Intelligent four-way rail car coil conveying system

A rail car, intelligent technology, applied in the direction of transportation and packaging, conveyor control devices, conveyor objects, etc., can solve the problems of low efficiency, high energy consumption, artificial bumping, etc., to achieve low efficiency, simplify the transportation process, save The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

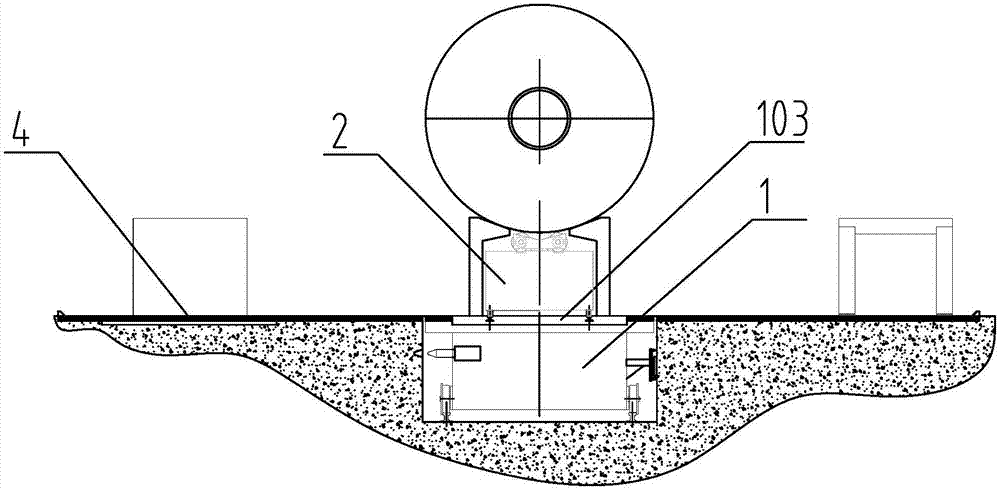

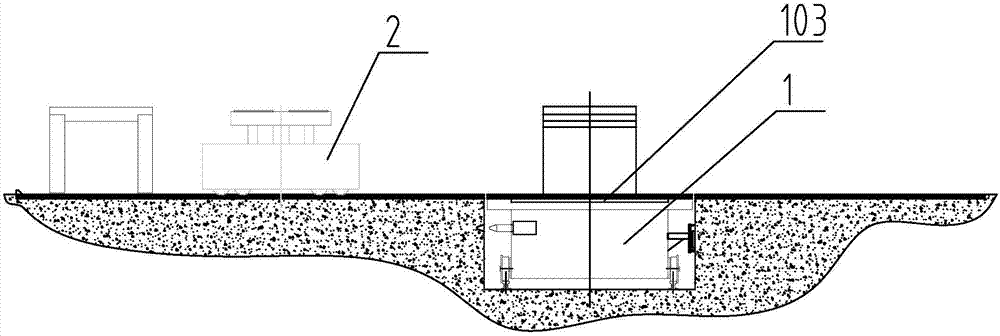

[0037] Embodiment 1: Combining figure 1 – Image 6 explain the implementation,

[0038] Intelligent four-way rail car roll system, including several parent cars 1 and several sub-cars 2, one parent car 1 corresponds to several sub-cars 2, but one sub-car 2 only belongs to the corresponding parent car 1, the sub-car 2 and the corresponding sub-car 2 The parent car 1 communicates wirelessly, and the child car 2 obeys and serves the corresponding parent car;

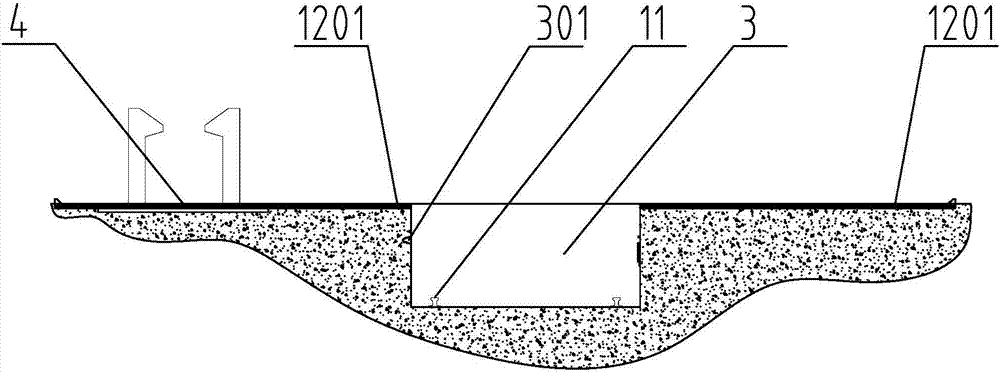

[0039] The rail car roll conveying system also includes a parent car track 11, a ground sub-car track 1201, a ground steering wheel 4 with a coil saddle, and a ground steering sub-car track 1202; the movement plane of the sub-car during operation is used as the benchmark as the ground. , the ground sub-car track 1201 is embedded in the ground, that is, the ground sub-car track 1201 is embedded in the ground, and the upper surface of the ground and the upper surface of the ground sub-car track 1201 are on the same level; ...

specific Embodiment approach 2

[0051] In this embodiment, several parent car running trenches 3 are arranged in one line, and ground sub-car tracks 1201 and at least one coil saddle fixed to the ground are arranged between two sections of parent car running trenches 3. When the material coil needs to be delivered and transported At the same time, several parent cars 1 are located on the parent car tracks 11 in their respective parent car running ditch 3, and the sub car rolls are disembarked from the parent car from the end of the parent car running ditch and drive into the ground sub car track 1201 and run to the ground The coil saddle is dropped on it, and another set of sub-mother cars running in the ditch and lane of the adjacent mother car undertakes in the same way to complete the delivery of the coil material. The present invention can transport the coil to any position by means of delivery, which avoids that the existing coil movement method cannot be sent to any position or requires the cooperation ...

specific Embodiment approach 3

[0054] The system described in this embodiment also includes a system control center station, which communicates with the parent car 1 through the leaky wave cable, so as to control the parent car 1 and the sub-cars 2 according to the requirements for rolling. The invention can participate in the deployment of coiled material through the system control center station to realize intelligent control.

[0055] Other structures are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com