A kind of anticorrosion coating based on fluorosilicone modified acrylic resin and its preparation

An acrylic resin, fluorosilicon modification technology, applied in the polymer field, can solve the problems of uneven distribution of fluorosilicon groups, unstable performance of anti-corrosion coatings, etc., to achieve stable corrosion resistance, good corrosion resistance, and improved corrosion resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

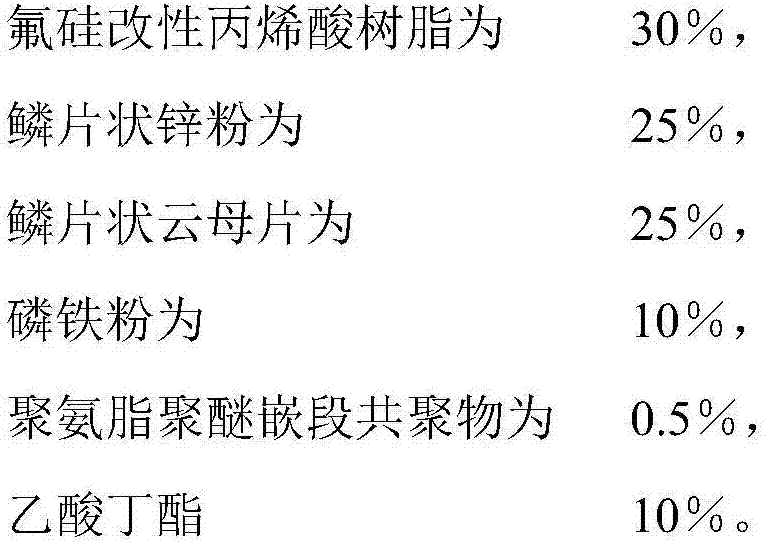

[0025] 1. The mass percentage of raw materials and dosage is

[0026]

[0027] 2. Preparation method

[0028] Step 1: Mix perfluoroalkyl ethyl alcohol and diphenylmethane diisocyanate at a molar ratio of 1:1.2, add dibutyltin dilaurate accounting for 2% of the total weight of the reaction solution, and react under anhydrous conditions for 5 hours. The reaction temperature is 60°C;

[0029] Step 2: Take the liquid after the reaction in step 1, add polydimethylsiloxane according to the molar ratio of perfluoroalkyl ethyl alcohol content in the liquid to polydimethylsiloxane as 1:1.2, and add polydimethylsiloxane under anhydrous conditions The reaction was carried out for 10 hours at a temperature of 60°C;

[0030] Step 3: Take the liquid after the reaction in step 2, add isobutyl acrylate according to the molar ratio of the perfluoroalkyl ethyl alcohol content in the liquid to isobutyl acrylate is 1:3, and add 2% of the total weight of the reaction liquid Dibutyltin laurat...

Embodiment 2

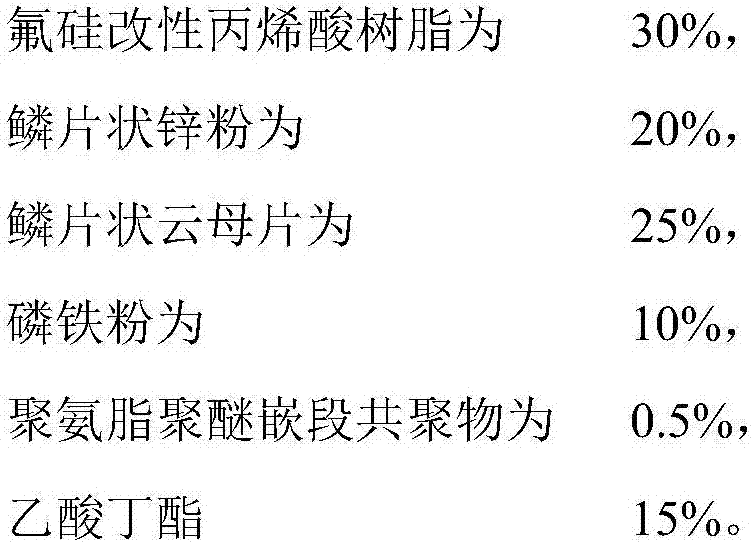

[0035] 1. The mass percentage of raw materials and dosage is

[0036]

[0037] 2. Preparation method

[0038] This example was prepared using exactly the same steps as Example 1.

[0039] The surface of the substrate was sanded with 120-grit sandpaper, degreased with acetone and dried. The paint is sprayed on the template by spraying process.

Embodiment 3

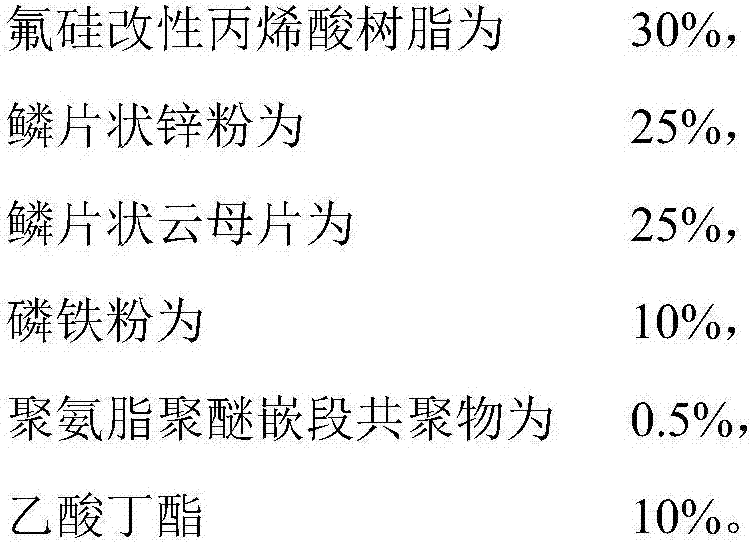

[0041] 1. The mass percentage of raw materials and dosage is

[0042]

[0043] 2. Preparation method

[0044] The preparation steps 1-4 of this example are prepared by the same steps as in Example 1. After the ingredients in step 5 are mixed evenly, they are ground by a sand mill to a fineness of less than 50 μm to obtain the anti-corrosion agent of fluorosilicon modified acrylic resin coating.

[0045] The surface of the substrate was sanded with 120-grit sandpaper, degreased with acetone and dried. The paint is sprayed on the template by spraying process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com