Nursing feed for Bama miniature pigs and preparation method thereof

The technique of a Bama-scented pig and its production method, which is applied in the field of animal husbandry, can solve the problems that the Bama-scented pig is not nutritionally balanced, that the Bama-scented pig is prone to disease, and that the growth and development of the Bama-scented pig is slow. Effects of immunity and disease resistance, improvement of quality and food safety, promotion of healthy and rapid growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

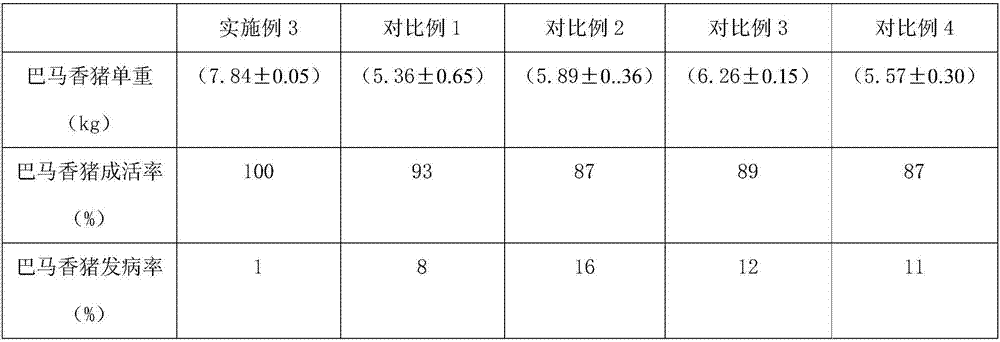

Examples

Embodiment 1

[0031] Nursery feed for Bama pigs

[0032] (1) The feed is made by mixing the following raw materials by weight: 18 parts of puffed corn, 45 parts of northeast corn, 6 parts of wheat bran, 18 parts of soybean meal, 2 parts of fish meal, 0.7 part of stone powder, 0.8 part of calcium hydrogen phosphate, 0.2 parts of salt, 2 parts of premix, 1 part of additives, 1.2 parts of plant extracts; of which,

[0033] The production method of the puffed corn is to add 5wt% water to the corn flour, mix and stir evenly, then put the obtained mixture into an extruder, and extrude under a pressure of 36MPa to obtain puffed corn;

[0034] The production method of the fish meal is to cook the fish with steam, remove the body fat of the fish, and then press the obtained solid matter by a screw press method, place the obtained solid part in a drying room, and steam under the condition of a temperature of 125 ° C. Dry to obtain the fish meal;

[0035] The premix is made by mixing vitamins, swe...

Embodiment 2

[0044] Nursery feed for Bama pigs

[0045] (1) The feed is made by mixing the following raw materials by weight: 25 parts of puffed corn, 50 parts of northeast corn, 8 parts of wheat bran, 20 parts of soybean meal, 2.5 parts of fish meal, 0.8 part of stone powder, 0.9 part of calcium hydrogen phosphate, 0.3 parts of table salt, 4 parts of premix, 3 parts of additives, 1.5 parts of plant extracts; of which,

[0046] The production method of the puffed corn is to add 5wt% water to the corn flour, mix and stir evenly, then put the obtained mixture into an extruder, and extrude under a pressure of 40 MPa to obtain puffed corn;

[0047] The production method of the fish meal is to cook the fish with steam, remove the body fat of the fish, and then press the obtained solid matter by a screw press method, place the obtained solid part in a drying room, and steam under the condition of a temperature of 135 ° C. Dry to obtain the fish meal;

[0048] The premix is made by mixing vit...

Embodiment 3

[0057] Nursery feed for Bama pigs

[0058] (1) The feed is made by mixing the following raw materials by weight: 22 parts of puffed corn, 48 parts of northeast corn, 7 parts of wheat bran, 19 parts of soybean meal, 2.2 parts of fish meal, 0.75 part of stone powder, 0.85 part of calcium hydrogen phosphate, 0.25 parts of salt, 3 parts of premix, 2 parts of additives, 1.3 parts of plant extracts; of which,

[0059] The production method of the puffed corn is to add 5wt% water to the corn flour, mix and stir evenly, then put the obtained mixture into an extruder, and extrude under a pressure of 38MPa to obtain puffed corn;

[0060] The production method of the fish meal is to cook the fish with steam, remove the body fat of the fish, and then press the obtained solid matter by a screw press method, place the obtained solid part in a drying room, and steam under the condition of a temperature of 132 ° C. Dry to obtain the fish meal;

[0061] The premix is made by mixing vitamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com