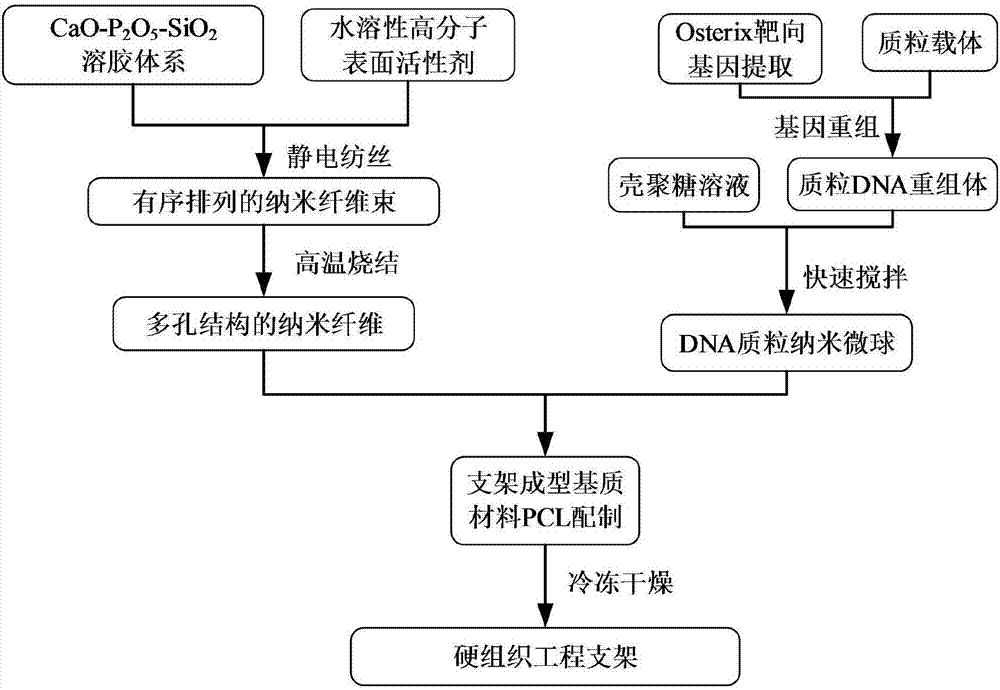

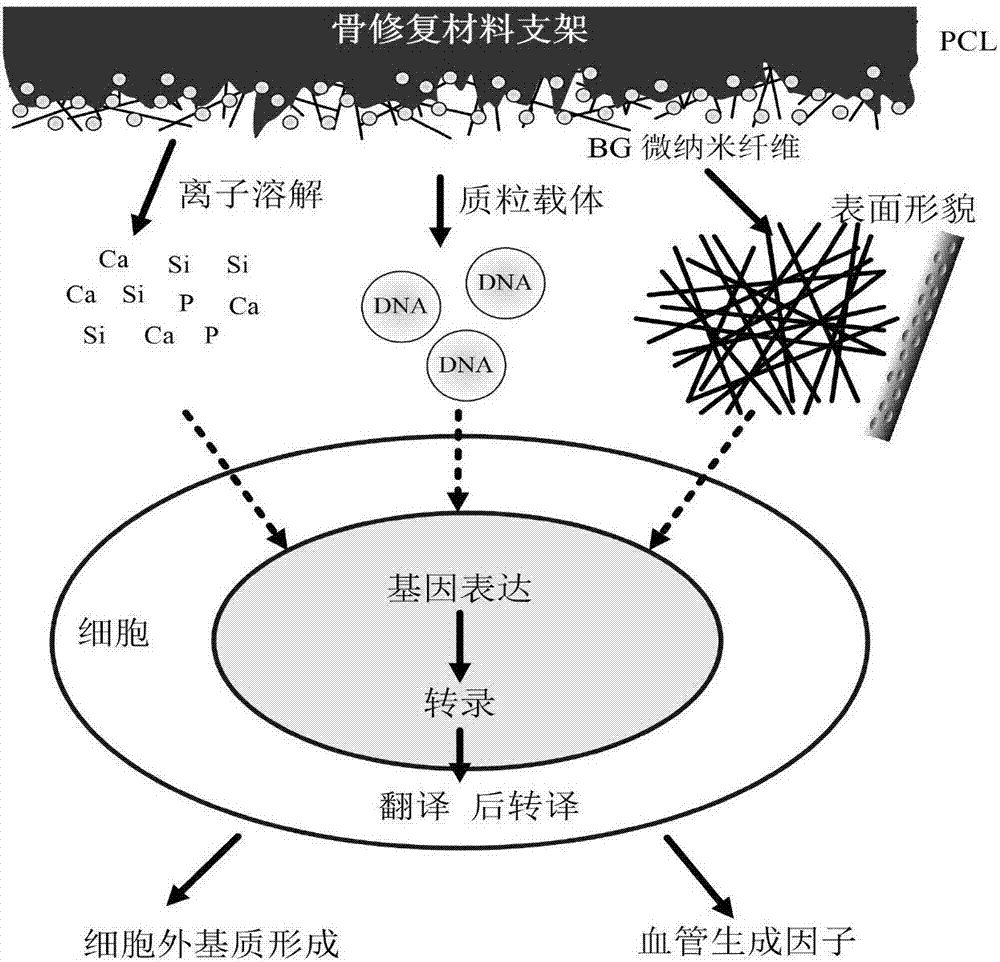

Preparation method of hard tissue engineering scaffold with gene regulation function

A gene regulation and hard tissue technology, applied in tissue regeneration, textiles and papermaking, medical science, etc., can solve the problems that it is difficult to meet the design requirements of scaffold materials, and the precise regulation of cell growth genes cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) in CaO-P 2 o 5 -SiO 2 P123 was added to the system, and the parameters of the electrospinning process were: electrostatic voltage 10Kv, receiving distance 10cm, spinning rate 1ml / h, relative humidity 25%. The high-speed rotating drum rotates at 200 rpm to obtain regularly arranged micro-nano fibers; the fibers are sintered at a temperature of 300 ° C for 120 minutes to make the surfactant on the fibers evaporate violently, thereby forming a pore structure on the surface of the fibers and obtaining mesoporous organisms Glass micro-nanofibers.

[0030] (2) Extract the Osterix target gene fragment, construct the target gene plasmid, and obtain the plasmid DNA recombinant by gene recombination technology. Mix the chitosan solution and plasmid DNA recombinant, the mixing mass ratio range is 2:1, utilize the attraction between chitosan molecules and DNA, form plasmid nano-microspheres under the condition of rapid stirring at 50 rpm .

[0031] (3) Mix the biological g...

Embodiment 2

[0033] (1) in CaO-P 2 o 5 -SiO 2P123 was added to the system, and the parameters of the electrospinning process were: electrostatic voltage 15Kv, acceptance distance 15cm, spinning rate 2ml / h, relative humidity 30%. The high-speed rotating drum rotates at 300rpm to obtain