Lock bolt component

A technology for preventing loosening of bolts and bolts, applied in the direction of bolts, threaded fasteners, screws, etc., can solve the problem of easily damaged connecting parts or connected parts, and the torsion of stop pads is small and good, but it is necessary to drill holes on the bolts. The specific position of the bolt needs to be preset in advance, so as to achieve the effect of good anti-loosening effect and mature and reliable technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] The first embodiment of the present invention

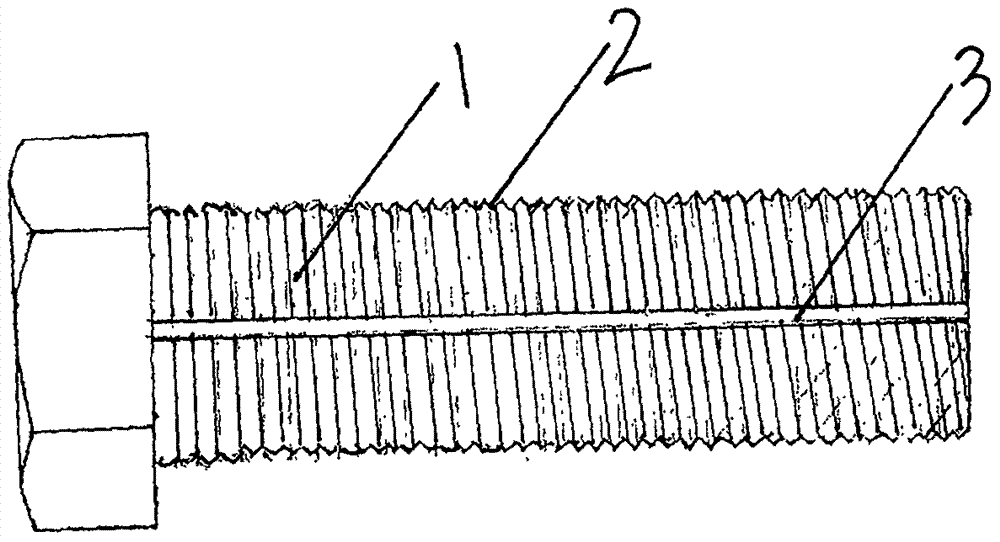

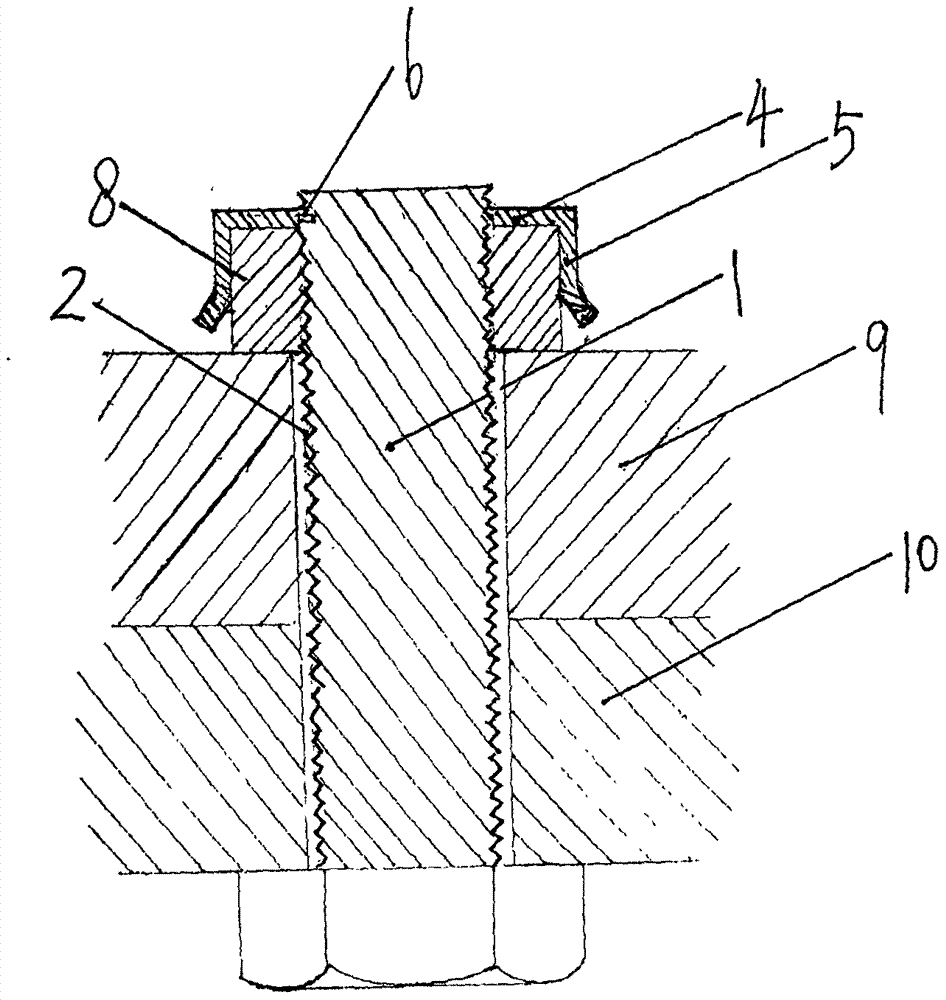

[0022] refer to figure 1 , figure 2 , image 3 . exist figure 1 Among them, 1 is the bolt in the anti-loosening bolt