Coal mine inspection collection system

A collection system and coal mine technology, which is applied in the field of coal mine inspection and collection system, can solve the problems of inaccurate inspection, difficult sampling, large coal lumps, etc., and achieve the effect of accurate inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

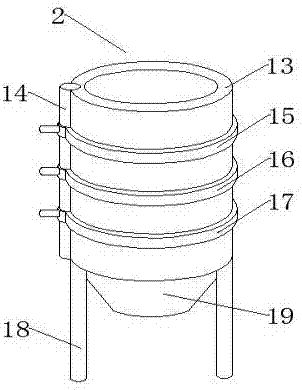

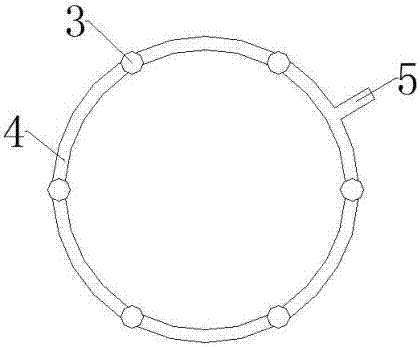

[0016] A coal mine inspection and collection system mainly includes a pulverizing device 1 and a filtering device 2. Coal samples passing through the pulverizing device 1 are sent to the filtering device 2 through a conveyor belt. The pulverizing device 1 includes a sprinkler nozzle 3, an annular water pipe 4, a water inlet 5, Water pipe 6, electric water pump 7, box body 8, pulverized layer A9, pulverized layer B10, discharge port A11 and bracket 12, the water sprinklers 3 are installed at the bottom of the annular water pipe 4 at equal intervals through sealant, and the water inlet 5 is arranged on the side of the annular water pipe 4, and the water inlet 5 is connected to the water delivery pipe 6, the water delivery pipe 6 is connected to the electric water pump 7, and the water delivery pipe 6 is installed on the outer wall of the box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com