Intelligent robot for tour inspection of power equipment

A technology of intelligent robots and power equipment, applied in the field of intelligent robots, to achieve the effect of ensuring work stability and realizing lighting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as Figure 1~2 As shown, this embodiment includes a main body 1, on which a traveling mechanism, a motor for driving the traveling mechanism, a controller, and a detection head 5 electrically connected to the controller are arranged, and on the said main body 1 there is a Cavity 2, the motor is fixed in the cavity 2, the cover plate 4 is hingedly arranged on the body 1, a plurality of interconnected grooves are opened on the body 1, and the bottom of the cover plate 4 is provided with four Enclosed to form a rectangular corrugated strip, and an elastic rubber sheet 41 is provided on both side walls of the corrugated strip. The middle section of the elastic rubber sheet 41 protrudes outward, so that a gap is formed between the elastic rubber sheet 41 and the corrugated strip side wall. The longitudinal section is a semicircular gap, and the gap is filled with large-pore silica gel particles 42. When the cover plate 4 seals the cavity 2, the elastic rubber sheet 41 i...

Embodiment 2

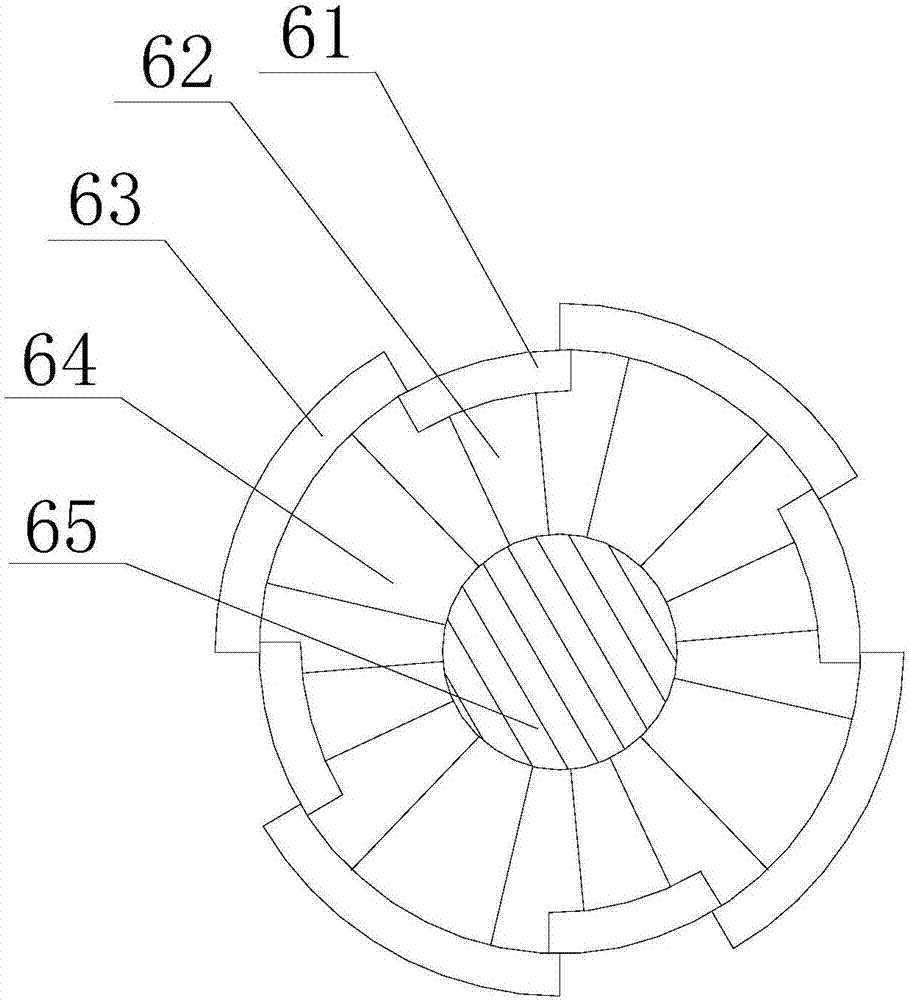

[0038] Such as Figure 1~6 As shown, this embodiment is based on Embodiment 1, the solar cell panel group 6 includes a solar cell panel I61 and a solar cell panel II63, and the solar cell panel I61 is hinged to the outer wall of the central shaft 65 through a connector I62 , the solar cell panel II63 is hinged to the central axis 65 through the connecting piece II64. The solar battery panel group 6 includes a solar battery panel I61 and a solar battery panel II63, and the solar battery panel I61 is movably connected with the central axis 65 through the connector I62 and the solar battery panel II63 respectively through the connector II64. Upward solar cell panels I61 and solar cell panels II63 are staggered to form a daylighting plane, and two different solar cell panels are used to make the adjacent solar cell panels not interfere with each other when rewinding in the reel 3, so that For fast retraction or expansion of solar panels.

[0039]Further, the connecting piece I62...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com