Resin Composition For Golf Ball Cover

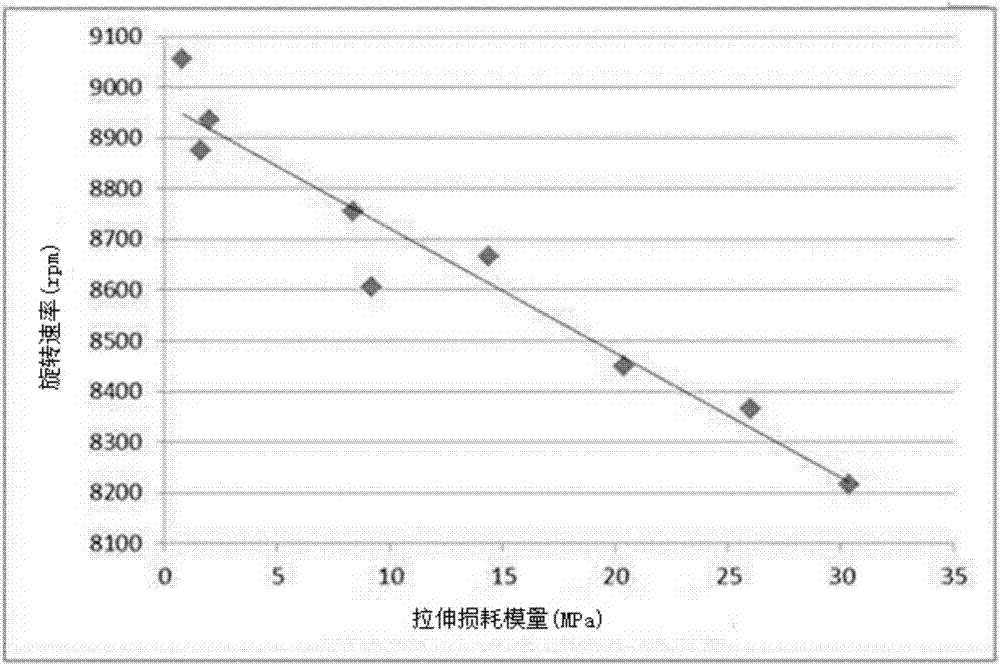

A technology of resin composition and golf balls, applied to balls, solid core balls, sports accessories, etc., can solve the problems of changes in the number of rotations and recovery characteristics, changes in physical properties, etc., to reduce performance deviations, reduce changes in physical properties, Effects of High Rotation Rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Preparation of test piece of resin composition for golf ball cover

[0048] Step 1: Preparation of Prepolymer

[0049] Toluene diisocyanate (BASF SE, T80, 208g), polytetramethylene glycol (Korean PTG company, PTMG2000, 597g), polypropylene glycol (SKC, DF-1000, 179g) and dipropylene glycol (SKC, DPG, 16g) were mixed and reacted at 80°C After 8 hours, a prepolymer with NCO end groups (weight average molecular weight 1700) was prepared.

[0050] Step 2: Preparation of test piece of resin composition containing non-reactive oligomer

[0051] The prepolymer with NCO end groups prepared in step 1 (1000 g), (nonyl)dioctyl terephthalate (100 g) as non-reactive oligomer and diethyltoluene as hardener Diamine (Lonza Group AG, Lonzacure DETDA80, 105g) was injected into a rectangular mold with a size of 20cm × 20cm and a thickness of 5mm, cured at 50°C for 20 minutes, demoulded from the mold, aged at room temperature for 24 hours, and prepared A test piece of ...

