Electric hub drive

A hub-driven, electric vehicle technology, applied in the field of electric vehicles, can solve the problems of inconvenient installation and disassembly, complex structure, large volume, etc., and achieve the effect of easy disassembly and maintenance, simple and compact structure, and stable output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

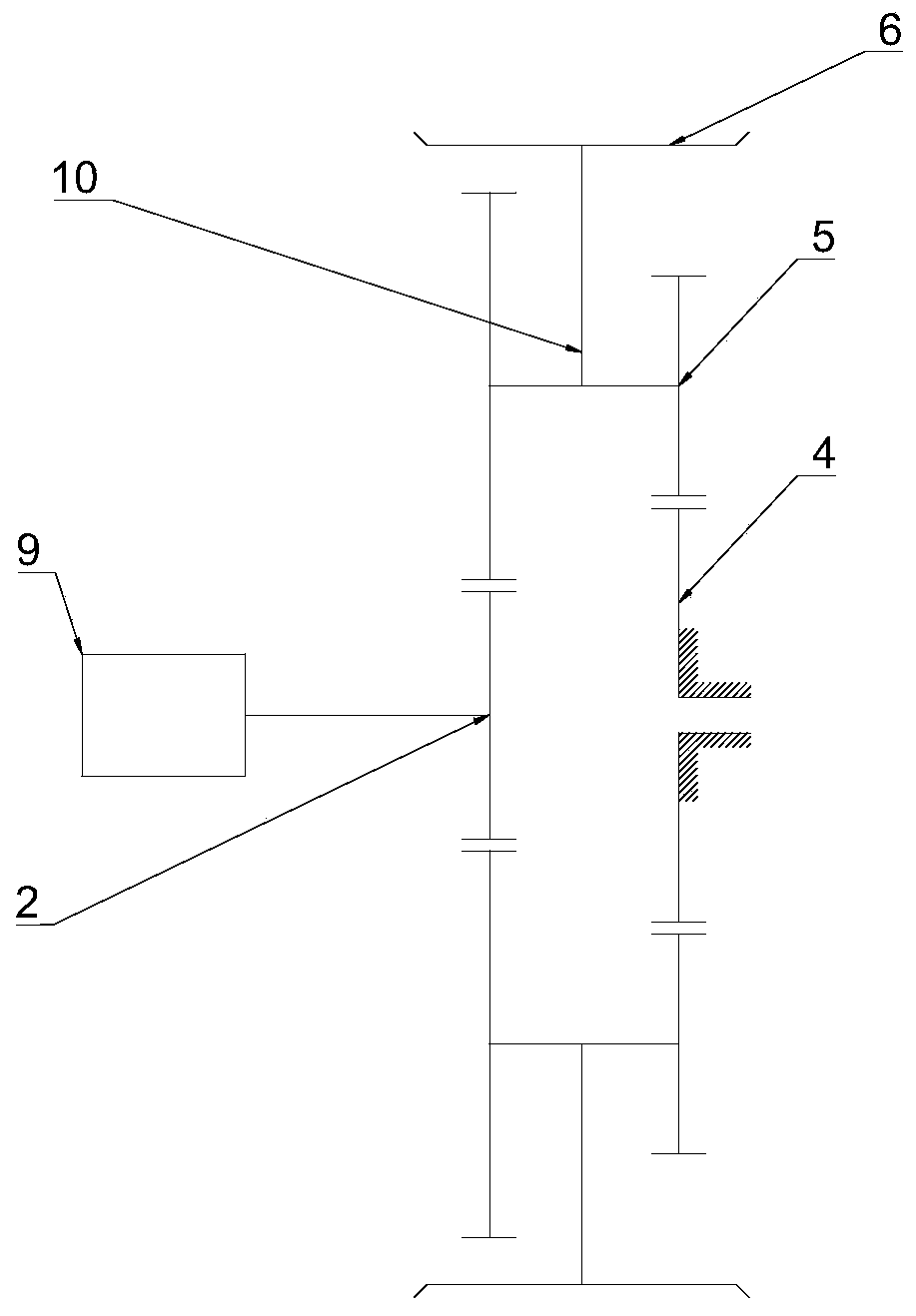

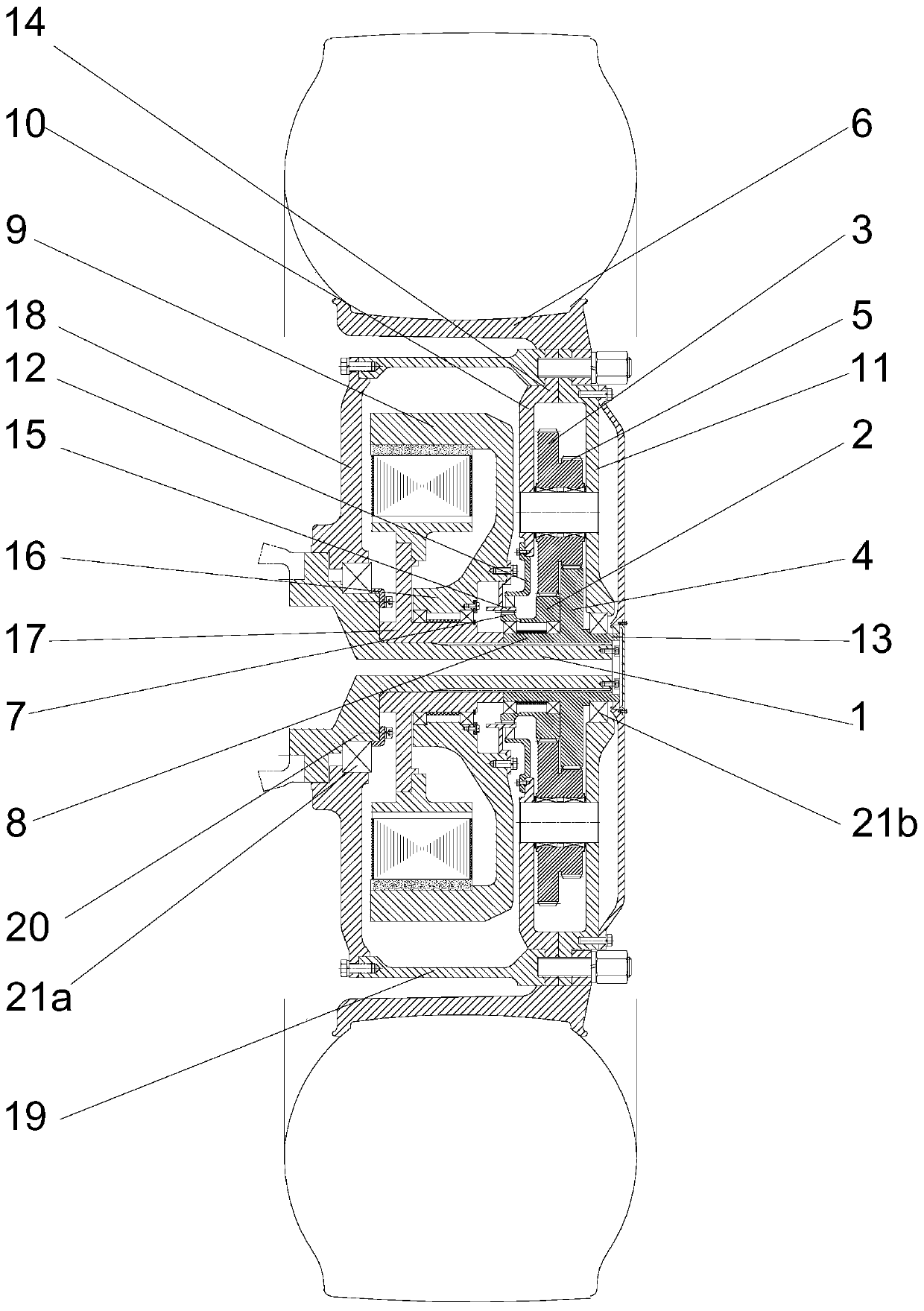

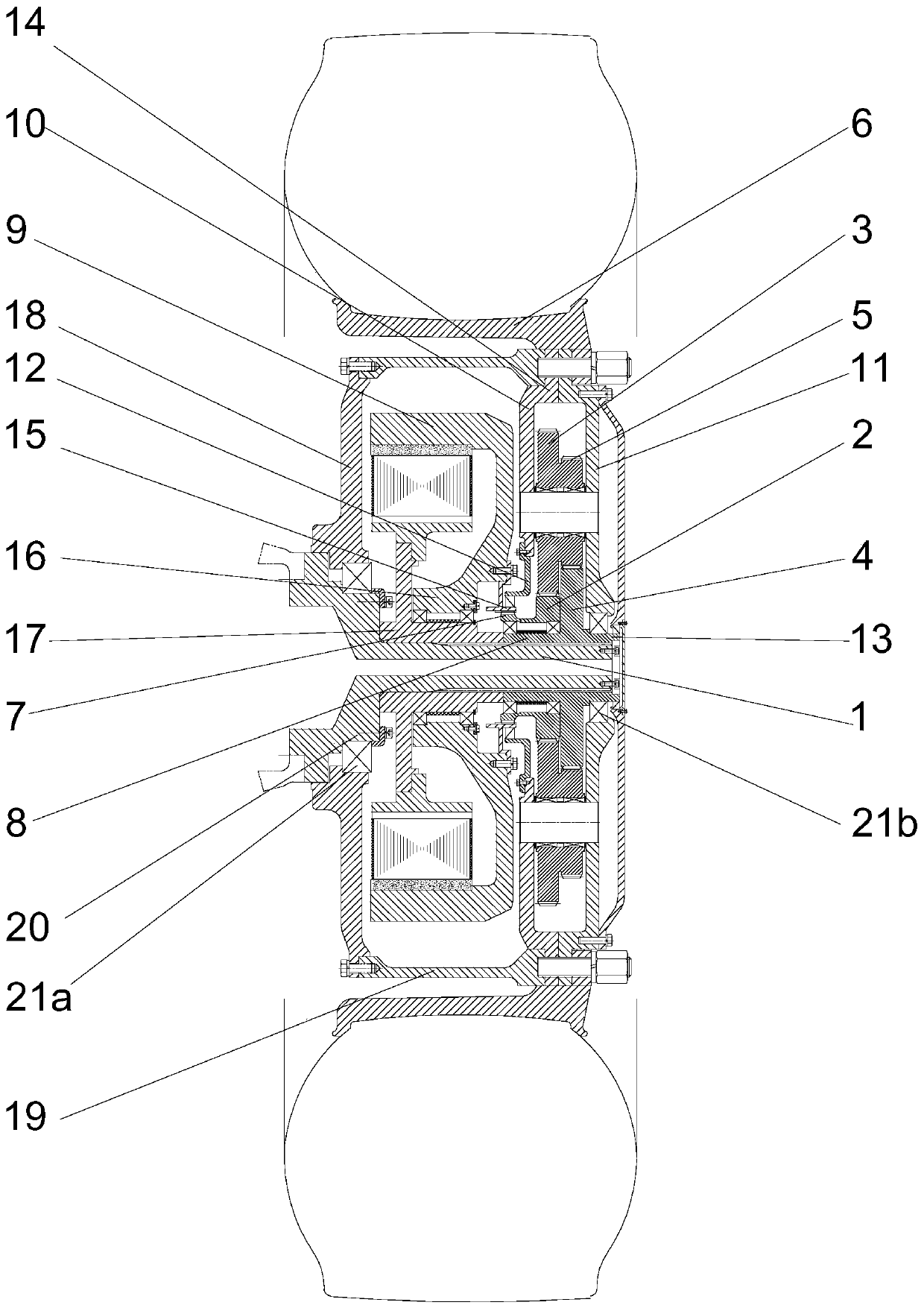

[0020] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a structural schematic diagram of the present invention. As shown in the figure, an electric wheel hub drive device provided by the present invention includes a main support shaft, a built-in motor installed on the main support shaft 1, and a planetary reduction mechanism. The planetary reduction mechanism includes a sun gear 2, a planetary gear set, The planet carrier and the center wheel fixed to the main support shaft 1 in the circumferential direction;

[0021] The sun gear 2 is rotatably sheathed on the main support shaft 1 and is used as the power input end of the planetary reduction mechanism to drive and cooperate with the output end of the built-in motor. The planetary gear set includes the first planetary gear 3 and the The center wheel 4 drives the second planetary gear 5 that cooperates, and the planetary carrier is fixedly connected with the wheel shaft of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com