Neutral hard scale softening agent for three-component compound flooding screw pump well

A ternary compound, screw pump technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of reduced pump efficiency, leakage of screw pumps, enlarged stator and rotor gaps, etc. The effect of improving permeability and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] Specific embodiments: the present invention will be further described below in conjunction with examples: it is made up of organic phosphate, organic phosphonate, dispersant, alkali and water, and their weight percent is: organic phosphate 10~40%, organic phosphate 2-10%, dispersant 1-5%, alkali 1-3%, water 50-80%.

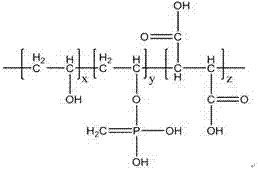

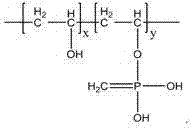

[0026] The organic phosphate can be any one of acrylic acid-vinyl alcohol phosphate copolymer, maleic acid-vinyl alcohol phosphate or polyvinyl alcohol phosphate.

[0027] The organic phosphonate can be tetrasodium aminotrimethylene phosphonate, potassium aminotrimethylene phosphate, tetrasodium 2-phosphonic acid butane-1,2,4-tricarboxylic acid or ethylenediamine tetramethylene phosphonic acid Any of the pentasodium.

[0028] The dispersant can be any one of sodium polyacrylate, sodium polymaleate or hydrolyzed polymaleic anhydride.

[0029] Described alkali can be any one in sodium hydroxide, potassium hydroxide, sodium carbonate or potassium carbonate. ...

Embodiment 1

[0035] Embodiment 1: it is made up of acrylic acid-vinyl alcohol phosphate copolymer, tetrasodium aminotrimethylene phosphonate, polysodium maleate, sodium hydroxide, water, and their weight percent is: acrylic acid-vinyl alcohol phosphate copolymer 25%, tetrasodium aminotrimethylene phosphonate 5%, sodium polymaleate 2%, sodium hydroxide 2%, water 66%. This example shows the field test results of neutral hard scale softeners.

[0036] This example is used in the screw pump well C271-SP12 of the second class upper return block in the west area of Daqing Oilfield. The current of the screw pump well rises from 51A to 63A due to scale deposition in this well. The current of the oil well recovers after being treated with a neutral hard scale softener Normally reduced to 52A, the oil well produced normally, and no leakage occurred; it was used in the screw pump well N4-10-P3039 in the upper return block in the eastern part of the South Fourth District of Daqing Oilfield. After the...

Embodiment 2

[0037] Embodiment 2: It is made up of maleic acid-vinyl alcohol phosphate copolymer, 2-phosphonic acid butane-1,2,4-tetrasodium tricarboxylate, sodium polyacrylate, potassium hydroxide, water, their weight The percentages are: maleic acid-vinyl alcohol phosphate copolymer 25%, tetrasodium 2-phosphonic acid butane-1,2,4-tricarboxylate 5%, sodium polyacrylate 2%, potassium hydroxide 3%, water 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com