Single-cell bio-based highly hydrophobic micron powder material and preparation method thereof

A single-cell, bio-based technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of complicated and cumbersome processes, low product strength, and limited application of highly hydrophobic materials. Achieve the effect of simple preparation steps and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

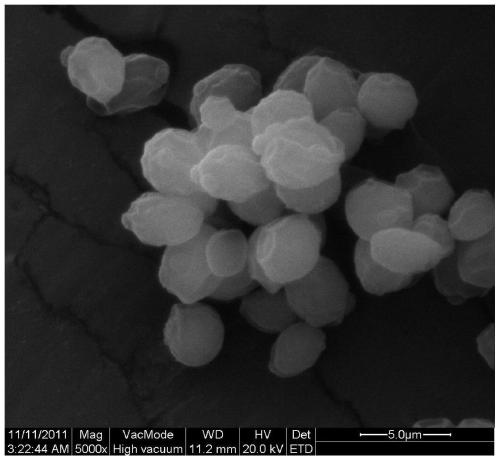

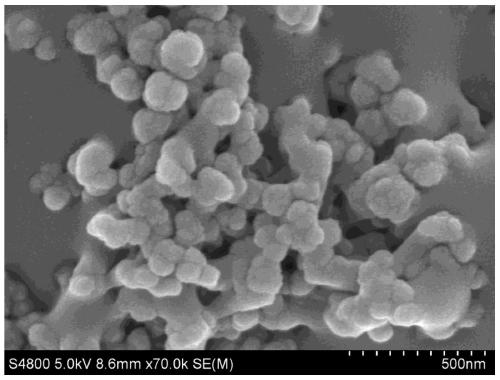

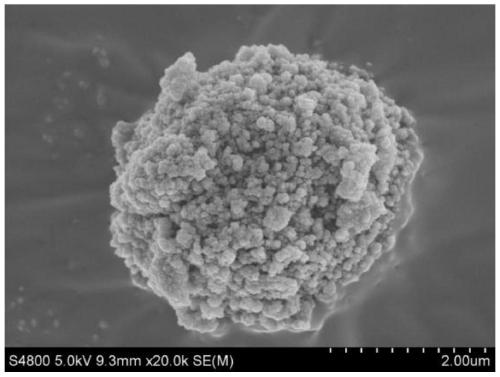

[0031] The invention provides a simple and efficient preparation method of single-cell bio-based highly hydrophobic micro-powder material. After the single-cell biological cells are repeatedly washed with a dispersant, the single-cell biological cells are activated with an activator to obtain activated Unicellular biological cells; at the same time, Fe can be prepared by a certain method 3 o 4 The nanoparticles are cleaned and modified to realize the combination of the nanoscale particles and the lectin molecules, and obtain the nanoparticles after the biomodification of the lectin molecules. Then, the biomodified nanoparticles of lectin molecules are combined with activated unicellular biological cells, and the Fc 3 o 4 The immobilization of nanoparticles on the surface of single-cell organisms realizes the construction of rough micro-nano structures on the surface of single-cell organisms, and then uses dopamine to modify the surface of the product with octadecylamine to f...

Embodiment 1

[0036] Weigh 1 g of yeast and wash it with deionized water, put the washed yeast into 0.1 mol / L phosphate buffer solution, stir and mix, let stand for 5 hours, activate the yeast cells by absorbing water, and obtain activated yeast cells.

[0037] 5g Fe will be prepared 3 o 4 Put the nanoparticles into a mixture containing 26% ammonia water, 30% hydrogen peroxide and distilled water (V:V:V=1:1:10) for ultrasonic cleaning, centrifugation and drying to achieve to Fe 3 o 4 Surface cleaning of nanoparticles.

[0038] The cleaned Fe 3 o 4 Put the nanoparticles into a beaker with a mass concentration of 2.5% glutaraldehyde solution and stir, mix well, let stand at room temperature for 20h, and then wash with phosphate buffer, distilled water and ethanol to obtain aldehyde-modified Fe 3 o 4 Nanoparticles.

[0039] Add 10mg Con A to 10ml containing 0.1mol / L KCl, 0.1mmol / L CaCl 2 , 0.1mmol / L MnCl 2 , and pH=7 in 0.1 mol / L phosphate buffer solution, mixed, stirred and activate...

Embodiment 2

[0045] Weigh 1 g of yeast and wash it with deionized water, put the washed yeast into 0.1 mol / L phosphate buffer solution, stir and mix, let stand for 4 hours, activate the yeast cells by absorbing water, and obtain activated yeast cells.

[0046] 2g of Fe will be prepared 3 o 4 Put the nanoparticles into a mixture containing 26% ammonia water, 30% hydrogen peroxide and distilled water (V:V:V=1:1:10) for ultrasonic cleaning, centrifugation and drying to achieve to Fe 3 o 4 Surface cleaning of nanoparticles.

[0047] The cleaned Fe 3 o 4 Put the nanoparticles into a beaker with a glutaraldehyde solution with a mass concentration of 2.5%, stir, mix well, let stand at room temperature for 16h, and then wash with phosphate buffer, distilled water and ethanol to obtain aldehyde-modified Fe 3 o 4 Nanoparticles.

[0048] Add 10mg Con A to 10ml containing 0.1mol / L KCl, 0.1mmol / L CaCl 2 , 0.1mmol / L MnCl 2 , and pH=7 in 0.1 mol / L phosphate buffer solution, mixed, stirred and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com