Damping unit, damping device and engine test system using damping device

A vibration damping device and test system technology, which is applied in the direction of engine testing, shock absorbers, measuring devices, etc., can solve the problems of different vibration damping requirements of vibration damping devices, poor adaptability of vibration damping measures, damage to turbochargers, etc., to achieve The effect of avoiding supercharger damage, improving adaptability and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

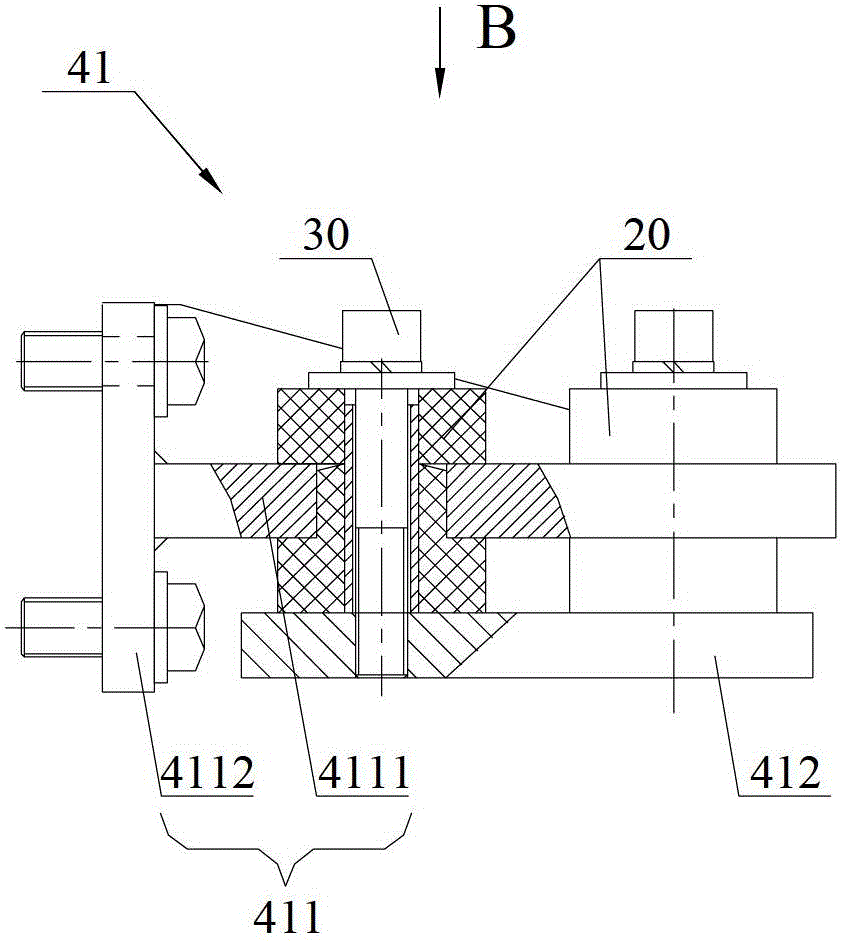

[0029] The core of the invention is to provide a vibration damping unit, which is used for vibration damping in the test and detection process of different types of engines, and has better adaptability. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