assembly, and the thread 2 is on the bolt. A stop groove 3 is arranged on the top of the bolt 1 . The number of the stop grooves 3 can also be set to two, three or more as required. The length of the stop groove 3 can be set to be 1 / 2 of the bolt length, 1 / 3 of the bolt length, etc. in addition to being set to be equal to the bolt length.

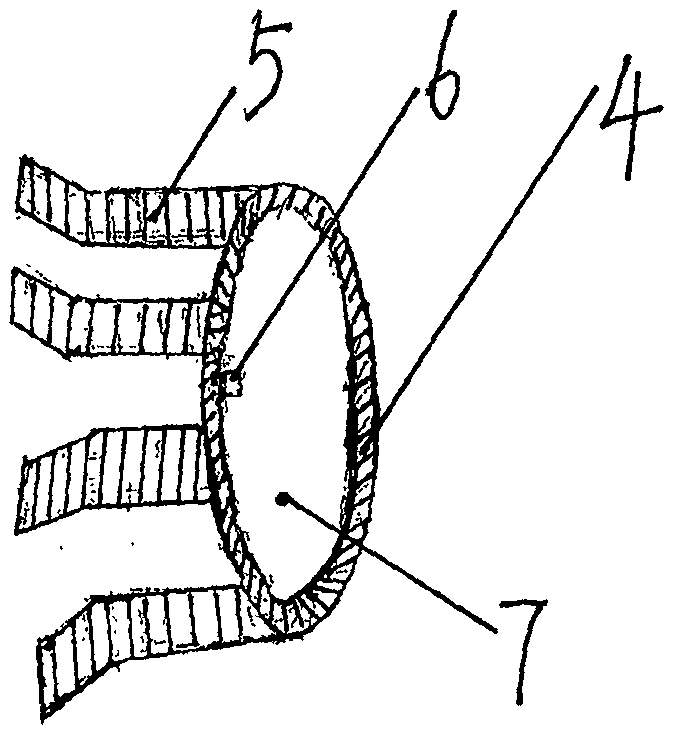

[0023] exist figure 2 Among them, the ring piece 4, the pressing piece 5, the stop protrusion 6, and the bolt channel hole 7 jointly form the stop snap ring sleeve. A compression piece 5 that can produce elastic deformation is fixed on the ring piece 4 of the stop snap ring sleeve, for example: a steel sheet with better elasticity can be used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com