Laboratory steam dryness monitoring device, monitoring method and steam flooding experimental device

A monitoring device and laboratory technology, applied in the direction of humidity control, measuring device, earthwork drilling and mining, etc., can solve the problems of effect influence, large error, and inability to obtain accurate measurement of steam dryness, so as to realize automatic control and reduce personnel workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

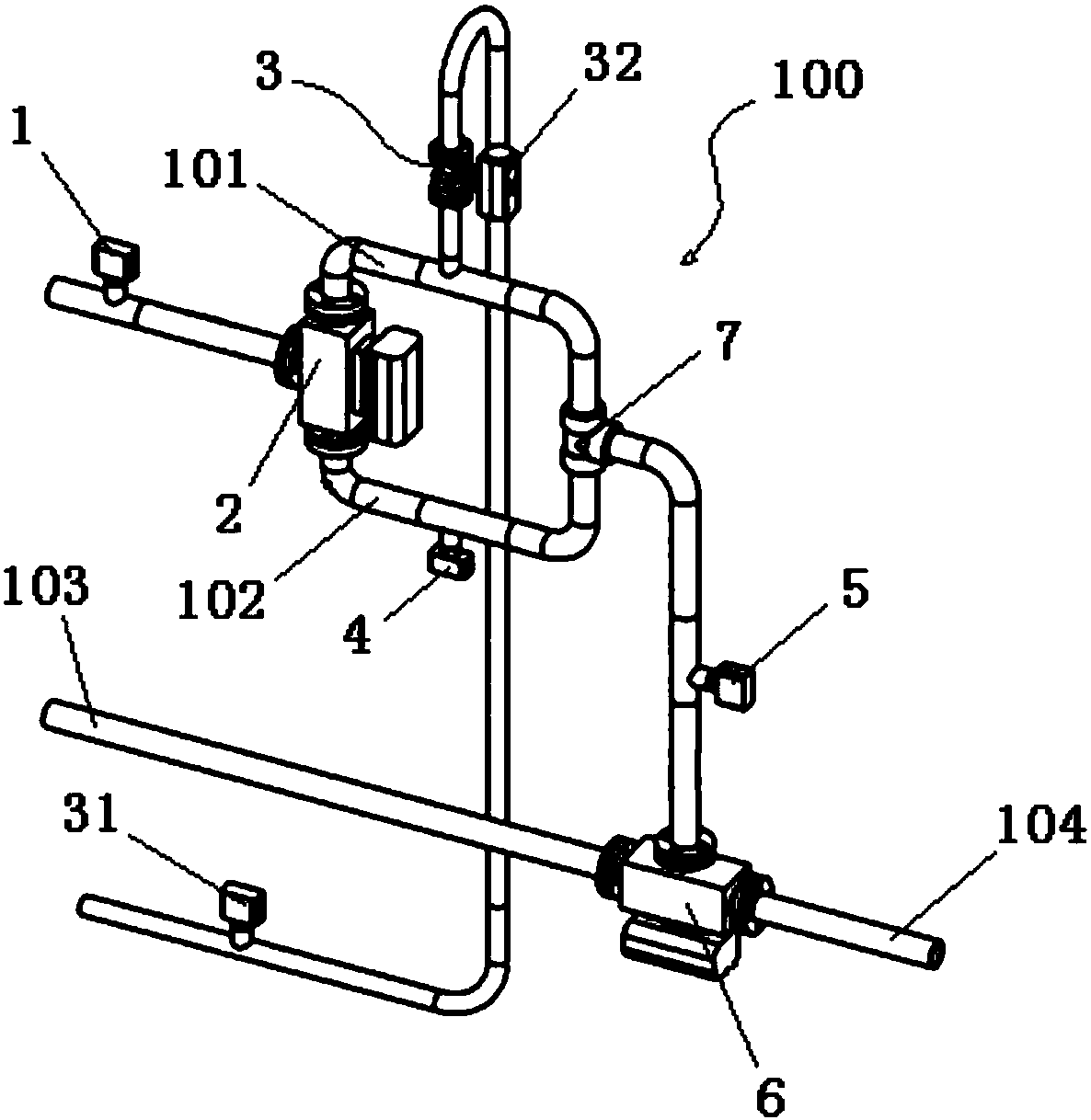

[0041] like figure 1As shown, the present invention provides a laboratory steam dryness monitoring device 100, which is used to monitor and control the steam dryness of the output steam, so that the output steam dryness accurately conforms to the set value. The laboratory steam dryness monitoring device 100 includes a first detection device 1 , a first electromagnetic three-way valve 2 , a water adding device 3 , a heating device 4 , a second detection device 5 and a second electromagnetic three-way valve 6 . The first detection device 1 is connected to the steam generator through a pipeline, and is used for detecting the steam dryness of the steam output by the steam generator. Preferably, the first detection device 1 adopts an optical fiber steam dryness measurer; the first detection device 1 has a measurement channel for steam to pass through. The fiber optic steam dryness measuring instrument is one of the existing measuring devices for measuring steam dryness. The fiber...