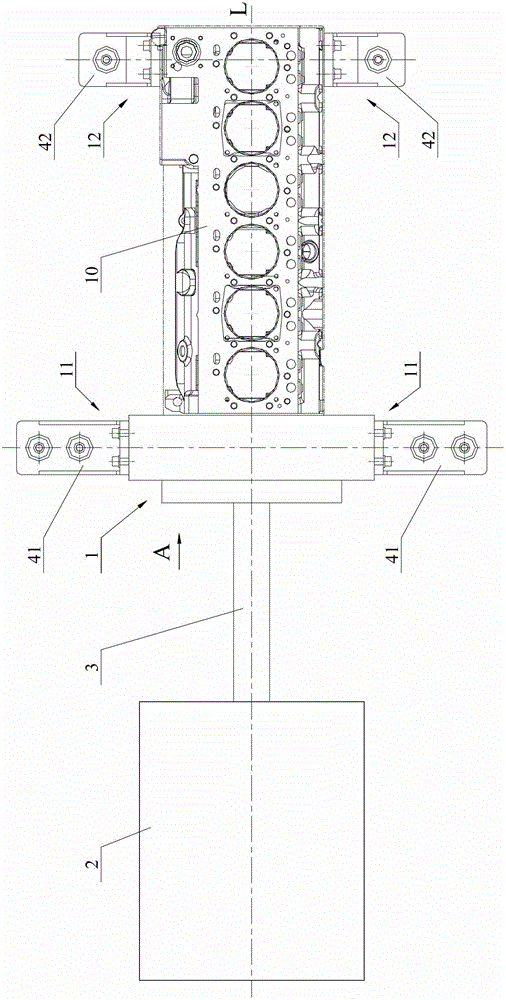

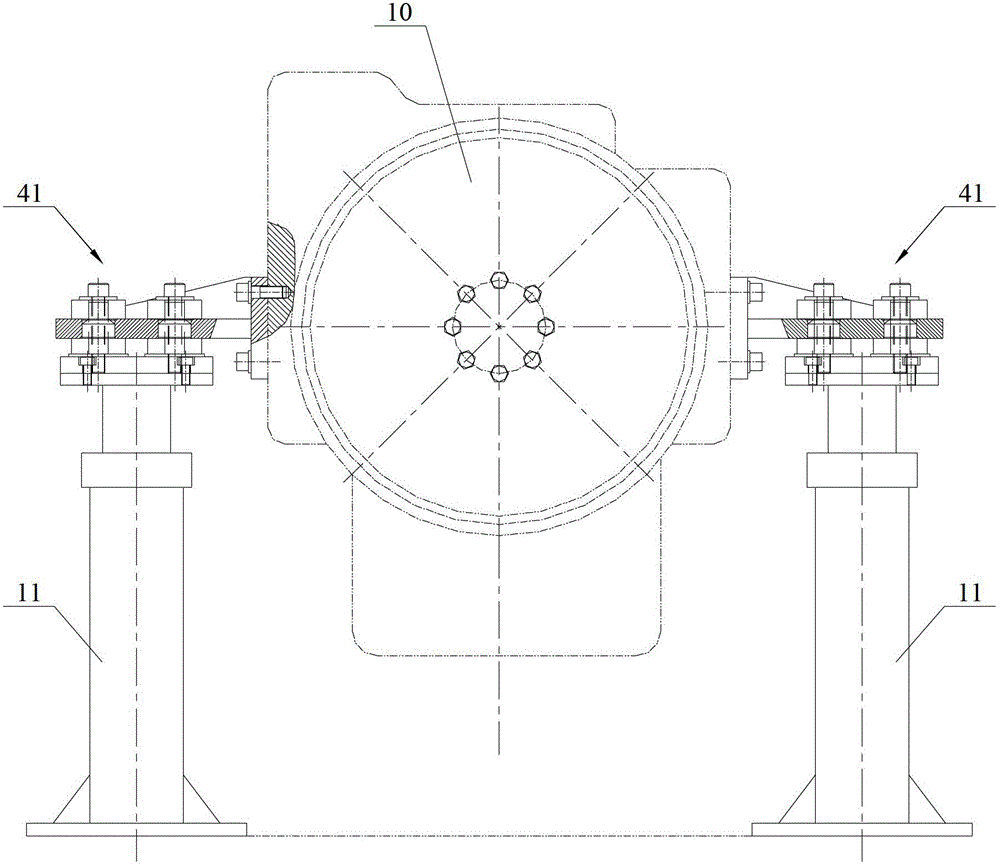

[0030] See figure 1 and figure 2 ,in, figure 1 It is a top view of the engine test system described in this embodiment; figure 2 for figure 1 A view of A, the figure does not show the dynamometer.

[0031] Same as the prior art, the engine test system includes a bench device 1 for carrying the engine to be tested 10, a dynamometer 2 and a transmission shaft 3 connecting the dynamometer 2 and the crankshaft of the engine to be tested 10; The dynamometer 2 measures the running data of the engine 10 .

[0032] combine figure 1 and figure 2 As shown, two sets of supporting devices are arranged on the platform device 1, and the two supporting devices of each group are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com