Multiple degree of freedom finished wire product moving mechanism

A material-moving mechanism and degree-of-freedom technology, applied in the directions of manipulators, program-controlled manipulators, claw arms, etc., can solve the problems of inability to move materials at multiple angles, low efficiency, and limited freedom of the material-moving mechanism, so as to reduce manual labor. quantity, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

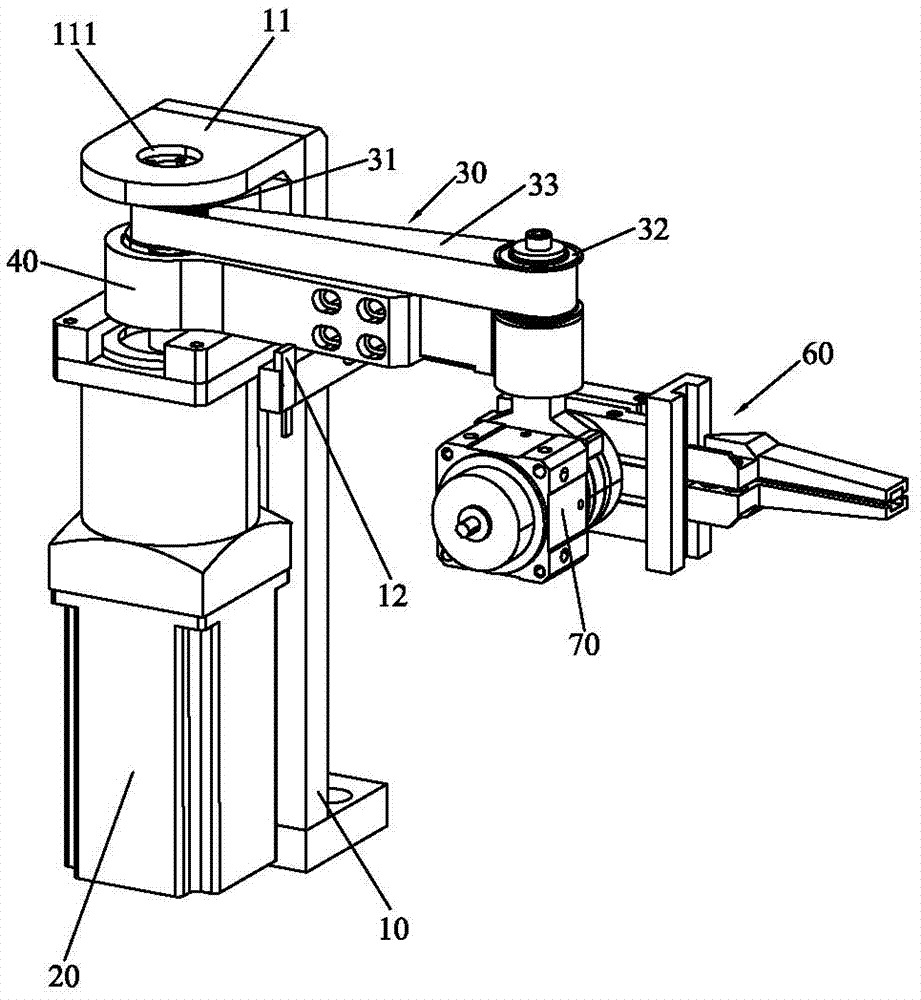

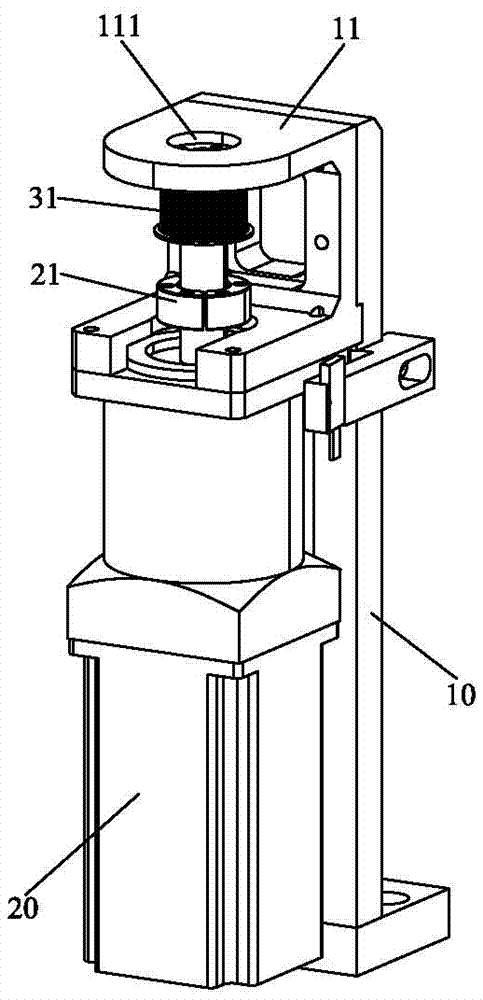

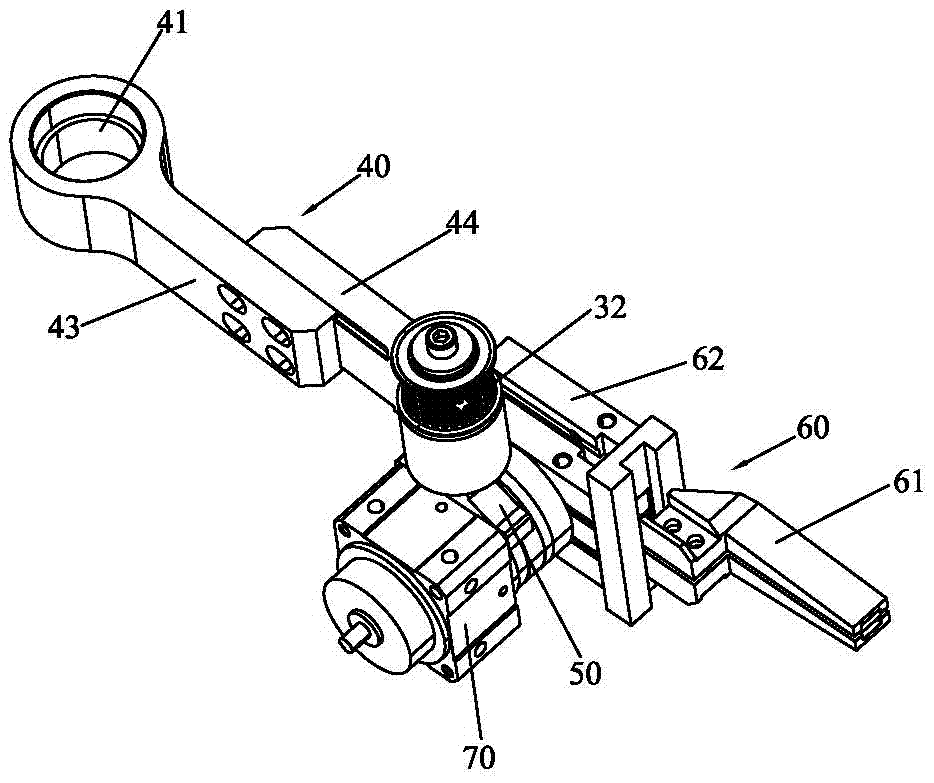

[0033] The present invention as Figure 1 to Figure 5 As shown, a multi-degree-of-freedom wire product moving mechanism includes a bracket 10, a driving motor 20, a belt transmission assembly 30, a swing rod 40, a support member 50, a movable gripper 60, and a driving cylinder for driving the movable gripper 60 to rotate. 70, of which:

[0034] The support 10 is vertical, and an extension plate 11 is provided on the upper end of the support 10, and a through hole 111 is provided on the extension plate 11; Displacement sensor 12.

[0035] The driving motor 20 is installed vertically on the bracket 10 ; the top of the shaft end of the driving motor 20 is pivotally connected to the above-mentioned through hole 111 , and a fixed block 21 is installed on the shaft end of the driving motor 20 .

[0036] The belt drive assembly 30 includes a driving wheel 31 , a driven wheel 32 and a transmission belt 33 sleeved on the driving wheel 31 and the driven wheel 32 . The driving wheel 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com