Six-dimensional force sensor

A six-dimensional force sensor and sensor technology, applied in instruments, measuring force components, measuring fluid pressure, etc., can solve problems such as high coupling degree of component force, high precision requirements of parts, and small Z-direction bearing load, etc., to achieve inter-dimensional The effect of low coupling degree, low precision requirement and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

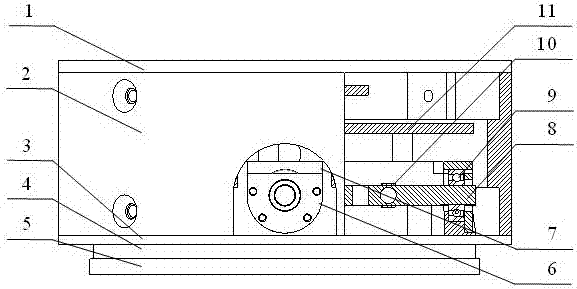

[0031] Such as figure 1 and figure 2 As shown, a six-dimensional force sensor with overload protection of the present invention includes an upper end cover 1, a housing 2, a sensor base 3, a rubber sealing ring 4, an overload protection mounting plate 5, a bearing end cover 6, and a bearing block 7 , elastic body 8, bearing 9, strain gauge 10, acquisition circuit board 11. Among them, the elastic body 8 is used to measure the three component forces F in the space coordinate system x , F y , F z and three moments M x ,M y ,M z . The upper end cover 1 and the sensor base 3 are parallel to each other and fixedly connected to two ends of the shell 2 respectively. The bearing end cover 6 and the bearing block 7 are fixedly connected to the sensor base 3 by bolts respectively, and the bearing 9 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com