Compensation method and device for engine crankshaft signal and automobile

A compensation method and compensation device technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inaccurate crankshaft tooth period and inaccurate engine system control, so as to improve accuracy and control system stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention are described in detail below. Examples of the embodiments are shown in the accompanying drawings, in which the same or similar reference numerals indicate the same or similar elements or elements with the same or similar functions. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention, but should not be construed as limiting the present invention.

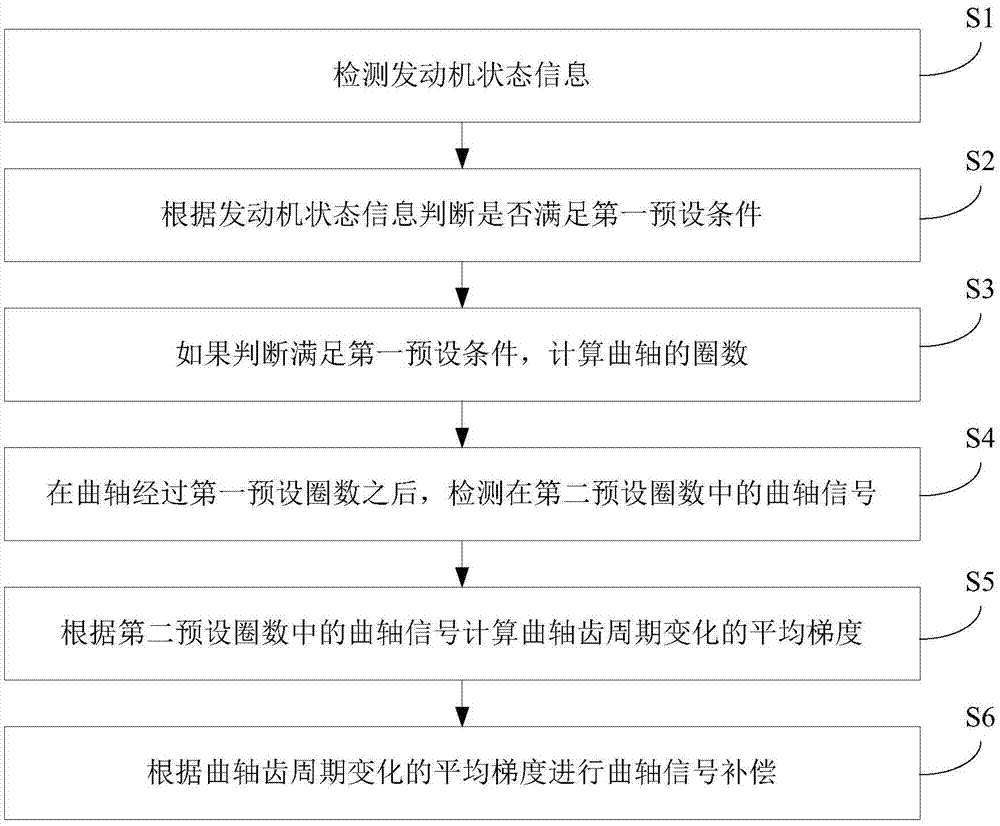

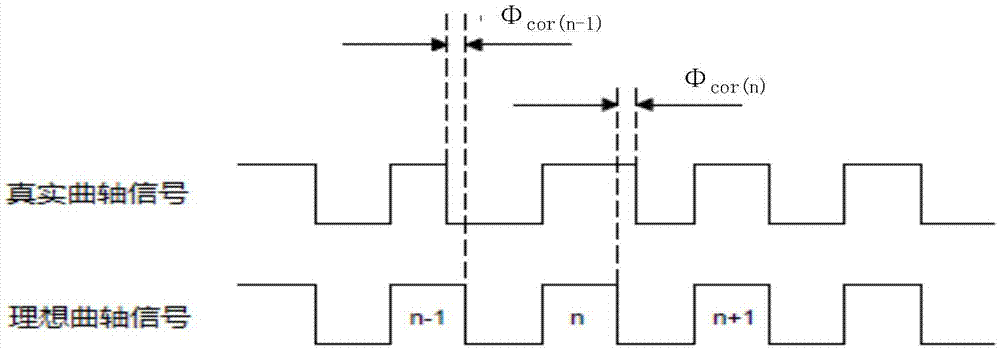

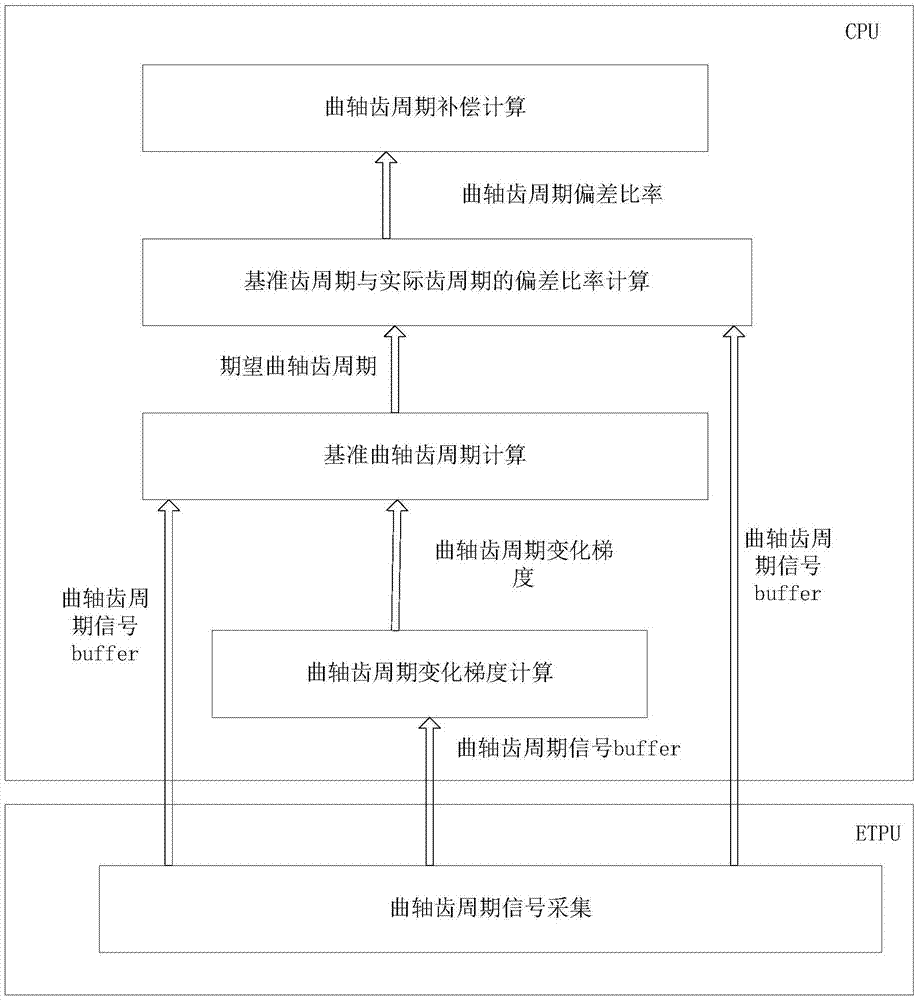

[0033] In theoretical calculations, the angle of each tooth of the crankshaft is fixed, but due to the mechanical error in crankshaft processing and the bending or deformation of the crankshaft teeth that may occur during engine operation, the crankshaft tooth angle is not a completely accurate fixed value. This will result in a certain deviation of the controlled engine angle, which will affect the control accuracy. In order to solve the above-mentioned problems, the present invention proposes a meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com