Environmental protection technology for treating monosodium glutamate fermentation waste

A fermentation waste liquid and process technology, which is applied in the field of environmental protection technology for the treatment of monosodium glutamate fermentation waste liquid, can solve the problems of easy deposition of bacterial agents to the bottom of the pool, large amount of bacterial agents used, and increased bacterial strain pollution, etc., to achieve harmless and Recycling, strong cell adhesion, and the effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of environment-friendly process of controlling monosodium glutamate fermentation waste liquid, it comprises the steps:

[0021] The sewage first enters the sedimentation tank and stands still for 12 hours. The bottom filler of the sedimentation tank is river sand with a thickness of 50cm. The particle size of the river sand is 1mm, which can initially adsorb and precipitate some flocculation impurities; Adjust the pH to 5 by adding ammonia water; then enter the phytoremediation tank, the repair time is 48h; then enter the microbial reaction tank, add 2 grams of microbial preparations per cubic meter of liquid, once a day, continuous dosing 5 days, then stand still for 3 days, and finally filter and discharge through a plate and frame filter; the plate and frame filter is used to collect microbial cells to avoid pollution to water bodies.

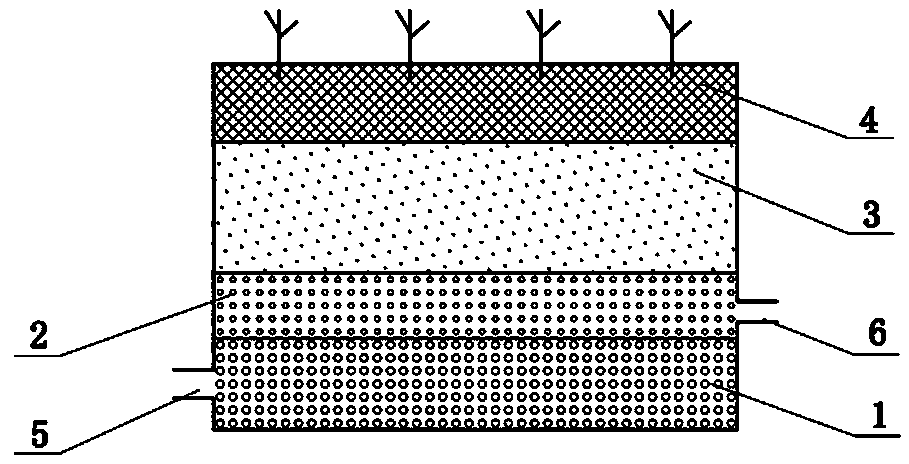

[0022] Such as figure 1 As shown, the phytorehabilitation pool is successively laid down from the bottom of the pool to a co...

Embodiment 2

[0029] A kind of environment-friendly process of controlling monosodium glutamate fermentation waste liquid, it comprises the steps:

[0030]The sewage first enters the sedimentation tank and stands still for 12 hours. The bottom filler of the sedimentation tank is river sand with a thickness of 50cm. The particle size of the river sand is 1mm, which can initially adsorb and precipitate some flocculation impurities; Adjust the pH to 8 by adding ammonia water; then enter the phytoremediation pool, the restoration time is 48 hours; then enter the microbial reaction pool, add 2 grams of microbial preparations per cubic meter of liquid, once a day, continuous dosing 5 days, then stand still for 3 days, and finally filter and discharge through a plate and frame filter; the plate and frame filter is used to collect microbial cells to avoid pollution to water bodies.

[0031] Such as figure 1 As shown, the phytorehabilitation pool is successively laid down from the bottom of the poo...

Embodiment 3

[0038] Example of the effect of the process of the present invention on the treatment of fermentation waste liquid:

[0039] Take the monosodium glutamate fermentation waste liquid (COD is 1327.2mg / L, ammonia nitrogen 201.7mg / L, sulfide 69.4mg / L) from the production workshop of Fufeng, Inner Mongolia, and take the process of Example 1 as an example to measure COD, ammonia nitrogen, and sulfide data; and a control group is set to detect the compatibility effect of each bacterial strain in the bacterial agent: control group 1: do not add Bacillus xylosoxidans, all the other are the same as Example 1; control group 2: do not add Micrococcus luteus, all the other are the same as the embodiment 1; Control group 3: without adding Nocardia corals, the rest is the same as in Example 1; Control group 4: without adding Cellulomonas, and the rest is the same as in Example 1. The specific test results are shown in Table 1:

[0040] Table 1

[0041] Example 1 (mg / L) Control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com