Embodiment 2

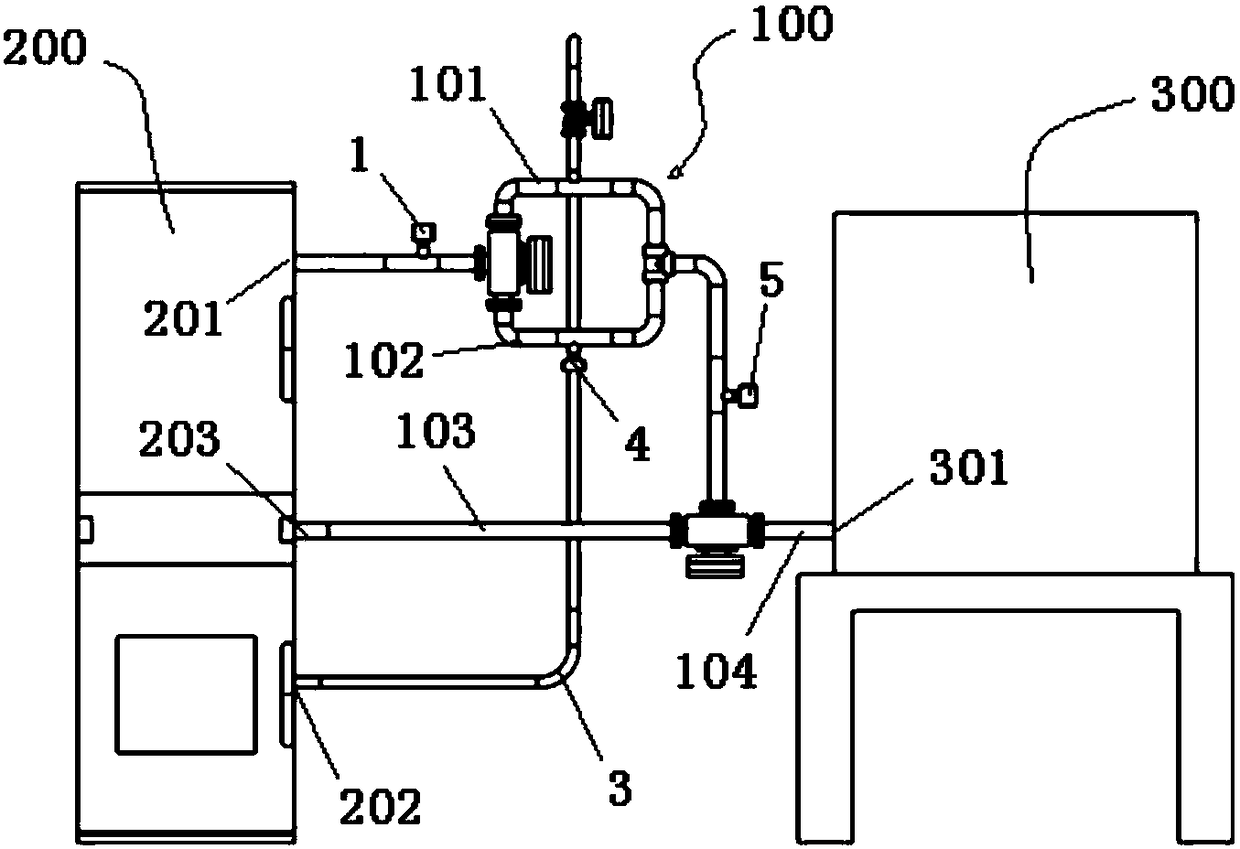

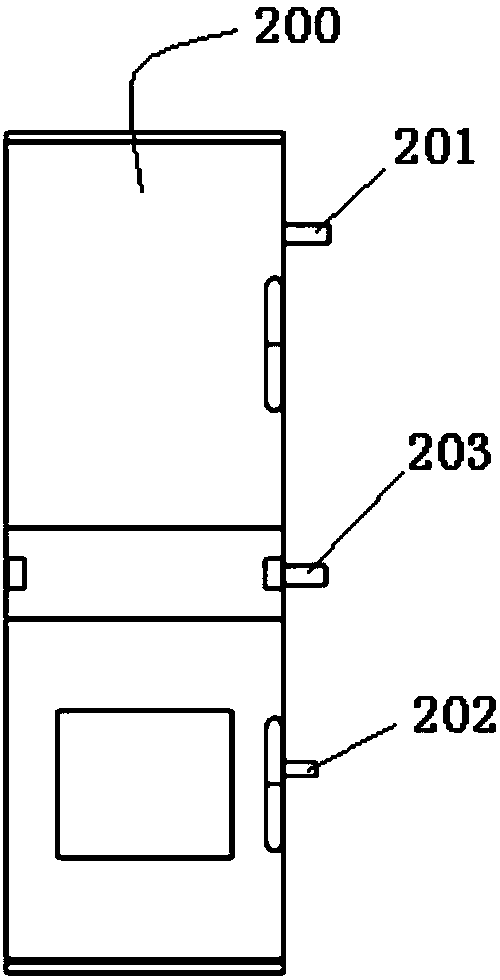

[0051] like figure 2 , image 3 and Figure 4 As shown, this embodiment provides a laboratory steam flooding experimental device, which is used for the simulation experiment of steam flooding in the laboratory, which adopts the laboratory steam dryness monitoring device 100 described in the first embodiment, The laboratory steam flooding experimental device further includes a steam generator 200 and a steam flooding model 300 . The steam generator 200 can adopt the existing technology, including a steam output port 201 , a soft water output port 202 and a steam recovery port 203 . The steam output port 201 is connected to the first detection device 1 through a pipeline. The soft water output port 202 is connected to the water adding device 3 through a pipeline. The steam recovery port 203 is connected to the steam recovery pipeline 103 . The steam flooding model 300 can use an existing experimental model, which has a steam injection port 301 , and the steam injection por...

Embodiment 3

[0054] like Figure 5 As shown, this embodiment provides a laboratory steam dryness monitoring method, Figure 5 The steam parameter testing devices in , respectively represent the first detection device and the second detection device; injecting into the physical model means injecting steam into the steam flooding model. The laboratory steam dryness monitoring method adopts the laboratory steam dryness monitoring device 100 described in Embodiment 1, including the following steps:

[0055] S1. Detect the steam dryness of the steam output from the steam generator 200.

[0056] S2. Distribute steam according to the steam dryness value detected in step S1; if the detected steam dryness value is less than the set steam dryness value, distribute the steam to the heating pipeline 102 to heat the steam; if If the detected steam dryness value is greater than the set steam dryness value, the steam is distributed to the water adding pipeline 101, and distilled water is mixed into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com