Embodiment 2

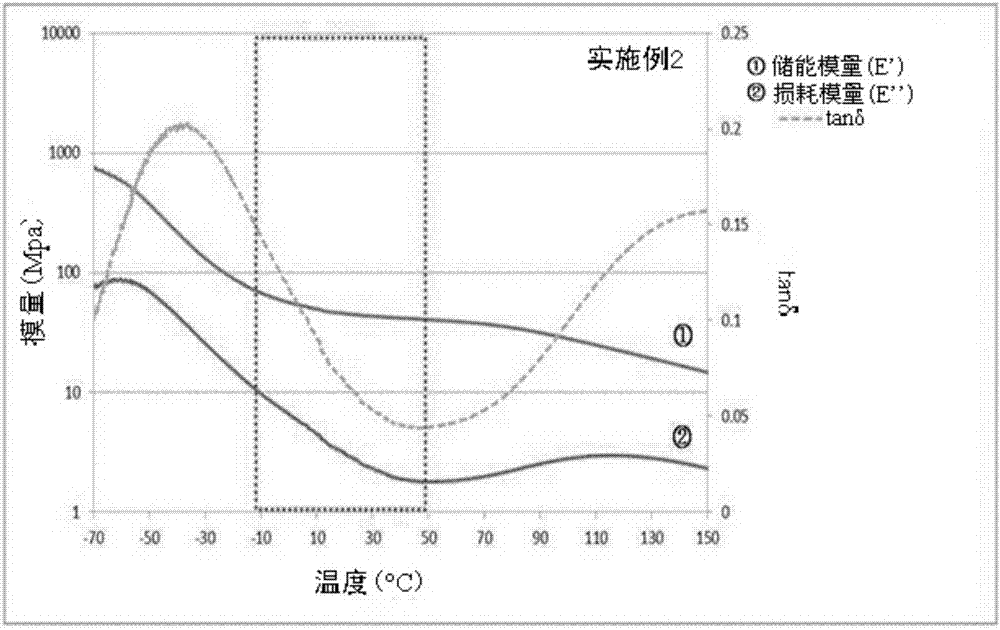

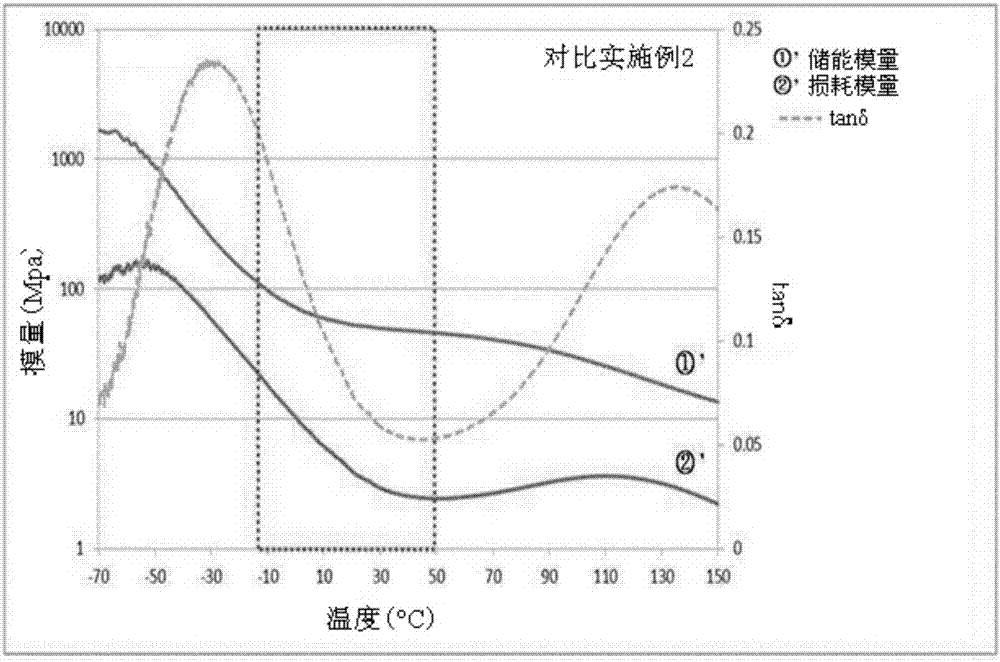

[0052] Example 2: Making Golf Balls Including Golf Ball Covers

[0053] Toluene diisocyanate (BASF SE, T80, 208g), polytetramethylene glycol (Korean PTG company, PTMG2000, 597g), polypropylene glycol (SKC, DF-1000, 179g) and dipropylene glycol (SKC, DPG, 16g) were mixed and reacted at 80°C After 8 hours, a prepolymer with NCO end groups (weight average molecular weight 1700) was prepared.

[0054] A prepolymer with NCO end groups (1000 g), (nonyl)dioctyl terephthalate (100 g) as a non-reactive oligomer and diethyltoluenediamine (Lonza Group AG , Lonzacure DETDA80, 105g) is injected around the golf core by casting method, cured at 50°C for 20 minutes, demoulded from the mold, and aged at room temperature for 24 hours to obtain a non-reactive oligomer containing The resin composition forms the cover layer of the golf ball.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com