Composite electric heating grain dryer

A grain dryer and electric heating technology, applied in the direction of drying and preserving seeds, can solve the problems of uneven grain drying, inability to equip hot air temperature, poor grain quality, etc., and achieve good grain drying quality and grain drying The effect of high drying efficiency and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

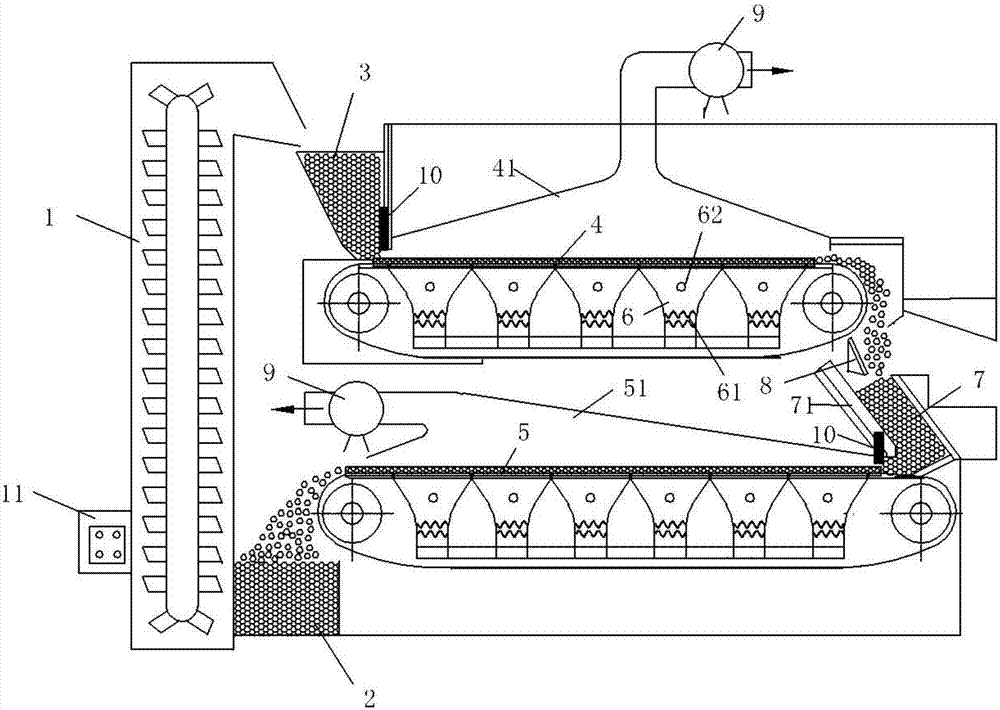

[0016] A composite electric heating grain dryer, comprising a feeder 1, a silo 2 and a drying device, the drying device is arranged above the silo 2, the outlet of the feeder 1 is connected to the inlet of the drying device, and It is characterized in that the drying device includes an upper drying chamber and a lower drying chamber, the upper drying chamber is provided with a first crawler conveyor belt 4, a hot air chamber 6 is provided below the first crawler conveyor belt 4, and the lower drying chamber is provided with Below the first crawler conveyor belt 4, a second crawler conveyor belt 5 is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com