Triangular steel pile foundation of offshore wind power engineering and construction method of delta-shaped steel pile foundation

An offshore wind power, character-shaped technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of large construction ships entering, low construction efficiency, and difficult construction, so as to reduce construction costs, facilitate construction operations, and reduce construction difficulties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] See attached picture:

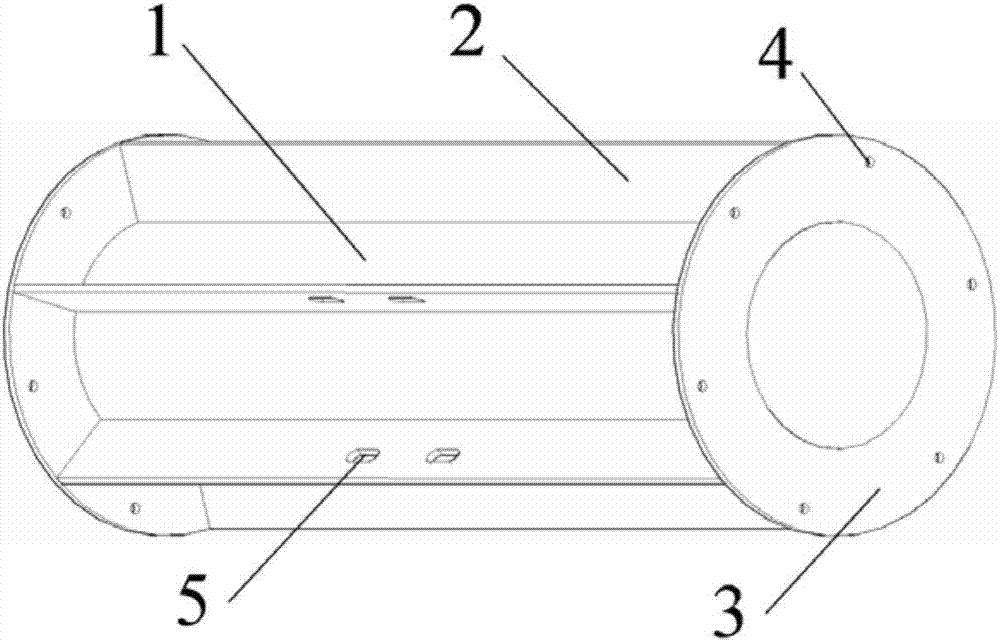

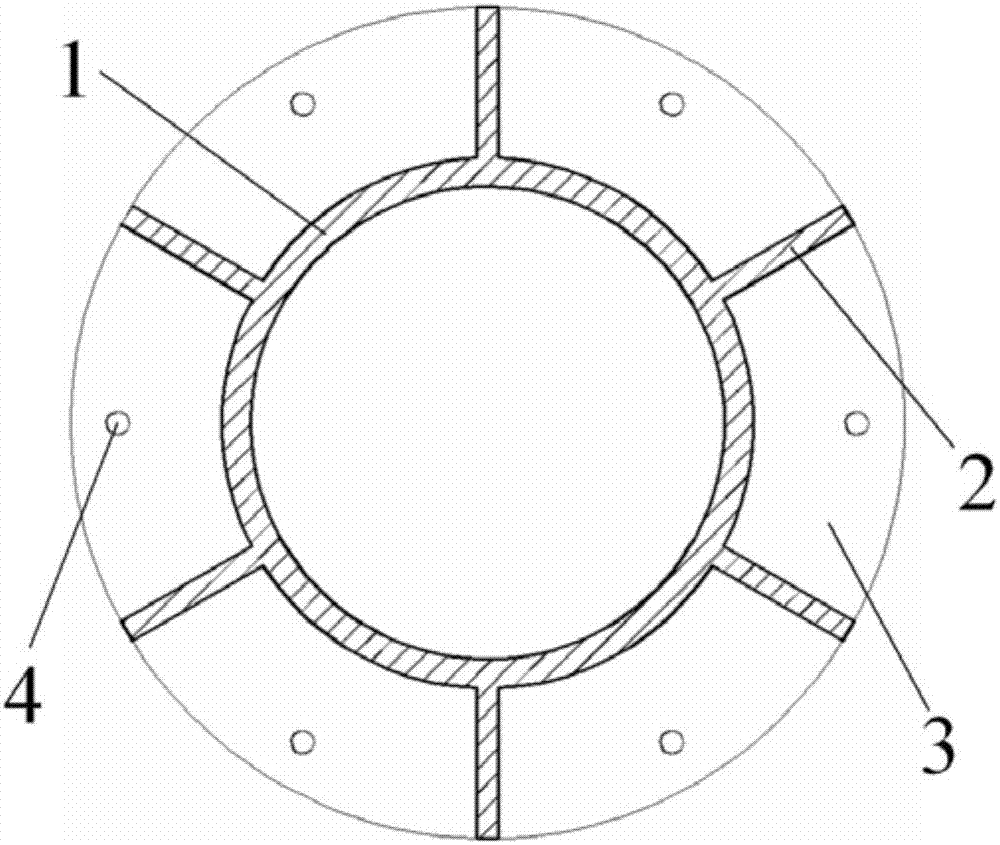

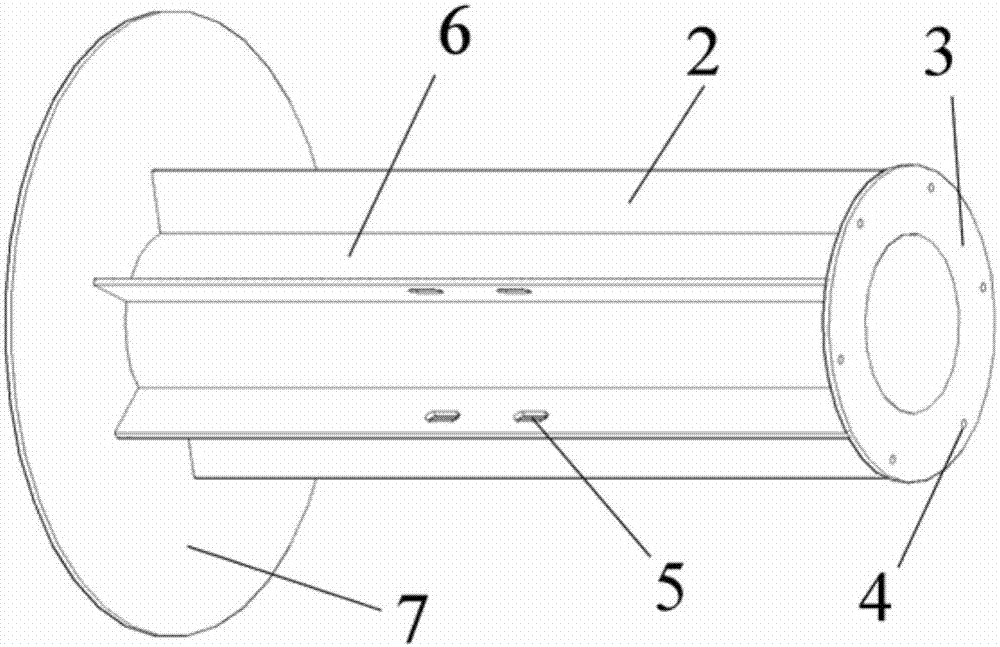

[0062] A character-shaped steel pile foundation for an offshore wind power project, comprising three steel piles 16 distributed in a character-shaped pattern and pile outer sleeves, the pile outer sleeve consists of a sleeve bottom section 6, multiple sleeve standard sections 1, and a sleeve The top section 12 is formed by connecting the connecting plate 8 and the bolts to each other. After assembly, the outer sleeve of the pile in the shape of a Chinese character covers three steel piles 16, sinks into the seabed and presses on the supporting plate 17 and the fixing frame 9. The supporting plate 17 is a circular steel plate , the inner hole of the circular steel plate matches the outer wall of the steel pile 16, and the fan tower 15 is connected to the top section 12 of the sleeve. The gravity of the fan is directly transmitted to the seabed based on the sleeve outside the pile. The three steel piles 16 are jointly borne by the seabed soil, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com