Calcium carbonate particle composition and preparation method thereof

A technology of calcium carbonate and composition, applied in the field of calcium carbonate particle composition and preparation thereof, can solve the problems of easy increase of gastrointestinal adverse reactions, poor absorption, etc., and achieve easy industrial production and popularization and application, good stability, and easy operation. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

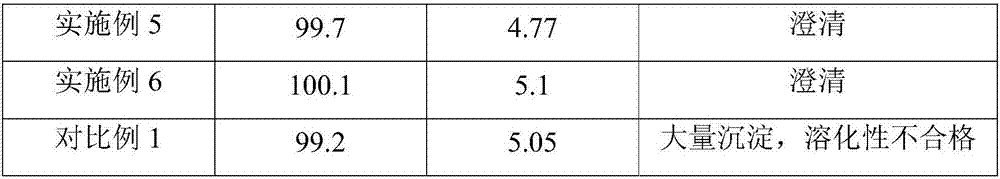

Examples

Embodiment 1

[0024] (1) Oyster calcium carbonate powder and white granulated sugar powder are passed through an 80-mesh sieve respectively, and 75.2 g of sieved oyster calcium carbonate powder, 2809 g of sieved white granulated sugar powder, 115.8 g of citric acid, and 0.044 g of tartrazine are weighed;

[0025] (2) Take 93.5g of white granulated sugar powder and add purified water to prepare a syrup with a mass ratio concentration of 50%. Put 75.2g of sieved oyster calcium carbonate and 1425g of white granulated sugar powder into manual sieve and mix for 3 times, then add Syrup and an aqueous pigment solution prepared by dissolving 0.022g of pigment in 10g of purified water, made into a soft material, wet granulated, dried at 50°C for 120min, and granulated to obtain 30-mesh calcium carbonate granules;

[0026] (3) Mix 115.8g of citric acid with 47g of purified water, fully dissolve it, add the remaining powdered sugar and dissolve 0.022g of pigment in 10g of purified water to make a soft ...

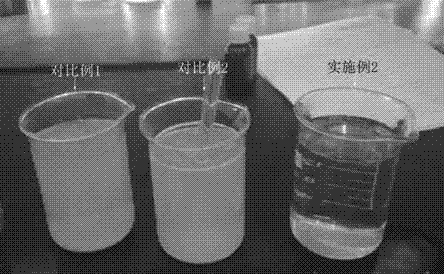

Embodiment 2

[0029] (1) Oyster calcium carbonate powder and white granulated sugar powder are passed through 80 mesh sieves respectively, weigh 1003g of sieved oyster calcium carbonate powder, 37500g of sieved white granulated sugar powder, 1544g citric acid, 0.595 tartrazine;

[0030] (2) Get 1250g of white granulated sugar powder and add purified water to be mixed with a mass ratio concentration of 50% syrup, put the sieved oyster calcium carbonate 1003 and white granulated sugar powder 12300g into a high-efficiency mixer and mix for 3min, then add the syrup and use Dissolve 0.198g pigment aqueous solution in 100g purified water to make soft material, wet granulate, dry in fluidized bed at 60-65℃ for 15min, and granulate to obtain 60 mesh calcium carbonate granules;

[0031] (3) Mix 1544g of citric acid with 1003.6g of purified water, fully dissolve it, add the remaining powdered sugar and dissolve 0.397g of pigment in 100g of purified water to make a soft material, wet granulate, first u...

Embodiment 3

[0034] (1) Oyster calcium carbonate powder and white granulated sugar powder are passed through an 80-mesh sieve respectively, and 100 g of sieved oyster calcium carbonate powder, 3000 g of sieved white granulated sugar powder, 120 g of citric acid, and 0.01 g of tartrazine are weighed;

[0035] (2) Get 100g of white granulated sugar powder and add purified water to be mixed with a mass ratio concentration of 35% syrup, 100g of sieved oyster calcium carbonate and 900g of white granulated sugar powder are manually sieved and mixed for 3 times, then add the syrup and use 10g The pigment aqueous solution prepared by dissolving 0.005g of pigment in purified water is made into a soft material, wet granulated, dried at 50°C for 120min, and granulated to obtain 12-mesh calcium carbonate granules;

[0036] (3) Mix 120g of citric acid with 48g of purified water, fully dissolve it, add the remaining powdered sugar and dissolve 0.005g of pigment in 10g of purified water to make a soft mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com