Special detection device for 30-DEG inclined hole in gear pump upper cover

A testing equipment, gear pump technology, applied in mechanical depth measurement, mechanical clearance measurement, etc., can solve the problems of increasing the probability of errors, complicated and cumbersome testing process, inaccurate measurement results, etc., to improve accuracy and simplify the measurement process. , the effect of speeding up the measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

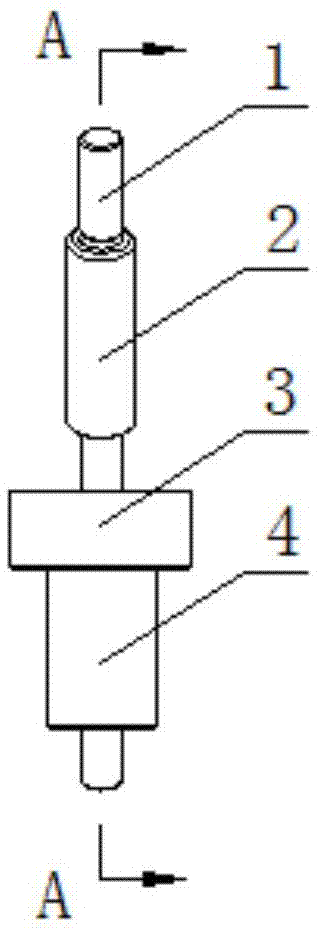

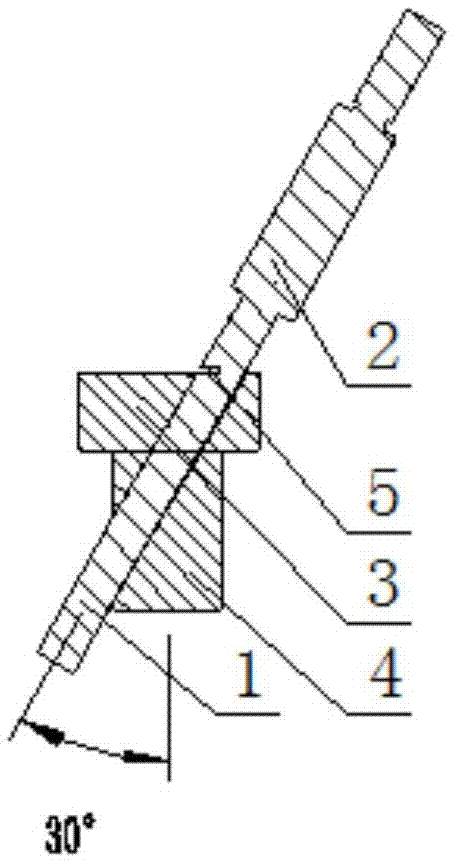

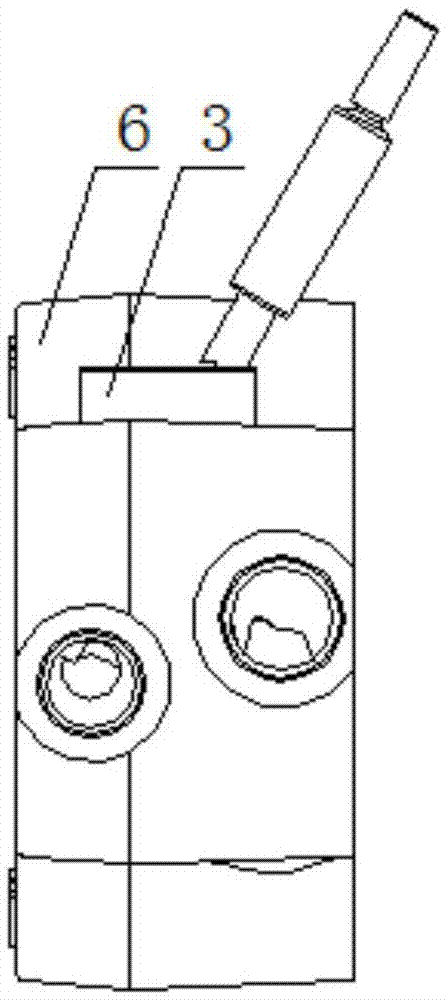

[0018] A special detection device for a 30-degree inclined hole on the upper cover of a gear pump, including a positioning sleeve and a measuring rod 1. The positioning sleeve includes a cylinder 4 and a cylinder base 3. The cylinder and the cylinder base are coaxially made, and the cylinder The platform is arranged above the cylinder, and the diameter of the cylinder platform is greater than the diameter of the cylinder, and the diameter of the cylinder coincides with the diameter of the side hole of the workpiece, so as to be inserted into the side hole of the workpiece.

[0019] A slant measurement hole with an inclination angle of 30 degrees is made on the cylindrical platform. The lower end of the slant meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com