Cold forging punch

A punching and cold forging technology, applied in forging presses, forging presses, forging/pressing/hammer devices, etc., can solve the problems of insufficient pressure and high energy consumption, improve manufacturing accuracy, ensure high precision forging and high rigidity performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples. In this embodiment, existing technologies can be used for specific development parts, so further details will not be described in this specification.

[0030] Example.

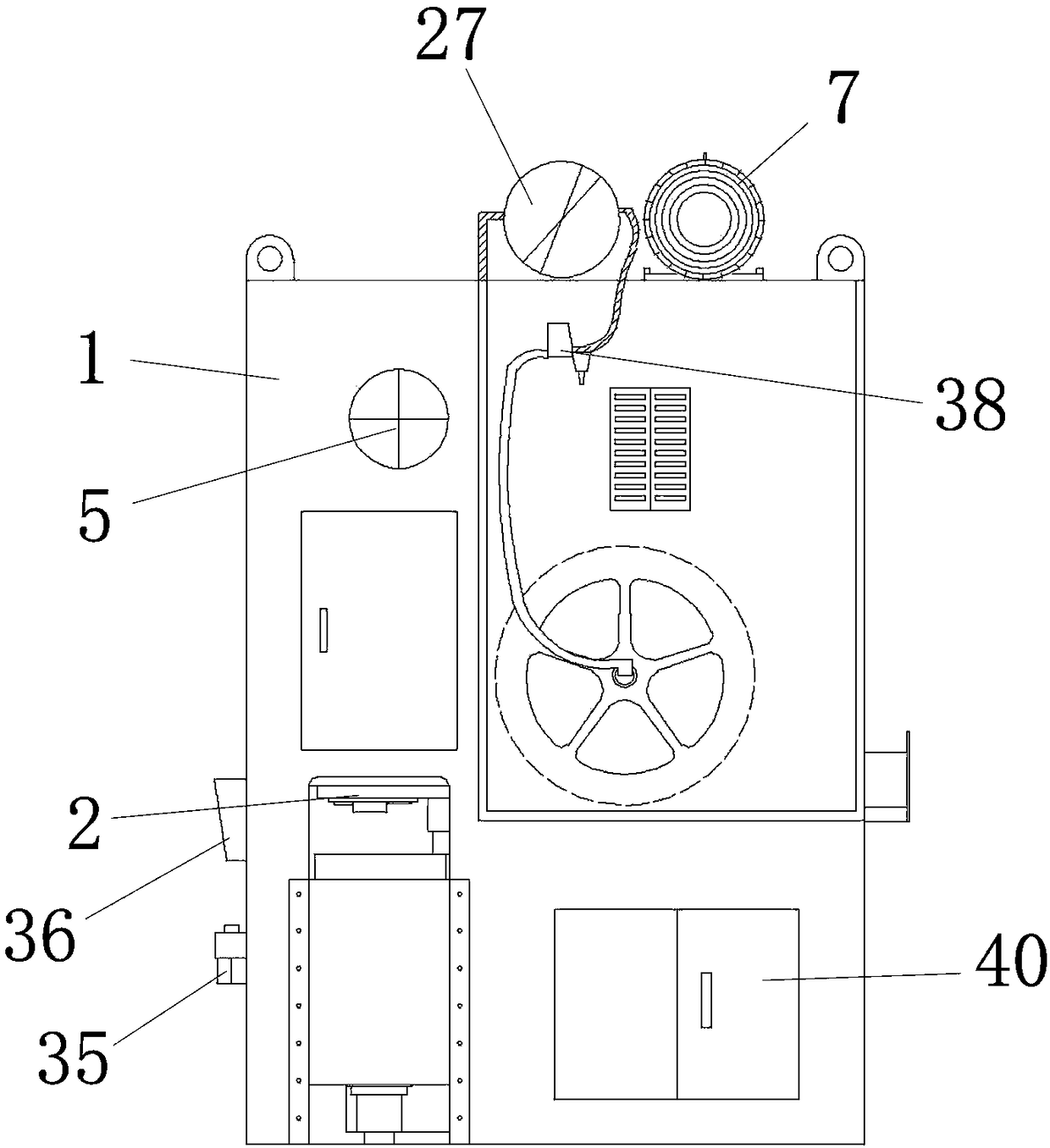

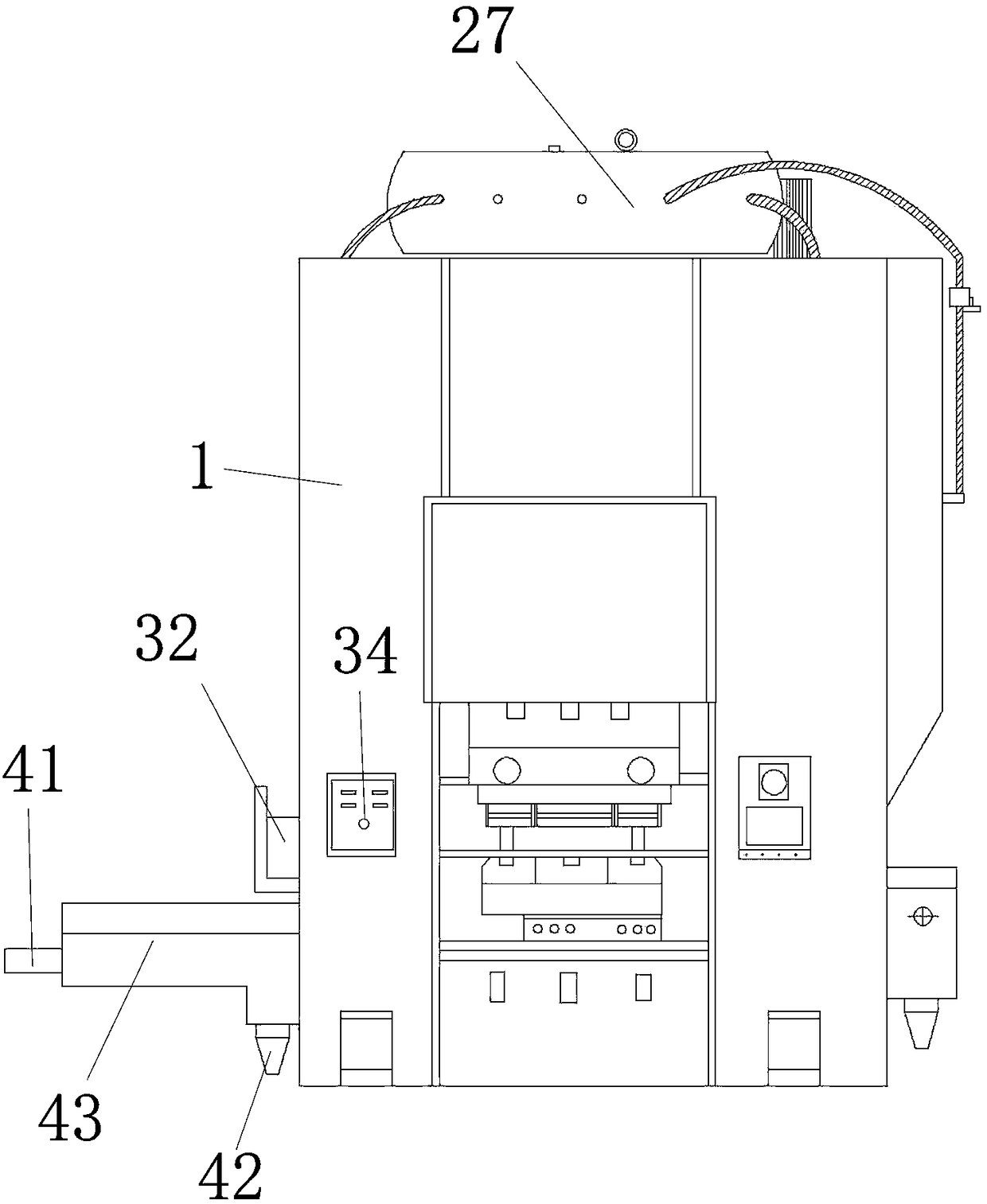

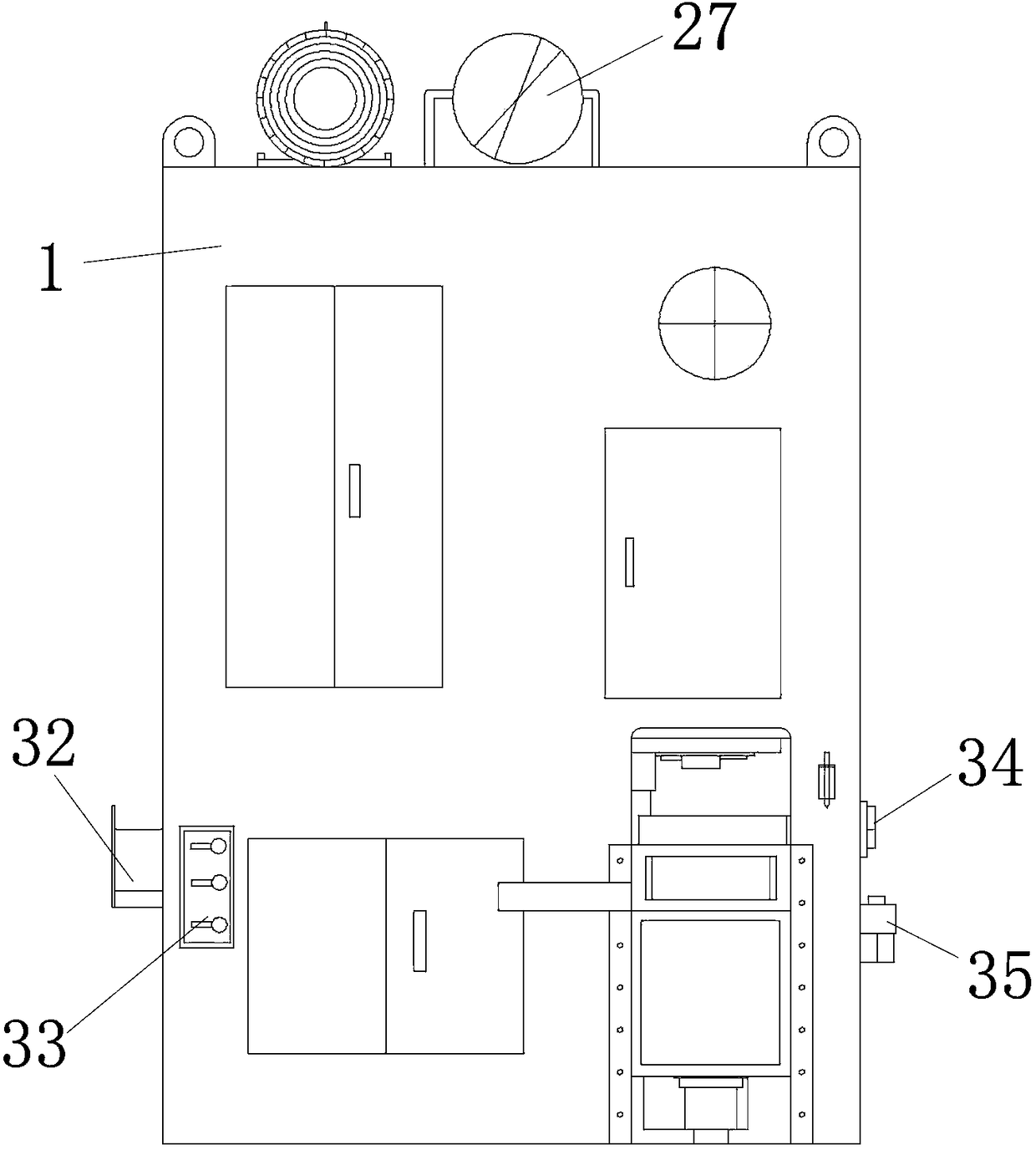

[0031] see Figure 1 to Figure 7 .

[0032] This embodiment is a toggle-type punch press, specifically a toggle-type cold forging punch press. The prior art is a common crankshaft punch press. The cold forging press of this embodiment includes a bed 1 and a drive mechanism, and the drive mechanism includes a slider 2, a gear mechanism, an upper toggle 3, a lower toggle 4, a main drive shaft 5, a clutch, a brake 6, and a slider adjustment device.

[0033] Bed 1 is a cuboid, and the interior of bed 1 is divided into bed front, bed rear, bed left and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com