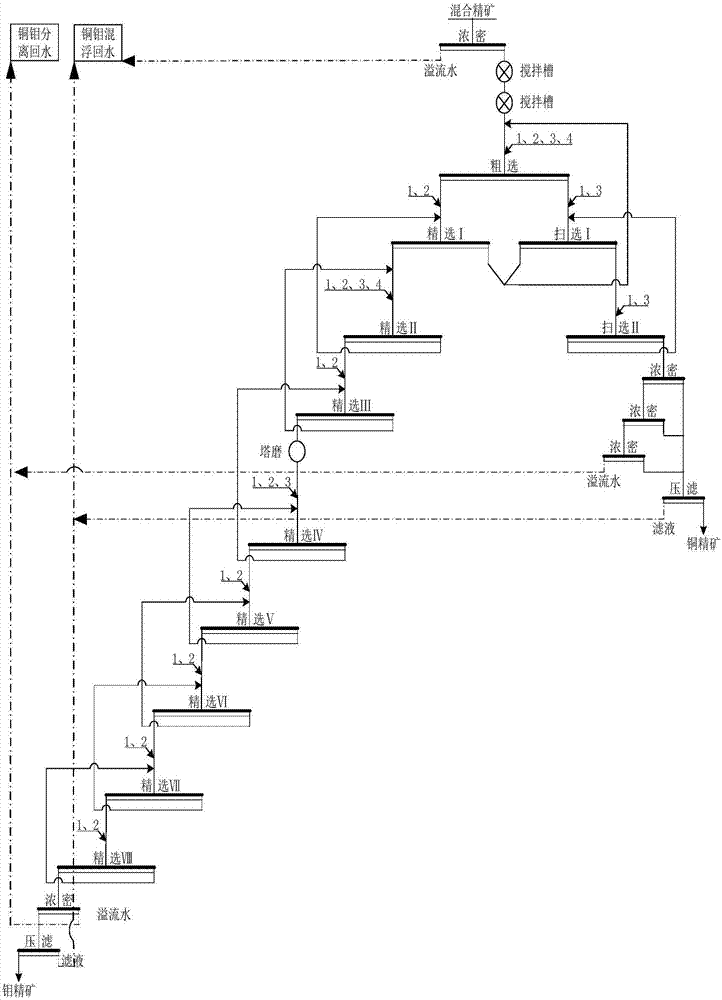

[0035] This embodiment provides a kind of figure 1 The method for copper-molybdenum separation shown, wherein, with 1 representative sodium sulfide, 2 representative sodium thioglycolate, 3 representative kerosene, 4 representative water glass.

[0036] The method of copper molybdenum separation is as follows:

[0037] 1 ton of raw ore containing copper minerals and molybdenum minerals is thickened to obtain copper-molybdenum mixed concentrate. In this embodiment, the given copper grade in the raw ore is 24%, and the molybdenum grade is 0.45%. The pulp concentration of the raw ore is 25%, and the concentration of the copper-molybdenum mixed concentrate after thickening treatment is 40%.

[0038] Stir the copper-molybdenum mixed concentrate in the mixing tank, then add the copper-molybdenum flotat...

Embodiment 2

[0052] The main difference between the copper-molybdenum separation flotation agent provided in this example and the copper-molybdenum separation flotation agent provided in Example 1 is that the copper-molybdenum separation flotation agent provided in this example includes: 13kg sodium sulfide, 1300g mercapto Sodium acetate, 130g kerosene, 1900g water glass.

[0053] A kind of method for separating copper and molybdenum provided in this embodiment, the main difference with the method for separating copper and molybdenum that embodiment 1 provides is:

[0054] The copper grade in the raw ore provided in this embodiment is 21.36%, and the molybdenum grade is 0.395%. The pulp concentration of the copper-molybdenum mixed concentrate is 30%, and the concentration of the copper-molybdenum mixed concentrate after thickening treatment is 50%. The total amount of copper-molybdenum flotation agent used in the whole process of copper-molybdenum separation of copper minerals and molybde...

Embodiment 3

[0056] The main difference between the copper-molybdenum separation flotation agent provided in this example and the copper-molybdenum separation flotation agent provided in Example 1 is that the copper-molybdenum separation flotation agent provided in this example includes: 12kg sodium sulfide, 1250g mercapto Sodium acetate, 120g kerosene, 1700g water glass.

[0057] A kind of method for separating copper and molybdenum provided in this embodiment, the main difference with the method for separating copper and molybdenum that embodiment 1 provides is:

[0058] Copper-molybdenum mixed concentrate is produced by thickening raw ore containing copper ore and molybdenum ore. The given head grade is 18% copper and 0.35% molybdenum. The slurry concentration of the copper-molybdenum mixed concentrate is 28%, and the concentration of the copper-molybdenum mixed concentrate after thickening treatment is 45%. The total amount of copper-molybdenum flotation agent used in the whole proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com