regularly arranged micro-nano fibers; the fibers are sintered at a temperature of 300°C for 120 minutes to make the surfactant on the fibers evaporate violently, thereby forming a pore structure on the surface of the fibers and obtaining mesoporous organisms Glass micro-nanofibers.

[0034] (2) Extract the Osterix target gene fragment, construct the target gene plasmid, and obtain the plasmid DNA recombinant by gene recombination technology. Mix the chitosan solution and plasmid DNA recombinant, the mixing mass ratio range is 3:1, utilize the attractive force between chitosan molecules and DNA, form plasmid nano-microspheres under the condition of rapid stirring at 80 rpm .

[0035] (3) The biological gl...

Embodiment 3

[0037] (1) in CaO-P 2 o 5 -SiO 2 P123 was added to the system, and the parameters of the electrospinning process were: electrostatic voltage 20Kv, acceptance distance 20cm, spinning rate 5ml / h, relative humidity 50%. The high-speed rotating drum rotates at 400rpm to obtain regularly arranged micro-nano fibers; the fibers are sintered at a temperature of 380°C for 150 minutes to make the surfactant on the fibers evaporate violently, thereby forming a pore structure on the surface of the fibers and obtaining mesoporous organisms Glass micro-nanofibers.

[0038] (2) Extract the Osterix target gene fragment, construct the target gene plasmid, and obtain the plasmid DNA recombinant by gene recombination technology. Mix the chitosan solution and plasmid DNA recombinant, the mixing mass ratio range is 3:1, utilize the attractive force between chitosan molecules and DNA, form plasmid nano-microspheres under the condition of rapid stirring at 80 rpm .

[0039] (3) The biological g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com