Preparation method for multi-amino magnetic gel based on hyperbranched polyglycidol

A technology of glycidol and hyperbranched polymers, which is applied in the field of preparation of polyamino magnetic gels, can solve the problems of detachment and loss of magnetic properties of magnetic gels, and achieve the effects of easy separation, mild reaction and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

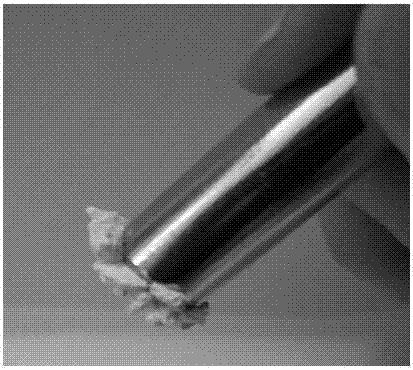

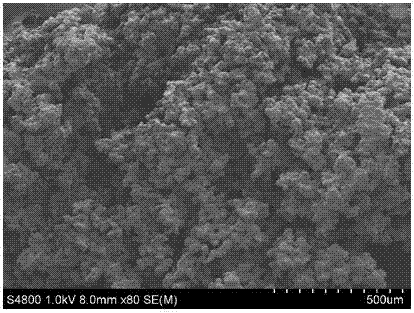

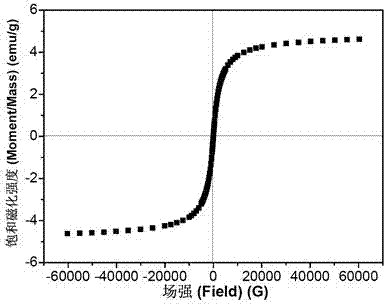

[0013] 1 gram of hyperbranched polyglycidol and 0.5 gram of iron ferric oxide nanoparticles coated with hyperbranched polyglycidol are added in 20 grams of dimethylformamide, and after stirring for 5 minutes, 6 grams of epichlorohydrin are added, and then After heating up to 90° C. and stirring for 2 hours, 5 g of diethylenetriamine was added, and stirring was continued at 90° C. for 60 minutes to obtain a polyamino magnetic gel based on hyperbranched polyglycidol.

Embodiment 2

[0015] 1 gram of hyperbranched polyglycidol and 0.4 gram of iron ferric oxide nanoparticles coated with hyperbranched polyglycidol were added to 10 grams of dimethylformamide, and 4 gram of epichlorohydrin was added after stirring for 5 minutes, and then After raising the temperature to 90° C. and stirring for 1 hour, 2 g of ethylenediamine was added, and the stirring was continued at 90° C. for 120 minutes to obtain a polyamino magnetic gel based on hyperbranched polyglycidol.

Embodiment 3

[0017] 1 gram of hyperbranched polyglycidol and 1 gram of iron ferric oxide nanoparticles coated with hyperbranched polyglycidol are added in 30 grams of dimethylformamide, and 10 grams of epichlorohydrin is added after stirring for 5 minutes, and then After heating up to 90° C. and stirring for 3 hours, 10 g of triethylenetetramine was added, and stirring was continued at 90° C. for 15 minutes to prepare a polyamino magnetic gel based on hyperbranched polyglycidol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com