Compact low-concentration organic waste gas treatment device

An organic waste gas and treatment device technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of high replacement cost, low purification degree, large floor space, etc., to facilitate inspection and maintenance, and reduce floor space. Area, the effect of strengthening the electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

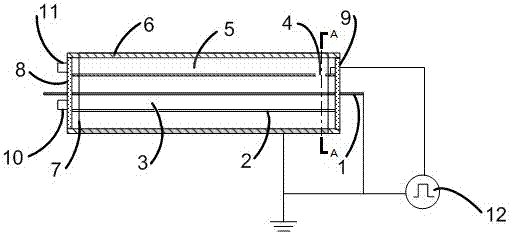

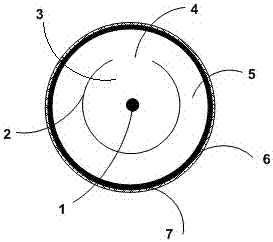

[0020] as attached Figure 1-2 As shown, a compact low-concentration organic waste gas treatment device has a structure including a metal wire 1, a metal cylinder 2, an inner air gap 3, an opening 4, an outer air gap 5, an insulating medium layer 6, a metal mesh 7, and an opening Sealing plug 8, sealing plug 9, air inlet 10, air outlet 11, pulse power supply 12; wherein the metal wire 1 is arranged inside the metal cylinder 2 and is coaxial with the metal cylinder 2 and the insulating medium layer 6, and the metal wire 1 is connected Pulse power supply 12 low-voltage end; metal cylinder 2 is set inside the insulating medium layer 6 and connected to the high-voltage end of pulse power supply 12; an inner air gap 3 is provided between the metal cylinder 2 and the metal wire 1, and the metal cylinder 2 and the insulating medium layer There is an outer air gap 5 between the 6; the upper right end of the metal cylinder 2 is provided with an opening 4; the metal mesh 7 is set close ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com